In the simplest terms, tablet pressing is the core manufacturing process in the pharmaceutical industry for converting a powder or granulated drug formulation into a solid, oral dosage form known as a tablet. This is achieved by compacting the formulation within a die cavity using two high-pressure punches inside a machine called a tablet press.

The critical takeaway is that tablet pressing is not merely about compaction. It is a precise, multi-stage engineering process where formulation science and mechanical precision converge to ensure every single tablet has the correct dosage, stability, and physical integrity required for safe and effective medicine.

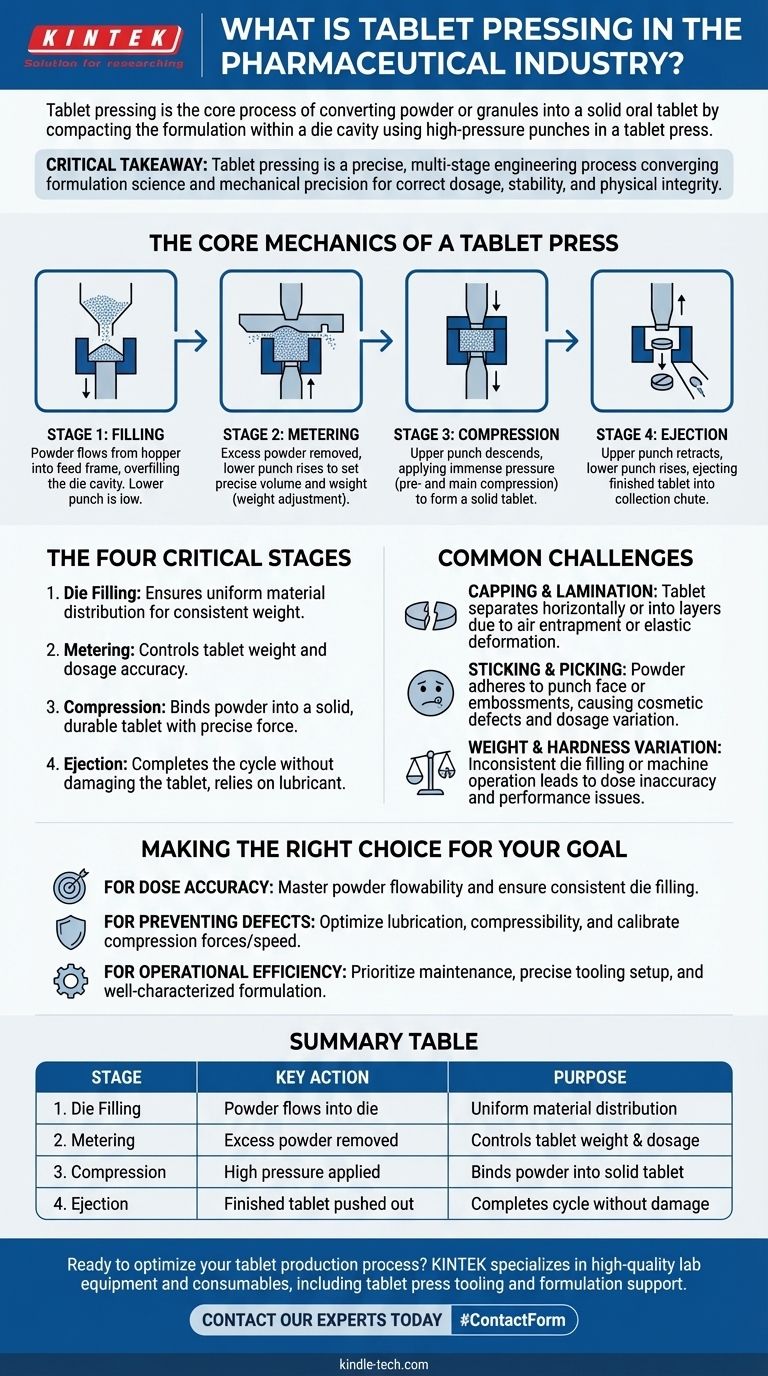

The Core Mechanics of a Tablet Press

To understand tablet pressing, you must first understand the machine that makes it possible. The process revolves around a few key components working in perfect synchronization.

The Key Players: Punches and Dies

The heart of any tablet press is the tooling: a set of upper and lower punches and a die. The die is a precision-machined cavity that defines the shape and diameter of the tablet.

The lower punch forms the bottom of the die cavity, while the upper punch descends to apply the main compressive force.

The Filling Stage

The process begins with the formulated powder, often a granulation, held in a hopper. This material flows down into a feed frame, which distributes the powder over the die table.

As the die passes under the feed frame, the lower punch is in a low position, allowing the die cavity to overfill with the powder.

The Compression Stage

Once filled, the lower punch rises to a specific height, pushing out excess powder to ensure a precise, repeatable volume—and therefore weight—in the die. This is called metering or weight adjustment.

The upper punch then descends into the die, and both punches pass between large rollers that apply immense, controlled pressure. This force compacts the powder particles, binding them together to form a solid tablet. Many modern presses use a two-step compression: a light pre-compression to remove air, followed by the main compression.

The Ejection Stage

After the main compression, the upper punch retracts. The lower punch then rises, pushing the finished tablet up and out of the die, where it is swept away into a collection chute. This cycle repeats thousands of times per minute on modern rotary presses.

From Powder to Pill: The Four Critical Stages

While the mechanics involve punches and dies, the process itself can be broken down into four distinct, critical stages that must be perfectly controlled.

1. Die Filling

This is the foundational step. The powder formulation must flow uniformly and consistently from the hopper into the die cavity. Inconsistent flow is a primary cause of tablet weight variation.

2. Metering (Weight Adjustment)

After the die is overfilled, a scraper blade removes the excess powder. The height of the lower punch at this stage is precisely set to control the volume of powder left in the die, which directly determines the tablet's weight and dosage.

3. Compression

This is where the tablet is formed. The force applied by the punches must be sufficient to create a hard, durable tablet but not so high that it causes defects like lamination or capping. This force is a critical process parameter.

4. Ejection

The final tablet must be pushed out of the die cleanly without cracking or chipping. This relies on proper press setup and, crucially, the right amount of lubricant in the powder formulation.

Understanding the Trade-offs and Common Challenges

Tablet pressing is a science, but it faces common manufacturing challenges that can compromise product quality. Understanding these is key to troubleshooting.

Capping and Lamination

Capping is when the top of the tablet separates horizontally, while lamination is when the tablet separates into two or more distinct layers. This is often caused by air being entrapped in the powder during compression or a formulation that deforms elastically instead of binding together.

Sticking and Picking

Sticking occurs when the powder formulation adheres to the flat face of the punch. Picking is a more specific version where material gets stuck in the small details of an embossed logo or letter on the punch face. Both result in cosmetically ugly tablets and can affect dosage uniformity. This is usually a sign of improper lubrication or moisture issues in the formulation.

Weight and Hardness Variation

Ensuring every tablet has the same weight and hardness is non-negotiable for dose accuracy and performance. Variation is often traced back to poor powder flowability into the die or inconsistent machine operation. A tablet that is too soft may crumble, while one that is too hard may not dissolve properly in the body.

Making the Right Choice for Your Goal

Optimizing the tablet pressing process requires balancing the formulation, machine setup, and desired outcome.

- If your primary focus is dose accuracy: Master powder flowability and ensure consistent, uniform die filling. This is the foundation of weight control.

- If your primary focus is preventing physical defects: Pay close attention to the formulation's lubrication and compressibility, and carefully calibrate compression forces and press speed.

- If your primary focus is operational efficiency: Prioritize routine machine maintenance, precise tooling setup, and a well-characterized formulation that is known to run smoothly.

Mastering the principles of tablet compression is fundamental to the consistent and reliable production of safe, effective solid oral medications.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Die Filling | Powder flows into die cavity | Ensures uniform material distribution |

| 2. Metering | Excess powder removed; lower punch adjusts height | Controls tablet weight and dosage accuracy |

| 3. Compression | Upper and lower punches apply high pressure | Binds powder into a solid, durable tablet |

| 4. Ejection | Finished tablet is pushed out of the die | Completes the cycle without damaging the tablet |

Ready to optimize your tablet production process? KINTEK specializes in high-quality lab equipment and consumables for pharmaceutical manufacturing. Our expertise in tablet press tooling and formulation support can help you achieve consistent dosage, prevent defects like capping and sticking, and improve operational efficiency. Contact our experts today to discuss how we can support your laboratory's specific tablet pressing needs.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- How fast is the rotary tablet press? Unlock Peak Production Speeds for Your Tablets

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- How does a mechanical pelletizer extend the life of calcium-based adsorbents? Maximize Your Adsorbent Durability

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- What are pill presses called? The Correct Term is Tablet Press for Pharmaceutical Manufacturing

- What is the use of tablet press? Transforming Powder into Precise, Uniform Tablets

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What is the use of a biomass pellet machine? Turn Waste into Fuel, Feed, and Bedding