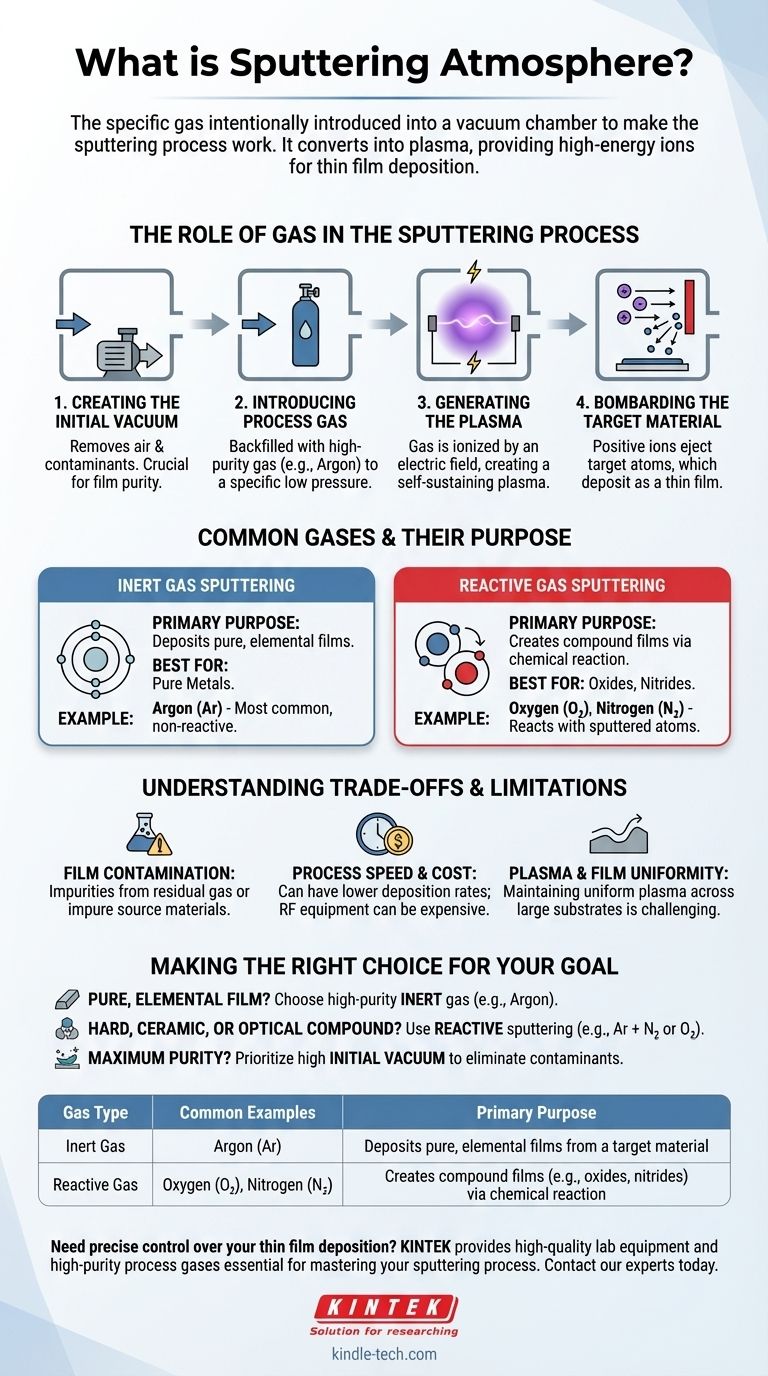

In simple terms, the sputtering atmosphere is the specific gas intentionally introduced into a vacuum chamber to make the sputtering process work. After removing unwanted air and contaminants to create a vacuum, a process gas—typically an inert gas like Argon—is backfilled into the chamber. This gas is then ionized to create a plasma, which provides the high-energy ions needed to bombard a target material and deposit a thin film onto a substrate.

The sputtering atmosphere is not a passive environment; it is the active medium that is converted into plasma. The choice of gas is a critical control parameter that directly determines the efficiency of the sputtering process and the chemical composition of the final deposited film.

The Role of Gas in the Sputtering Process

To understand the sputtering atmosphere, you must first understand its function within the deposition sequence. The process is a carefully controlled chain of events where the gas is the essential link.

Creating the Initial Vacuum

Before any deposition can occur, the chamber is pumped down to a high vacuum. This crucial first step removes ambient air, water vapor, and other particles. Failing to remove these contaminants is a primary source of impurities in the final film.

Introducing the Process Gas

Once a sufficient vacuum is achieved, the sputtering atmosphere is created by introducing a high-purity process gas. The chamber is backfilled to a specific, low pressure. This pressure is a delicate balance: too low, and there won't be enough gas atoms to sustain a stable plasma; too high, and the sputtered particles will collide too often, preventing them from reaching the substrate efficiently.

Generating the Plasma

A strong electric field is applied within the chamber. Free electrons, accelerated by this field, collide with the atoms of the process gas. These collisions are energetic enough to knock electrons off the gas atoms, creating positively charged ions and more free electrons. This cascade effect results in a self-sustaining, glowing plasma—the ionized state of the sputtering atmosphere.

Bombarding the Target Material

The positively charged ions from the plasma are accelerated by the electric field and bombard the surface of the source material, known as the "target." Each impact acts like a microscopic billiard ball collision, transferring momentum and knocking atoms loose from the target. These ejected atoms then travel through the chamber and deposit onto the substrate, building the thin film one atom at a time.

Common Gases and Their Purpose

The choice of gas is a strategic decision based on the desired outcome of the film.

Inert Gas Sputtering

The most common method uses an inert gas, with Argon (Ar) being the overwhelming favorite. It offers the best balance of atomic mass for efficient energy transfer, relatively low cost, and being chemically non-reactive. This ensures that the deposited film has the same chemical composition as the target material, creating a pure film.

Reactive Gas Sputtering

For creating compound films, a technique called reactive sputtering is used. This involves adding a "reactive" gas, such as **Nitrogen (N₂) or Oxygen (O₂) **, to the primary inert gas atmosphere. The ions of the reactive gas not only bombard the target but also chemically react with the sputtered atoms as they deposit on the substrate. This allows for the formation of materials like titanium nitride (TiN) or aluminum oxide (Al₂O₃) from a pure metal target.

Understanding the Trade-offs and Limitations

The sputtering atmosphere and the process itself have inherent limitations that must be managed.

Film Contamination

While sputtering is a very clean process, contamination is a constant concern. Impurities can arise from residual gases left after an incomplete vacuum pump-down or from the process gas itself if it is not high-purity. Contaminants can also be present in the source target material.

Process Speed and Cost

Sputtering can have a relatively low deposition rate compared to other methods like thermal evaporation. The equipment, especially the radio frequency (RF) power supplies needed for insulating materials, can also be more expensive than simple DC sources.

Plasma and Film Uniformity

On large substrates, it can be challenging to maintain a perfectly uniform plasma density across the entire target surface. This non-uniformity can lead to variations in the sputtering rate, resulting in a film that is thicker in some areas and thinner in others.

Making the Right Choice for Your Goal

The sputtering atmosphere is a fundamental parameter you control to achieve your desired film properties.

- If your primary focus is a pure, elemental film: Your best choice is a high-purity inert gas like Argon to ensure no unintended chemical reactions occur.

- If your primary focus is a hard, ceramic, or optical compound film: You will need to use reactive sputtering, carefully mixing a reactive gas like nitrogen or oxygen into the argon atmosphere.

- If your primary focus is maximum film purity and quality: Your priority must be achieving a high initial vacuum to eliminate contaminants before introducing the sputtering gas.

Ultimately, mastering the sputtering atmosphere is key to controlling the properties of your thin film.

Summary Table:

| Gas Type | Common Examples | Primary Purpose |

|---|---|---|

| Inert Gas | Argon (Ar) | Deposits pure, elemental films from a target material |

| Reactive Gas | Oxygen (O₂), Nitrogen (N₂) | Creates compound films (e.g., oxides, nitrides) via chemical reaction |

Need precise control over your thin film deposition? The sputtering atmosphere is a critical parameter for achieving the desired film properties, whether you require high-purity elemental coatings or complex compound films. KINTEK specializes in providing the high-quality lab equipment and consumables—including vacuum components and high-purity process gases—essential for mastering your sputtering process. Contact our experts today to discuss how we can support your laboratory's specific thin film needs and enhance your research and production outcomes.

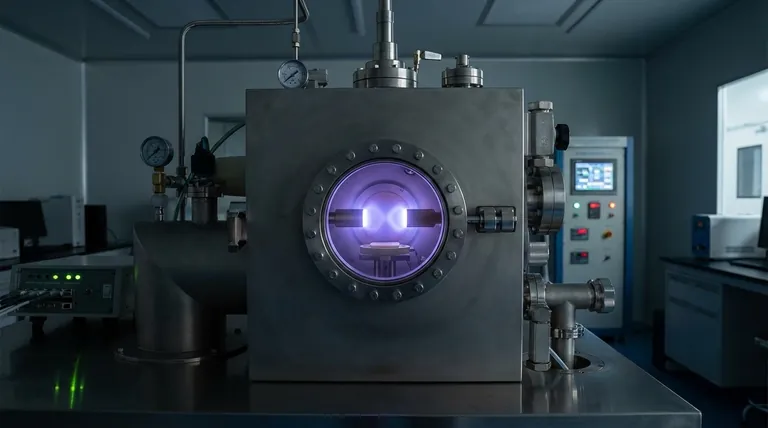

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How is graphene produced on a large scale? Scaling High-Quality Graphene with Chemical Vapor Deposition (CVD)

- What is the difference between MBE and MOCVD? Precision vs. Speed for Thin Film Growth

- What is chemical Vapour deposition in nanomaterials? A Guide to High-Purity Nanomaterial Fabrication

- What is a thin film technology? The Atomic-Scale Process Powering Modern Electronics

- What is chemical vapor deposition for CNT? The Leading Method for Scalable Carbon Nanotube Synthesis

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What is low pressure chemical Vapour deposition Lpcvd? The Key to Superior Thin Film Uniformity

- What machines make lab diamonds? Discover the HPHT and CVD Technologies Behind Lab-Grown Gems