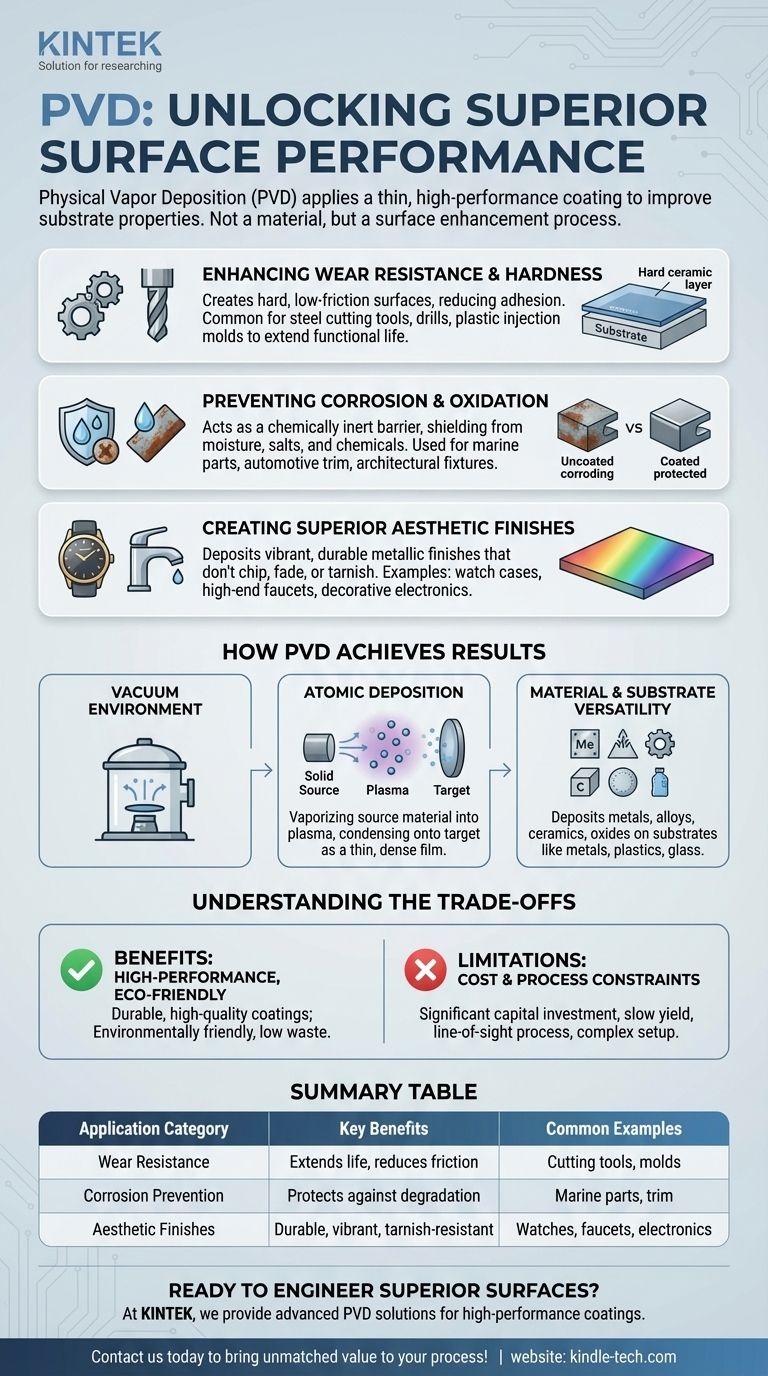

In short, Physical Vapor Deposition (PVD) is used to apply a thin, high-performance coating onto a surface to dramatically improve its properties. This process is widely applied to enhance the wear resistance of industrial cutting tools, provide durable and decorative finishes on consumer products, and improve the corrosion resistance of components in demanding environments.

PVD is not a material, but a surface enhancement process. It allows you to give an inexpensive or lightweight base material the superior surface characteristics—like hardness, wear resistance, and corrosion resistance—of a far more exotic material, without changing the core component.

What Problems Does PVD Solve?

PVD is fundamentally a problem-solving technology. It is selected when the surface of a component needs capabilities that the underlying base material cannot provide on its own.

Enhancing Wear Resistance and Hardness

The most common industrial application of PVD is creating an exceptionally hard, low-friction surface. This is critical for items that experience intense friction and wear.

A thin ceramic layer, often less than 4 micrometers thick, is deposited onto the substrate. This drastically reduces the risk of adhesion and sticking, extending the functional life of the tool.

This is standard practice for steel cutting tools, drills, and bits used in metalworking, as well as for plastic injection molds where smooth release and durability are essential.

Preventing Corrosion and Oxidation

Many materials, while strong or lightweight, are susceptible to environmental degradation. PVD coatings act as a chemically inert barrier.

This protective layer shields the substrate from moisture, salts, and chemicals that cause corrosion, tarnishing, or fading. The coating itself is exceptionally stable and durable.

This is vital for parts used in marine applications, automotive trim, and architectural fixtures where long-term appearance and integrity are required.

Creating Superior Aesthetic Finishes

PVD enables the deposition of a wide array of vibrant, metallic finishes that are significantly more durable than traditional plating or painting.

These coatings bond to the substrate at an atomic level, meaning they will not chip, fade, or tarnish over time. This provides a premium look and feel that lasts.

Common examples include watch cases, high-end faucets, door hardware, and decorative elements on consumer electronics.

How PVD Achieves These Results

The versatility of PVD comes from its unique deposition method, which operates in a high-vacuum environment.

A Process of Atomic Deposition

PVD works by vaporizing a solid source material (like titanium or chromium) into a plasma of atoms or molecules. Common methods include sputtering and thermal evaporation.

These vaporized particles then travel through the vacuum chamber and condense onto the target object, forming a very thin, dense, and highly-adherent film.

Unmatched Material Versatility

The process can deposit a vast range of materials, including pure metals, alloys, ceramics (nitrides, carbides), and oxides.

Because PVD is a low-temperature process—sometimes even performed at room temperature—it can be used to coat substrates that cannot withstand heat. This includes plastics, glass, and ceramics, in addition to all types of metals.

Thin, Precise Layers

PVD allows for extreme control over the coating thickness, enabling the deposition of layers down to just several tens of nanometers. This precision is essential for applications in optics and semiconductors.

Understanding the Trade-offs

While powerful, PVD is not the right solution for every application. Acknowledging its limitations is key to using it effectively.

The Benefit: High-Performance, Eco-Friendly Coatings

The primary advantage is a high-quality, durable coating that vastly improves a component's surface properties. The process is also environmentally friendly, generating very little waste and using no hazardous chemicals.

The Limitation: Cost and Process Constraints

PVD equipment represents a significant capital investment. The process itself can have a slow rate of yield compared to other coating methods like electroplating.

Furthermore, it is a line-of-sight process, making it difficult to coat complex internal geometries. It also requires a reliable vacuum and cooling system, adding to its operational complexity and cost.

Making the Right Choice for Your Application

Use PVD when surface properties are a critical design constraint and the benefits of the enhanced performance justify the investment.

- If your primary focus is extending tool life and performance: PVD is the industry standard for creating hard, low-friction surfaces on cutting tools and molds.

- If your primary focus is premium aesthetics and durability: PVD provides a durable, tarnish-resistant decorative finish on consumer products that far surpasses traditional plating.

- If your primary focus is protecting sensitive components: PVD is an excellent choice for applying highly corrosion-resistant and inert coatings on everything from medical parts to aerospace components.

- If your primary focus is coating low-cost bulk items: Carefully evaluate the economics, as the cost and slower process speed of PVD may not be suitable for all high-volume, low-margin parts.

Ultimately, PVD empowers you to engineer the surface of a component independently of its bulk material, unlocking a new level of product performance and design.

Summary Table:

| Application Category | Key Benefits | Common Examples |

|---|---|---|

| Wear Resistance | Extends tool life, reduces friction | Cutting tools, injection molds |

| Corrosion Prevention | Protects against tarnishing and degradation | Marine parts, automotive trim |

| Aesthetic Finishes | Durable, vibrant, and tarnish-resistant | Watches, faucets, electronics |

Ready to engineer superior surface properties for your components?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including PVD solutions, to help you achieve high-performance coatings that enhance durability, prevent corrosion, and create lasting aesthetic finishes. Whether you're working on industrial tools, consumer products, or sensitive components, our expertise ensures you get the right coating technology for your needs.

Contact us today to discuss how our PVD solutions can bring unmatched value to your laboratory or production process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications