The primary advantage of a three-plate mold is its ability to automatically separate the part from its plastic runner system. Unlike a simpler two-plate mold, this design uses an additional plate to create a more sophisticated material delivery system. This fundamental difference enables superior gating flexibility, improves final part quality, and dramatically reduces the need for manual post-processing.

While a two-plate mold is simpler and cheaper, a three-plate mold is chosen when the long-term benefits of automated degating, superior part cosmetics, and flexible gate locations outweigh its higher initial cost and complexity.

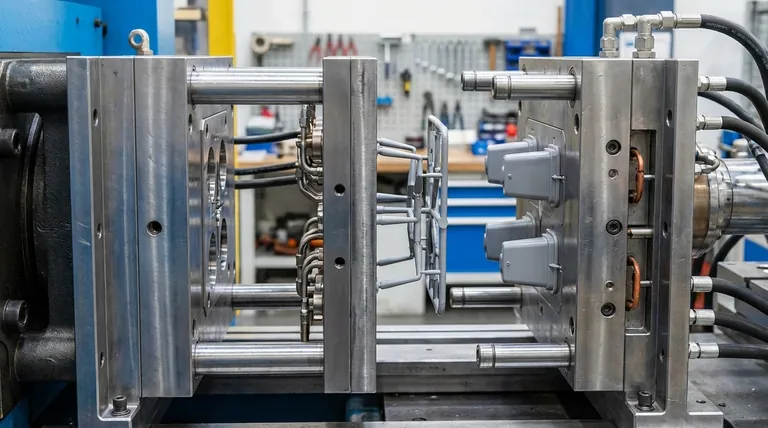

The Mechanical Difference: Two Openings, Not One

The core of the three-plate mold's advantage lies in its unique construction and opening sequence. Understanding this is key to grasping its benefits.

The Standard Two-Plate Mold

A two-plate mold is the simplest design. It consists of two halves (A and B side) that create a single split, known as the parting line. The runner system, which delivers plastic to the part cavity, is on the same parting line as the part itself. When the mold opens, the part and the runner are ejected together as a single piece.

The Advanced Three-Plate Mold

A three-plate mold introduces a third plate, the runner plate, between the main clamping plates. This creates two distinct openings:

- One opening between the runner plate and the top clamping plate to release the runner.

- A second opening at the main parting line to eject the finished part.

This two-stage opening is what allows the runner to be automatically broken off from the part during the ejection cycle.

Key Advantages of the Three-Plate System

The mechanical design of a three-plate mold directly translates into three significant manufacturing advantages.

Superior Gating Flexibility

This is arguably the most critical benefit. A three-plate mold allows for pin-point gating, where plastic is injected through a very small, precise hole. This gate can be placed almost anywhere on the part's surface, which is impossible with the edge gates typical of two-plate molds.

This flexibility optimizes resin flow, reduces internal stresses in the part, and minimizes cosmetic blemishes, leaving only a tiny, easily hidden mark.

Automatic Degating

Because the runner is on a separate plate, it is automatically snapped off and ejected separately from the part as the mold opens. This eliminates an entire post-processing step where a human operator would manually trim the runner from each part.

For high-volume production, this automation provides enormous savings in labor costs and ensures greater consistency from part to part.

Ideal for Complex and Multi-Cavity Molds

The ability to use multiple pin-point gates makes the three-plate design perfect for filling multiple part cavities simultaneously. The runner system can be designed to ensure that all cavities fill evenly and at the same pressure, which is critical for producing consistent, high-quality parts in large quantities.

Understanding the Trade-offs

The advantages of a three-plate mold do not come without costs. Objectivity requires acknowledging its downsides.

Increased Tooling Cost and Complexity

The addition of a third plate and the more complex mechanisms required for the two-stage opening make the mold significantly more expensive to design and manufacture. The initial investment can be a barrier for low-volume projects.

Potentially Longer Cycle Times

The additional movement of opening and closing two separate parting lines can add a few seconds to the overall cycle time. While automatic degating saves time on the back end, the in-mold time may be slightly longer compared to a very simple two-plate tool.

Greater Material Waste

The runner in a three-plate mold is often larger and more complex than in a two-plate design. This results in more plastic scrap material per cycle, which can be a significant cost factor, especially with expensive engineering-grade resins.

Choosing the Right Mold for Your Project

Your decision should be a strategic one based on the specific requirements of your part and production plan.

- If your primary focus is minimizing upfront tooling cost: A two-plate mold is the clear choice for simple parts, prototypes, or low-volume runs where manual degating is acceptable.

- If your primary focus is part cosmetics and design freedom: A three-plate mold is superior, as its pin-point gating allows you to hide blemishes and optimize resin flow for better part integrity.

- If your primary focus is high-volume automation and labor reduction: A three-plate mold's automatic degating provides a powerful long-term cost advantage by eliminating a manual post-processing step.

Ultimately, selecting the correct mold type is a critical engineering decision that balances upfront investment against long-term production efficiency and final part quality.

Summary Table:

| Feature | Two-Plate Mold | Three-Plate Mold |

|---|---|---|

| Gating | Edge gates only | Pin-point gates (flexible placement) |

| Degating | Manual (post-process) | Automatic (during ejection) |

| Part Quality | Potential cosmetic blemishes | Superior cosmetics, reduced stress |

| Automation | Lower (manual labor needed) | High (ideal for high-volume) |

| Cost | Lower initial cost | Higher initial cost, lower long-term labor cost |

| Material Waste | Less runner waste | More runner waste |

Optimize your injection molding process with the right tooling expertise.

At KINTEK, we specialize in providing laboratory equipment and consumables, including solutions for R&D and prototyping in materials science. Whether you're developing new plastic parts or optimizing production, understanding the right mold design is crucial for efficiency and quality.

Let our experts help you evaluate your project needs and select the best approach for superior results. Contact us today to discuss how we can support your laboratory and production goals!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Cylindrical Press Mold with Scale for Lab

- Special Heat Press Mold for Lab Use

People Also Ask

- What is the physical role of graphite molds in vacuum hot pressing? Optimize Cu-Al2O3 Composite Densification

- What are the primary functions of graphite molds in NiCr powder metallurgy? Optimize Your Composite Material Density

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture