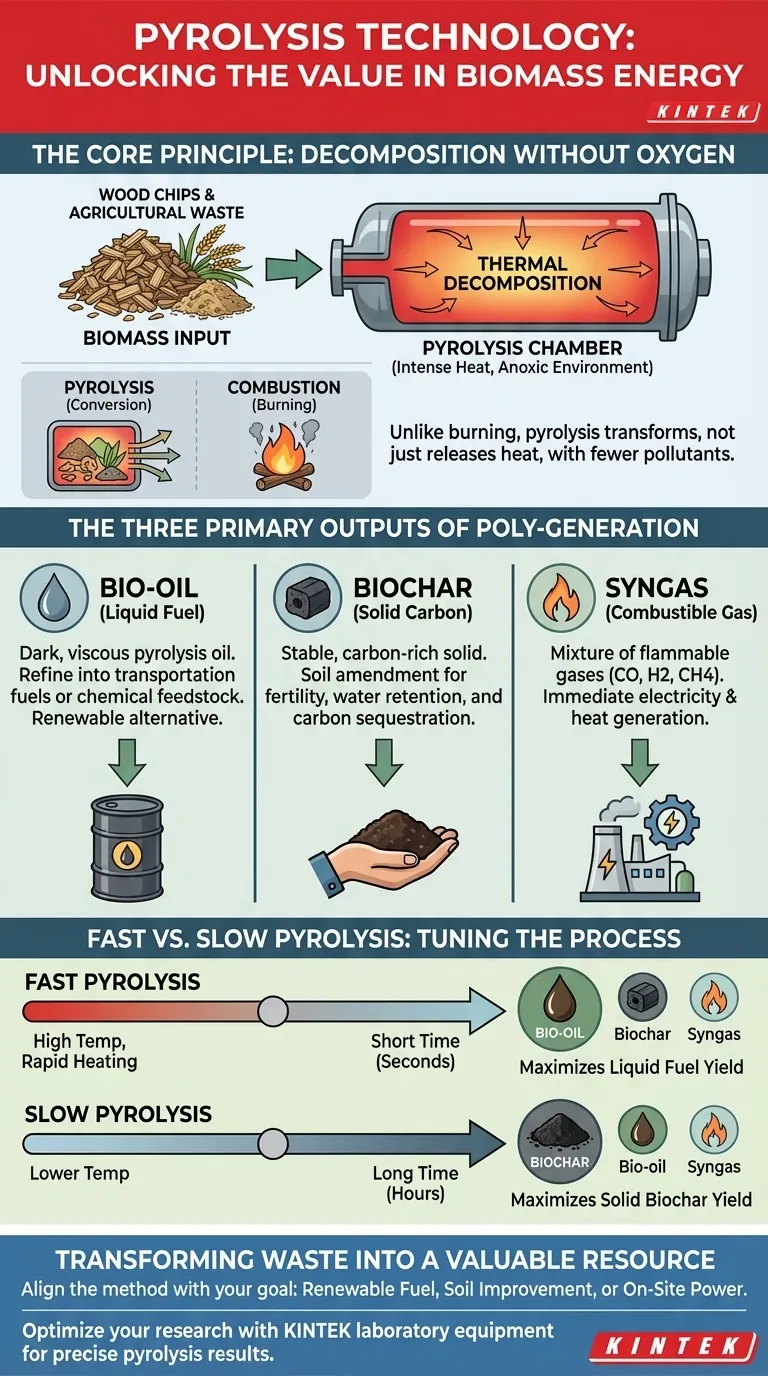

At its core, pyrolysis is a thermochemical process that converts biomass into energy and valuable by-products by heating it in an oxygen-free environment. Unlike simple burning, which uses oxygen to release heat, pyrolysis chemically decomposes organic materials like wood chips or agricultural waste into bio-oil, biochar, and syngas, transforming a low-value material into multiple high-value resources.

The crucial insight is that pyrolysis is not just an alternative energy source; it is a "poly-generation" technology. It unlocks the chemical value locked within biomass, creating a portfolio of marketable products while offering significant environmental benefits over traditional combustion.

How Pyrolysis Works: Beyond Simple Burning

Pyrolysis represents a more refined approach to energy conversion. It operates on principles fundamentally different from incineration or direct combustion.

The Core Principle: Decomposition Without Oxygen

Imagine heating wood in a sealed container. Instead of catching fire, the intense heat breaks the complex organic matter down into simpler, more valuable components. This is thermal decomposition in an anoxic (oxygen-free) or nearly oxygen-free environment.

This process prevents the biomass from simply burning into ash and smoke. Instead, it is systematically deconstructed into a liquid (bio-oil), a solid (biochar), and a gas (syngas).

The Key Distinction from Combustion

Combustion (burning) is an oxidation reaction. It requires oxygen to rapidly release energy as heat, producing carbon dioxide, water, and pollutants like particulate matter and nitrogen oxides.

Pyrolysis is a conversion process. By withholding oxygen, it transforms the biomass itself, preserving its chemical components in new, more useful forms. This results in significantly fewer pollutants.

The Concept of "Pyrolysis Gasification"

You may encounter the term "pyrolysis gasification," sometimes called two-stage combustion. This is a highly efficient application of the technology.

In this process, the initial pyrolysis stage is optimized to produce combustible gases—carbon monoxide, hydrogen, and methane. These gases can then be immediately used for clean and efficient power or heat generation.

The Three Primary Outputs of Pyrolysis

The genius of pyrolysis is that it creates three distinct product streams from a single input, each with its own market and application.

Bio-oil: The Liquid Fuel

This dark, viscous liquid is often called pyrolysis oil. It is a complex mixture of organic compounds that can be refined into transportation fuels or used as a feedstock for producing specialty chemicals. It is the primary target of fast and flash pyrolysis.

Biochar: The Solid Carbon

Biochar is a stable, carbon-rich solid that resembles charcoal. Its primary application is as a soil amendment, where it can improve water retention, reduce nutrient runoff, and enhance soil fertility. It also serves as a method for long-term carbon sequestration.

Syngas: The Combustible Gas

Syngas, or synthesis gas, is a mixture of flammable gases. It can be combusted directly in a gas engine or turbine to generate electricity and heat, providing an immediate energy return from the process.

Understanding the Trade-offs: Fast vs. Slow Pyrolysis

The specific outputs of pyrolysis can be controlled by adjusting the process parameters. The choice between methods depends entirely on the desired end product.

Fast Pyrolysis: Maximizing Liquid Fuel

This method uses very high temperatures and rapid heating rates. The goal is to quickly vaporize the biomass and then rapidly cool the vapors to condense them into liquid bio-oil, maximizing its yield.

Slow Pyrolysis: Maximizing Solid Biochar

In contrast, slow pyrolysis uses lower temperatures over a much longer period (hours instead of seconds). This environment favors the formation of a stable, carbon-rich solid, maximizing the yield of biochar.

The Economic and Environmental Equation

The decision between fast and slow pyrolysis is a strategic one. If the goal is to produce renewable liquid fuels to displace fossil fuels, fast pyrolysis is the clear choice.

If the goal is agricultural improvement or carbon sequestration, slow pyrolysis is superior. Both methods produce all three outputs, but tuning the process changes their ratios, allowing operators to align production with market demands or environmental goals.

Making the Right Choice for Your Goal

To apply this technology effectively, you must align the pyrolysis method with your specific objective.

- If your primary focus is renewable liquid fuel production: Implement fast or flash pyrolysis to maximize the yield of bio-oil for refining or chemical synthesis.

- If your primary focus is soil improvement and carbon sequestration: Prioritize slow pyrolysis to generate the highest possible quantity of stable, high-quality biochar.

- If your primary focus is on-site power generation from waste: A pyrolysis gasification system is the most direct path to converting biomass into combustible syngas for heat and electricity.

Ultimately, pyrolysis technology redefines our perception of waste, transforming it from a disposal problem into a valuable resource.

Summary Table:

| Pyrolysis Output | Primary Use | Key Benefit |

|---|---|---|

| Bio-oil | Liquid fuel, chemical feedstock | Renewable alternative to fossil fuels |

| Biochar | Soil amendment, carbon sequestration | Improves soil health, locks away carbon |

| Syngas | Electricity, heat generation | Clean, immediate energy from biomass |

Ready to transform your biomass into valuable resources? KINTEK specializes in laboratory equipment and consumables for pyrolysis research and development. Whether you're optimizing bio-oil yield or producing high-quality biochar, our solutions help you achieve precise, efficient results. Contact us today to discuss how we can support your sustainable energy goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- How are optical coatings applied? Achieve Precision with Advanced Vacuum Deposition Methods

- What is the CVD growth process? A Step-by-Step Guide to Chemical Vapor Deposition

- What are the disadvantages of sputter deposition? Key Limitations in Thin Film Technology

- What are the advantages of ion beam deposition? Achieve Superior Thin Film Quality and Control

- What is deposition techniques? A Guide to PVD vs. CVD for Thin-Film Applications

- What is CVD graphene? The Scalable Method for High-Quality, Single-Layer Graphene Production

- What is sputter damage? A Guide to Protecting Sensitive Materials During Thin-Film Deposition

- Which synthesis method is used for preparation of nanotubes? Master Scalable Production with CVD