In the context of ultra-low temperature (ULT) freezers, pull-down time is the specific duration required for the unit to cool from ambient room temperature down to its operational setpoint, typically between -80°C and -86°C. This initial performance test is a key indicator of the freezer's overall efficiency, which is dictated by the quality of its core components like the compressor system and insulation. While older models from the early 2000s took 3 to 5 hours, modern units can vary based on their design and features.

Pull-down time is more than just a setup metric; it's a direct indicator of a ULT freezer's cooling system efficiency and thermal integrity. While a fast pull-down is convenient, it's the underlying factors—insulation and compressor power—that truly determine the freezer's long-term reliability and its ability to protect valuable samples.

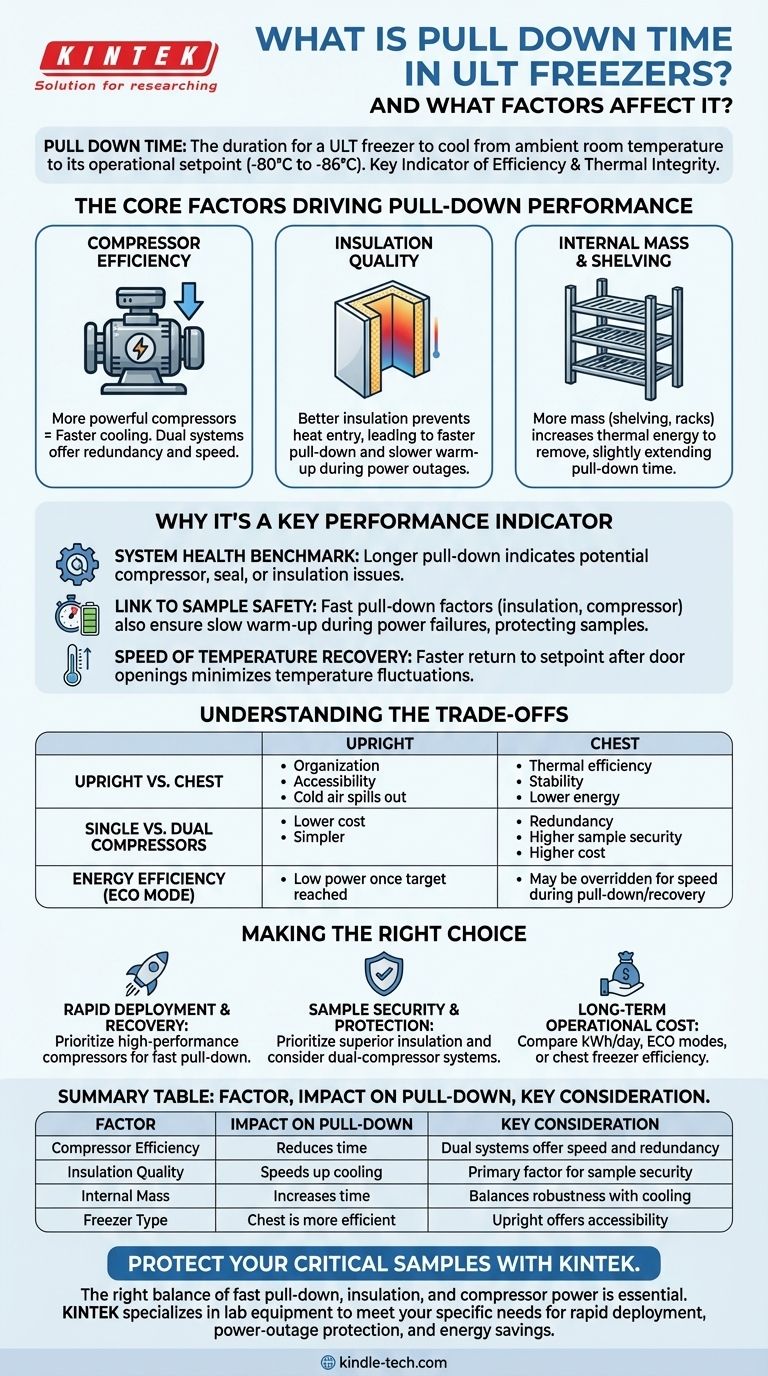

The Core Factors Driving Pull-Down Performance

The time it takes for a ULT freezer to reach its target temperature is not arbitrary. It is the direct result of a few key engineering and design choices.

Compressor Efficiency

The compressor system is the engine of the freezer, responsible for actively removing heat from the insulated cabinet.

More powerful and efficient compressors can extract heat at a faster rate, resulting in a shorter pull-down time. Some high-performance or redundant models may use dual-compressor systems, which can significantly impact cooling speed and provide critical backup.

The Critical Role of Insulation

Insulation works to prevent ambient heat from entering the freezer. The better the insulation, the less work the compressor has to do to reach and maintain the target temperature.

Advanced insulation not only contributes to a faster pull-down but is also the primary factor determining the warm-up time during a power failure. Superior insulation slows the rate of temperature increase, giving you more time to react.

Internal Mass and Shelving

Every component inside the freezer must also be cooled from ambient to -80°C. This includes the air, but also all installed metal shelves and racks.

The more internal mass a freezer has, the more thermal energy must be removed. Heavy-duty shelving, while robust, will slightly increase the time required for the initial pull-down.

Why Pull-Down Time Is a Key Performance Indicator

While it seems like a one-time metric, pull-down time provides crucial insight into a freezer's overall health, reliability, and ability to protect its contents.

A Benchmark for System Health

The manufacturer's specified pull-down time serves as a vital performance benchmark. If a new freezer takes significantly longer than specified, it may indicate a problem from shipping or manufacturing.

For an existing unit, a progressively longer pull-down time after a defrost or relocation can be an early warning sign of a failing compressor or compromised door seals and insulation.

The Link to Sample Safety During Power Failure

The factors that enable a fast pull-down—strong compressors and excellent insulation—are the same ones that protect your samples when the power goes out.

Good insulation is paramount, leading to a slow warm-up rate (e.g., 1/8°C per minute). This creates a critical window of time for facility staff to respond to alarms before samples are compromised.

Speed of Temperature Recovery

Beyond the initial setup, a freezer's ability to pull its temperature down quickly is important for operational recovery.

After routine door openings or adding new, room-temperature samples, a system with a fast recovery time will return to its safe setpoint more quickly, minimizing temperature fluctuations and risk to stored materials.

Understanding the Trade-offs

Choosing a ULT freezer involves balancing performance, cost, and convenience. The factors affecting pull-down time are central to these compromises.

Upright vs. Chest Freezers

Chest freezers are generally more thermally efficient. Because cold air is dense, it remains inside when the lid is opened, leading to better temperature stability and lower energy consumption.

Upright freezers offer superior organization and accessibility. However, cold air "spills out" each time the door is opened, forcing the compressor to work harder to recover and increasing energy usage.

Single vs. Dual Compressors

A dual-compressor system provides redundancy, which is the ultimate in sample security. If one compressor fails, the other can typically maintain the setpoint temperature indefinitely.

This security comes at the cost of higher upfront price, greater complexity, and often higher energy consumption compared to a single-compressor model.

Energy Efficiency (ECO Mode)

Many modern freezers feature an energy-saving or ECO mode. This function typically runs the compressors at a lower power setting once the target temperature is reached, significantly reducing long-term electricity costs.

However, this mode may be temporarily overridden by the system during a pull-down or temperature recovery phase to ensure speed when it is most needed.

Making the Right Choice for Your Goal

When evaluating a ULT freezer, use pull-down time as a clue to its underlying design and prioritize features based on your lab's specific needs.

- If your primary focus is rapid deployment and recovery: Prioritize a model with high-performance compressors and a documented fast pull-down time, which is useful after relocations or deep cleaning.

- If your primary focus is sample security and power-outage protection: Look for superior insulation (leading to slow warm-up times) and strongly consider a dual-compressor system for redundancy.

- If your primary focus is long-term operational cost: Compare the energy consumption (kWh/day) figures and evaluate models with advanced ECO modes or consider the inherent efficiency of a chest freezer.

Ultimately, understanding pull-down time is the first step toward evaluating the fundamental engineering that will protect your critical samples for years to come.

Summary Table:

| Factor | Impact on Pull-Down Time | Key Consideration |

|---|---|---|

| Compressor Efficiency | More powerful compressors reduce time. | Dual-compressor systems offer speed and redundancy. |

| Insulation Quality | Superior insulation speeds up cooling and improves warm-up time during outages. | Primary factor for long-term sample security. |

| Internal Mass (Shelving) | More mass (e.g., heavy racks) increases the time required. | Balances robustness with initial cooling performance. |

| Freezer Type (Upright vs. Chest) | Chest freezers are generally more thermally efficient. | Upright offers accessibility; chest offers stability. |

Protect your critical samples with a ULT freezer engineered for performance and reliability. The right balance of fast pull-down time, superior insulation, and compressor power is essential for your lab's efficiency and sample security. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the ideal ULT freezer to meet your specific requirements for rapid deployment, power-outage protection, or energy savings. Contact KINTEK today for a consultation and ensure your valuable research is safeguarded.

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C