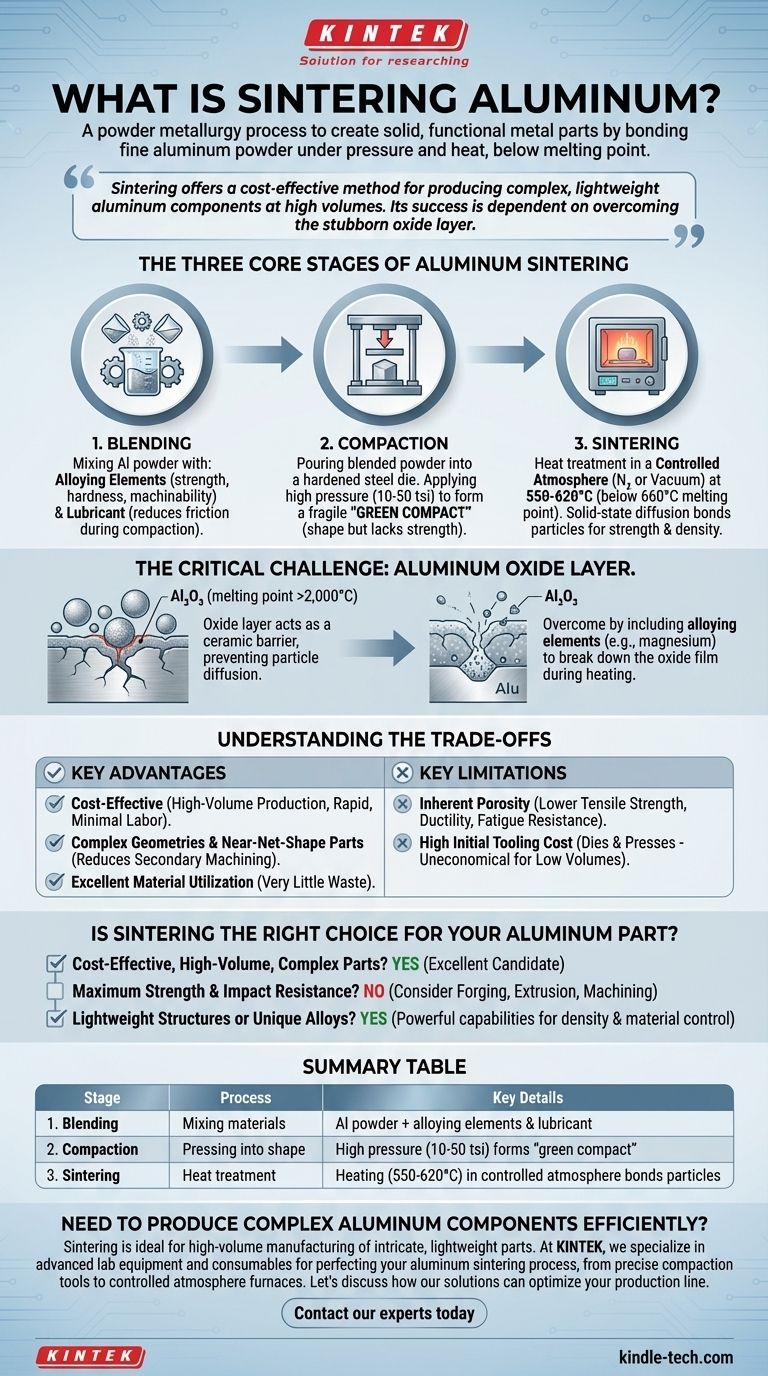

In essence, sintering aluminum is a powder metallurgy process used to create solid, functional metal parts without melting the material. It involves taking fine aluminum powder, pressing it into a specific shape under immense pressure, and then heating it in a controlled atmosphere to a temperature just below its melting point, causing the individual particles to bond and fuse together.

Sintering offers a cost-effective method for producing complex, lightweight aluminum components at high volumes. Its success, however, is critically dependent on overcoming the stubborn, naturally occurring oxide layer on the aluminum powder, which can prevent proper bonding.

The Three Core Stages of Aluminum Sintering

The process, while technically sophisticated, can be understood as three distinct manufacturing steps. Each stage is crucial for achieving the final part's desired mechanical properties and dimensional accuracy.

Step 1: Blending

Before anything is pressed, the raw material is prepared. This involves mixing fine aluminum powder with other elements.

Alloying elements like copper, silicon, or magnesium are added to enhance properties such as strength, hardness, and machinability.

A lubricant is also blended in to reduce friction during the compaction stage, ensuring the powder flows evenly within the die and the finished part can be ejected smoothly.

Step 2: Compaction

The precisely blended powder is then poured into a hardened steel die that is the negative of the final part's shape.

A powerful press applies extreme pressure (typically ranging from 10 to 50 tons per square inch), compacting the loose powder into a cohesive, albeit fragile, object.

This resulting part is known as a "green compact." It has the shape and dimensions of the final product but lacks the strength, as the particles are only held together by mechanical friction.

Step 3: Sintering

This is the critical heat treatment phase that transforms the fragile green compact into a robust metal part.

The green compact is placed in a furnace with a tightly controlled atmosphere (often nitrogen-based or a vacuum) to prevent unwanted oxidation.

It is heated to a temperature between 550°C and 620°C, which is below aluminum's melting point of 660°C. This thermal energy causes the atoms at the particles' surfaces to diffuse, creating strong metallurgical bonds where they touch. This process, known as solid-state diffusion, is what gives the part its final strength and density.

The Critical Challenge: The Aluminum Oxide Layer

Unlike many other metals, aluminum presents a unique and significant challenge for sintering due to its chemistry.

What is the Oxide Layer?

When exposed to air, aluminum instantly forms a very thin, hard, and chemically stable layer of aluminum oxide (Al₂O₃) on its surface.

Why It's a Problem

This oxide layer has a melting point of over 2,000°C, far higher than that of pure aluminum. It acts as a ceramic barrier, preventing the metal atoms of adjacent particles from making direct contact and diffusing during the sintering process.

How It's Overcome

Successfully sintering aluminum requires specific strategies to disrupt this oxide layer. This is often achieved by including certain alloying elements, like magnesium, which can react with and break down the oxide film during heating, allowing the pure aluminum underneath to bond.

Understanding the Trade-offs

Sintering is a powerful manufacturing method, but it is not universally superior. Understanding its pros and cons is key to making an informed decision.

Key Advantages

The primary benefit is cost-effectiveness for high-volume production. Once the tooling is made, parts can be produced rapidly with minimal labor.

Sintering excels at creating complex geometries and near-net-shape parts, drastically reducing or eliminating the need for secondary machining operations.

The process has excellent material utilization, with very little powder being wasted compared to subtractive methods like machining.

Key Limitations

Sintered parts almost always retain some level of inherent porosity. This results in lower tensile strength, ductility, and fatigue resistance compared to parts made from wrought, cast, or forged aluminum.

The high initial cost of the tooling (dies and presses) makes sintering uneconomical for low-volume production runs or prototyping.

Is Sintering the Right Choice for Your Aluminum Part?

To decide if this process fits your needs, evaluate your project's core priorities.

- If your primary focus is cost-effective, high-volume production of complex parts: Sintering is an excellent candidate, especially for components where extreme tensile strength is not the top priority.

- If your primary focus is maximum strength and impact resistance: You should consider traditional methods like forging, extrusion, or machining from a solid billet, as they produce fully dense parts.

- If your primary focus is creating lightweight structures or unique alloys: Sintering provides powerful capabilities for controlling density and blending materials that are difficult to achieve with other methods.

By understanding both the process and its inherent trade-offs, you can confidently determine if powder metallurgy is the optimal path for manufacturing your aluminum components.

Summary Table:

| Stage | Process | Key Details |

|---|---|---|

| 1. Blending | Mixing raw materials | Combines Al powder with alloying elements & lubricant |

| 2. Compaction | Pressing into shape | High pressure (10-50 tsi) forms a 'green compact' |

| 3. Sintering | Heat treatment | Heating (550-620°C) in controlled atmosphere bonds particles |

Need to produce complex aluminum components efficiently?

Sintering is ideal for high-volume manufacturing of intricate, lightweight parts with excellent material utilization. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary to perfect your aluminum sintering process, from precise compaction tools to controlled atmosphere furnaces.

Let's discuss how our solutions can optimize your production line. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What is the microwave heating technique? A Guide to Fast, Uniform Thermal Processing

- Is sintering the same as melting? Master the Critical Thermal Process Distinction

- How much does it cost to make a lab grown diamond? The True Price of High-Tech Gem Creation

- What role does an industrial oven play in the pre-treatment of waste PCBs? Automate Thermal Disassembly with Precision

- What is sintering in ceramic? The High-Temperature Process for Creating Dense, Strong Materials

- What are the lab safety rules for heating substances? Essential Protocols to Prevent Accidents

- What is the process of pyrolysis to bio-oil? A Guide to Converting Biomass into Liquid Fuel

- What is the primary function of a vacuum pump? Remove Gas Molecules to Create a Controlled Vacuum