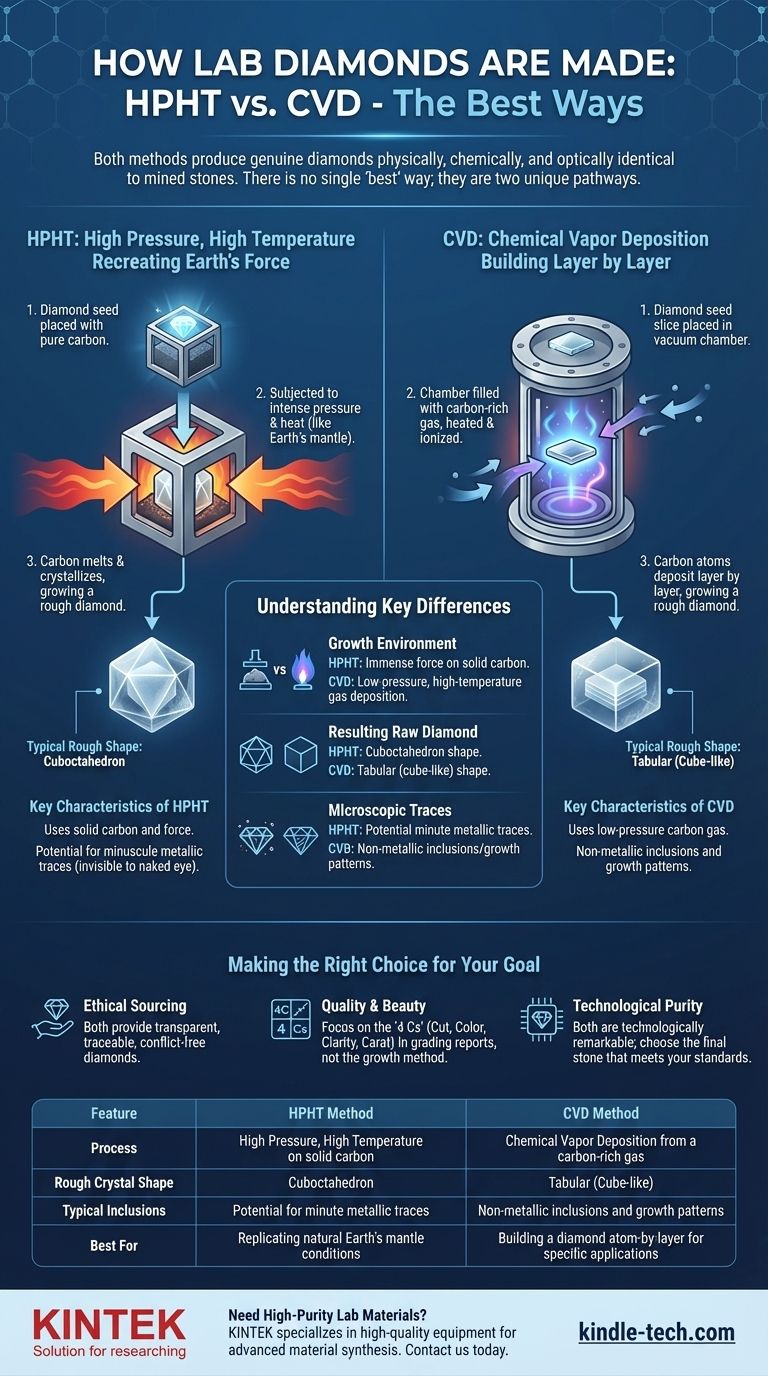

There is no single "best" way to make lab diamonds. Instead, two highly advanced and distinct methods exist: High Pressure, High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both processes create diamonds that are physically, chemically, and optically identical to those mined from the Earth. The "best" method is a matter of understanding their fundamental differences, as each produces a genuine diamond through a unique pathway.

The question is not which method creates a "better" or "more real" diamond—both produce authentic diamonds. The critical distinction lies in their growth process, which results in different microscopic characteristics and raw crystal shapes.

The Two Paths to a Lab-Grown Diamond

At their core, both HPHT and CVD methods aim to replicate the natural diamond-growing process. One mimics the brute force of the Earth's mantle, while the other mimics the formation of crystals from a gas.

HPHT: Recreating the Earth's Force

HPHT stands for High Pressure, High Temperature. As the original method developed in the 1950s, it directly simulates the intense conditions deep within the Earth that create natural diamonds.

The process begins by placing a tiny, pre-existing diamond crystal, known as a seed, into a chamber with pure carbon.

This chamber is then subjected to immense pressure and extreme heat. The intense conditions cause the carbon to melt and crystallize around the diamond seed, growing a new, larger rough diamond.

CVD: Building a Diamond Layer by Layer

CVD, or Chemical Vapor Deposition, is a newer technique that builds a diamond atom by atom. It can be thought of as a highly controlled, high-tech form of crystal growth.

This process starts with a thin slice of a diamond seed placed inside a vacuum chamber.

The chamber is filled with a carbon-rich gas and heated to extreme temperatures. The gas ionizes, breaking down into its constituent carbon atoms, which then "stick" to the diamond seed slice, building up successive layers and growing into a complete diamond crystal over several weeks.

Understanding the Key Differences

While the end product is chemically diamond in both cases, the journey from carbon to crystal leaves subtle clues that distinguish the two methods.

The Growth Environment

The fundamental difference is the state of the carbon. HPHT uses immense force to press solid carbon into a crystal. CVD uses a low-pressure, high-temperature gas to deposit carbon layers.

This distinction is the primary reason for all other differences between the two types of lab-grown diamonds.

The Resulting Raw Diamond

The growth environment directly influences the shape of the rough diamond.

HPHT diamonds typically grow in a cuboctahedron shape, with faces in multiple directions. CVD diamonds grow in a flatter, tabular (cube-like) shape, as the carbon deposits onto the seed slice.

Potential for Microscopic Traces

Each method can leave behind unique microscopic characteristics related to its process.

Because the HPHT process often uses a metal cube and catalyst, it is possible for some HPHT diamonds to have minuscule metallic traces within their structure. These are almost always invisible to the naked eye and do not impact the diamond's beauty or durability.

CVD growth, on the other hand, occurs in a different environment, so its internal growth patterns and any potential inclusions will be non-metallic in nature. Advanced gemological equipment can identify these distinct growth markers to determine a diamond's origin.

Making the Right Choice for Your Goal

Ultimately, the manufacturing method is secondary to the quality of the final, polished gem. A high-quality grading report from a reputable lab (like GIA or IGI) is far more important than whether the diamond is HPHT or CVD.

- If your primary focus is ethical sourcing: Both methods produce genuine, conflict-free diamonds with a transparent and traceable origin.

- If your primary focus is quality and beauty: Judge the diamond on its "4 Cs" (cut, color, clarity, and carat) as detailed in its grading report, not its growth method.

- If your primary focus is technological purity: Understand that both methods are technologically remarkable, and the "best" is the one that yields a final stone meeting your specific standards for clarity and color.

Choose the diamond, not the process, and you will make an excellent decision.

Summary Table:

| Feature | HPHT Method | CVD Method |

|---|---|---|

| Process | High Pressure, High Temperature on solid carbon | Chemical Vapor Deposition from a carbon-rich gas |

| Rough Crystal Shape | Cuboctahedron | Tabular (Cube-like) |

| Typical Inclusions | Potential for minute metallic traces | Non-metallic inclusions and growth patterns |

| Best For | Replicating natural Earth's mantle conditions | Building a diamond atom-by-layer for specific applications |

Need High-Purity Lab Materials for Your Research or Production?

Whether you are developing CVD processes or working with high-pressure systems, the right equipment is crucial for success. KINTEK specializes in providing high-quality lab equipment and consumables tailored to advanced material synthesis, including diamond growth.

Contact our experts today to discuss how our solutions can enhance the precision, efficiency, and yield of your lab-grown diamond projects.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is the difference between pyrolysis? Slow vs. Fast vs. Flash Explained

- How is an electric constant temperature drying oven utilized in the curing process of Pd/G-SS electrodes?

- What are the different types of reactors used in pyrolysis? Find the Best Fit for Your Feedstock and Goals

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- What is the vacuum sublimation method? A Guide to High-Purity Material Purification

- What criteria do companies use when choosing manufacturers for lab equipment? Ensure a Strategic Investment

- How thick is gold sputtering? Achieve Precise Coatings from Ångstroms to Microns

- What are sintered products used for? From Gears to Medical Implants, Discover Their Versatility