The best crucible for melting is not a single product, but a choice dictated by the material you are melting, the maximum temperature you need to reach, and your heating method. While common options include graphite and various ceramics like fused silica (quartz), selecting the wrong one can lead to contamination, equipment failure, or a ruined melt.

The selection of a crucible is a balancing act. Your goal is to choose a material that can withstand your target temperature without cracking from thermal shock, and critically, that will not chemically react with or contaminate the material you are melting.

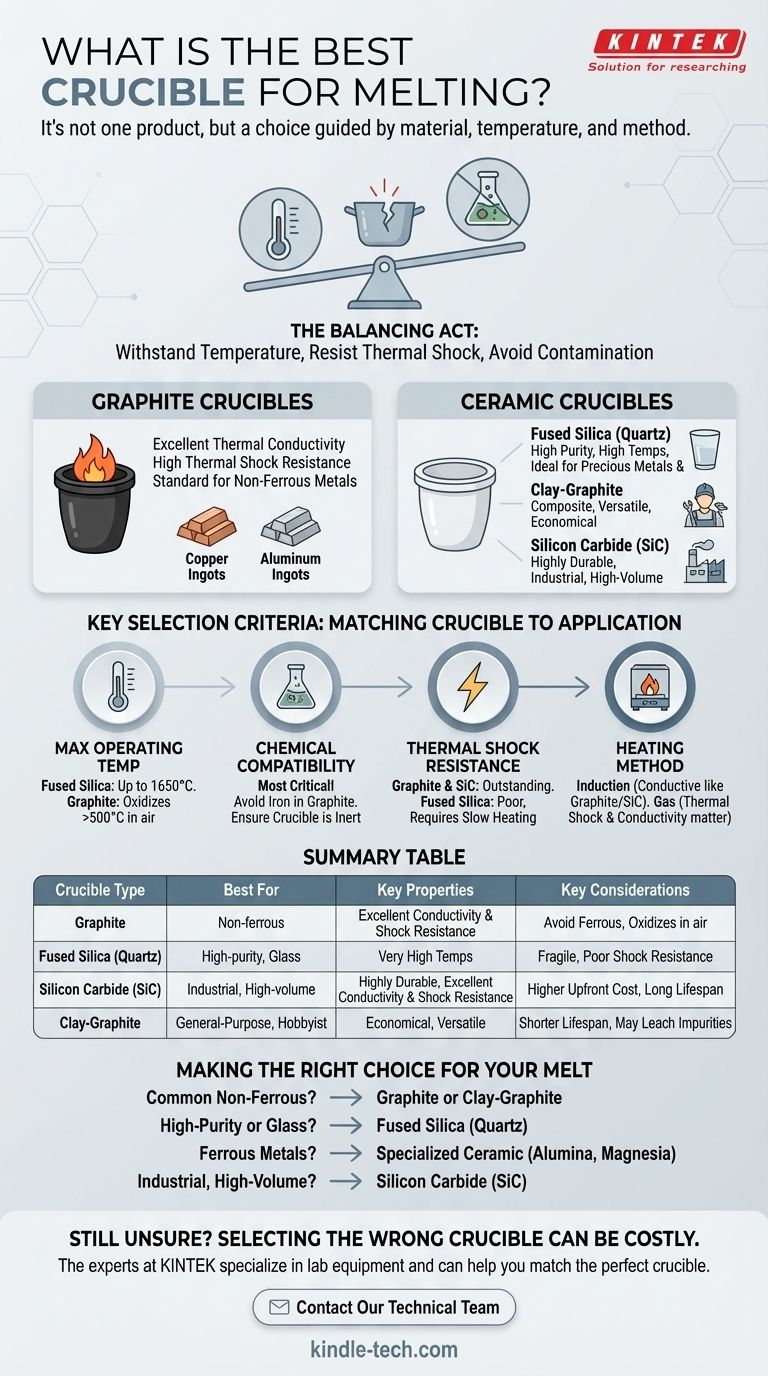

The Two Primary Categories of Crucibles

To make the right choice, you first need to understand the fundamental properties of the main crucible families. Each is designed for a different set of conditions.

Graphite Crucibles

Graphite crucibles are known for their excellent thermal conductivity, meaning they transfer heat to your material very efficiently. This makes for faster melt times.

They are also highly resistant to thermal shock, so they are less likely to crack from rapid heating or cooling. They are the standard choice for most non-ferrous metals.

Ceramic Crucibles

This is a broad category that includes materials like fused silica (quartz), clay-graphite, and silicon carbide.

- Fused Silica (Quartz): These are extremely pure and can withstand very high temperatures. They are ideal for high-purity melts or materials that would react with carbon, such as certain precious metal alloys or glass.

- Clay-Graphite: These are composite crucibles that blend the thermal conductivity of graphite with the durability of clay binders. They are a versatile and economical choice for hobbyists and general-purpose melting.

- Silicon Carbide (SiC): These are highly durable, long-lasting crucibles with excellent thermal conductivity. They are a top choice for industrial and high-volume applications due to their resistance to wear and chemical attack.

Key Selection Criteria: Matching Crucible to Application

The "best" crucible is the one whose properties are correctly aligned with your specific job. Consider these four factors above all else.

Maximum Operating Temperature

Every crucible has a temperature limit. Fused silica can handle extremely high heat (up to 1650°C / 3000°F), but graphite will begin to oxidize (burn away) in an oxygen atmosphere above 500°C (932°F), requiring a vacuum or inert atmosphere for high-temperature work.

Chemical Compatibility

This is the most critical factor for melt quality. The crucible should be as inert as possible to the material you are melting (your "charge").

For example, melting iron or steel in a pure graphite crucible is a mistake. The molten iron will readily absorb carbon from the crucible walls, changing its properties and turning it into a high-carbon steel or cast iron. For this, a ceramic crucible is necessary.

Thermal Shock Resistance

Thermal shock is the stress a material endures when its temperature changes rapidly. Materials with poor thermal shock resistance, like fused silica, will crack if heated or cooled too quickly.

Graphite and silicon carbide have outstanding resistance to thermal shock, making them more forgiving and suitable for faster process cycles.

Heating Method

Your furnace type matters. Induction furnaces require a conductive crucible (like graphite or silicon carbide) to work efficiently, as the furnace induces an electric current directly in the crucible wall to generate heat.

In a gas-fired furnace, thermal shock resistance and overall conductivity are more important.

Understanding the Trade-offs

There is no perfect material. Every choice involves compromising on cost, durability, or performance.

Purity vs. Durability

Fused silica offers exceptional purity but is mechanically fragile and very susceptible to thermal shock. A silicon carbide crucible is incredibly durable but may not be suitable for applications where even minor silicon contamination is a concern.

Cost vs. Lifespan

A cheap clay-graphite crucible may only last for a handful of melts. An expensive silicon carbide crucible, if treated properly, can last for hundreds. You must balance the upfront cost against the cost-per-melt over the crucible's entire lifespan.

The Risk of Contamination

Contamination is the silent killer of good results. Using a graphite crucible for ferrous metals introduces carbon. Using a low-quality clay crucible can leach impurities into your melt. Always verify that your crucible material is inert to your specific charge and any fluxes you plan to use.

Making the Right Choice for Your Melt

To select the correct crucible, align your primary goal with the material best suited for that task.

- If your primary focus is melting common non-ferrous metals (like aluminum, brass, or gold): Use a graphite or clay-graphite crucible for its excellent thermal performance and durability.

- If your primary focus is high-purity melts or melting glass: Use a fused silica (quartz) crucible, but be sure to heat and cool it very slowly to prevent cracking.

- If your primary focus is melting ferrous metals (like iron or steel): Avoid pure graphite and use a specialized ceramic crucible (like alumina or magnesia) to prevent carbon contamination.

- If your primary focus is industrial, high-volume production: Invest in a silicon carbide (SiC) crucible for its superior lifespan, durability, and thermal efficiency.

By understanding these material properties, you can move beyond asking "what is best" and confidently select what is right for your work.

Summary Table:

| Crucible Type | Best For | Key Properties | Key Considerations |

|---|---|---|---|

| Graphite | Non-ferrous metals (Al, Brass, Gold) | Excellent thermal conductivity, high thermal shock resistance | Avoid with ferrous metals (causes carbon contamination); oxidizes above 500°C in air |

| Fused Silica (Quartz) | High-purity melts, glass | Extremely pure, withstands very high temps (up to 1650°C) | Fragile, poor thermal shock resistance (heat/cool slowly) |

| Silicon Carbide (SiC) | Industrial, high-volume production | Highly durable, excellent thermal conductivity & shock resistance | Higher upfront cost, long lifespan |

| Clay-Graphite | General-purpose, hobbyist melting | Economical, versatile blend of properties | Shorter lifespan, may leach impurities |

Still Unsure Which Crucible is Right for Your Application?

Selecting the wrong crucible can lead to costly contamination, equipment failure, and ruined batches. The experts at KINTEK specialize in lab equipment and consumables, including a full range of high-performance crucibles for every melting need—from precious metals and glass to industrial-scale production.

We can help you:

- Match the perfect crucible material to your specific metal, alloy, or glass.

- Ensure compatibility with your furnace type (induction, gas, electric) and temperature requirements.

- Maximize your crucible's lifespan and performance with proper selection and handling advice.

Don't gamble with your melt. Contact our technical team today for a personalized recommendation and get the right crucible for the job.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What is the purpose of using alumina crucibles as liners in autoclaves? Ensure Purity in High-Pressure Static Tests

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- What temperature can alumina crucible withstand? A Guide to High-Temperature Stability and Safety

- What temperature is an Al2O3 crucible? Key Factors for High-Temperature Success Up to 1700°C

- Why Use Alumina Crucibles for TGA of Bicyclic Carbonates? Ensure Data Purity & Chemical Inertness