Parylene chemical vapor deposition is a unique vacuum-based process used to apply an ultra-thin, perfectly uniform polymer coating onto a substrate. Unlike liquid coatings, this method involves converting a solid raw material, called a dimer, into a gas. In a vacuum, this gas polymerizes directly onto all exposed surfaces of an object at room temperature, forming a protective film.

The core principle is that parylene isn't applied as a liquid but "grows" on the component's surface. This gas-phase polymerization allows it to create a completely conformal and pinhole-free plastic coating without the thermal or mechanical stress of other methods.

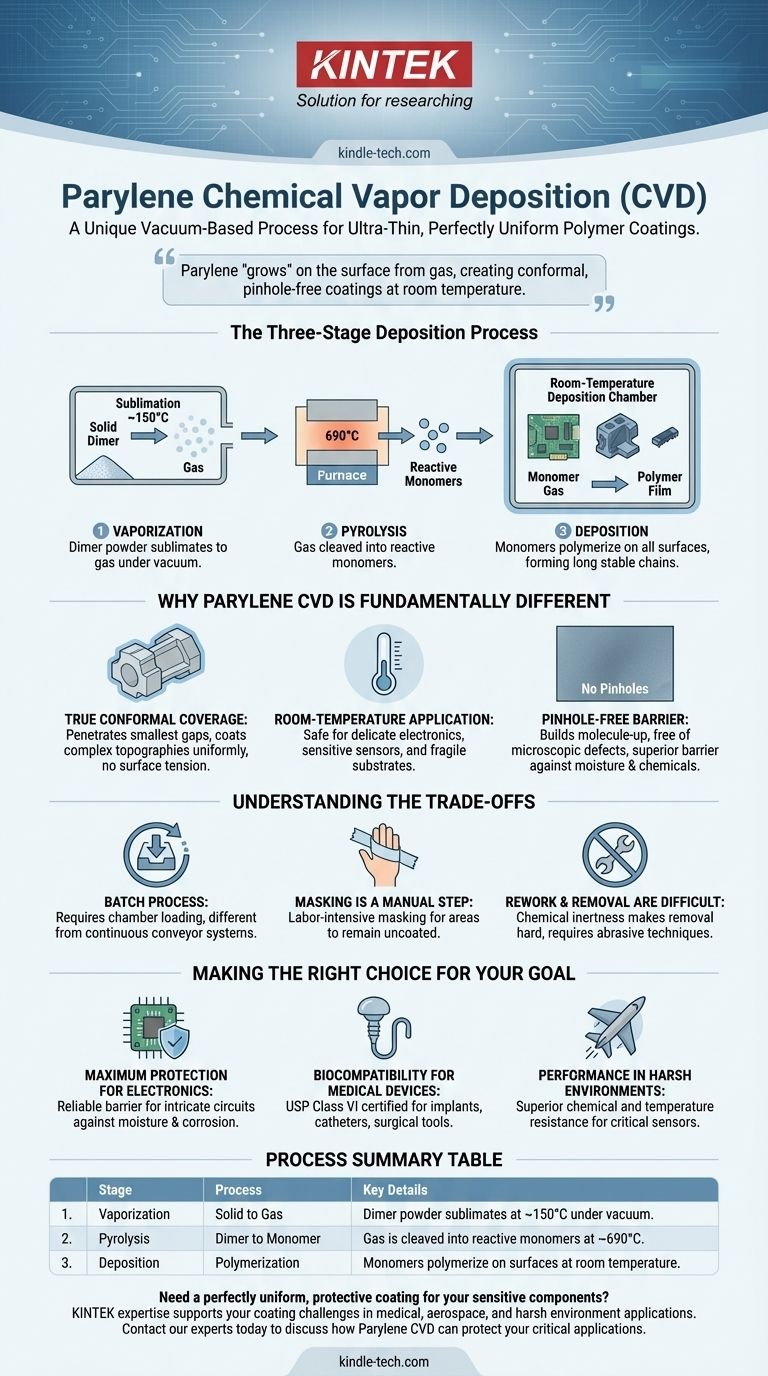

The Three-Stage Deposition Process

Parylene CVD is a highly controlled process that occurs entirely within a connected vacuum system. It consists of three distinct stages that transform a solid powder into a final polymer film.

Stage 1: Vaporization

The process begins with the raw material, a crystalline solid known as di-p-xylylene (or simply "dimer"), placed in a vaporizer chamber. The chamber is heated to approximately 150 °C under a vacuum. This causes the solid dimer to sublimate, turning directly into a gas.

Stage 2: Pyrolysis

This dimer gas then flows into a second, much hotter furnace heated to around 690 °C. This intense heat cleaves the dimer molecule into two highly reactive "monomer" molecules. This step is the critical chemical transformation that prepares the material for polymerization.

Stage 3: Deposition

The reactive monomer gas enters the final room-temperature deposition chamber, which contains the parts to be coated. As the gas molecules land on any surface inside the chamber, they spontaneously link together, or polymerize, forming a long, stable polymer chain. This film grows one molecule at a time, resulting in a coating that is exceptionally uniform across all surfaces, including sharp edges, crevices, and even inside small bores.

Why This Process is Fundamentally Different

The CVD method gives parylene properties that are unattainable with conventional liquid coatings like acrylic, epoxy, or urethane.

True Conformal Coverage

Because the coating is formed from a gas, it has no surface tension. It can penetrate the smallest gaps and coat complex 3D topographies without thinning on sharp corners or pooling in low spots, a common failure point for sprayed or dipped coatings.

Room-Temperature Application

The actual coating deposition occurs at ambient temperature. This means delicate electronic components, sensitive sensors, and fragile substrates can be coated without any risk of thermal damage or stress.

Pinhole-Free Barrier

The polymerization process builds the coating from the molecule up. This method results in a plastic film with supreme barrier properties, free of the microscopic pinholes that can plague liquid coatings and allow moisture or chemicals to attack the underlying component.

Understanding the Trade-offs

While powerful, the parylene CVD process has specific operational characteristics that must be considered.

It Is a Batch Process

Parts must be loaded into a vacuum chamber for each coating run. This is different from a continuous conveyor-based process like spraying, which can impact throughput and cost for very high-volume manufacturing.

Masking is a Manual Step

Since the parylene gas will coat everything it touches, any areas that must remain uncoated (like connector pins or contact pads) need to be manually masked before being placed in the chamber. This adds labor and time to the overall process.

Rework and Removal are Difficult

The same chemical inertness that makes parylene an excellent protective barrier also makes it very difficult to remove. Reworking a coated board typically requires specialized abrasive techniques, as chemical stripping is often ineffective.

Making the Right Choice for Your Goal

Selecting parylene is a decision based on performance requirements. Its unique application method makes it an ideal solution for specific, high-stakes challenges.

- If your primary focus is maximum protection for complex electronics: The perfectly conformal and pinhole-free nature of parylene provides the most reliable barrier against moisture and corrosion for intricate circuit boards.

- If your primary focus is biocompatibility for medical devices: Parylene is USP Class VI certified and has a long history of use for implants, catheters, and surgical tools due to its inert and protective qualities.

- If your primary focus is performance in harsh environments: The chemical and temperature resistance of parylene makes it a superior choice for aerospace, defense, and industrial sensors that must function without fail.

By understanding the fundamentals of the parylene CVD process, you can leverage its distinct advantages for your most critical applications.

Summary Table:

| Stage | Process | Key Details |

|---|---|---|

| 1. Vaporization | Solid to Gas | Dimer powder sublimates at ~150°C under vacuum. |

| 2. Pyrolysis | Dimer to Monomer | Gas is cleaved into reactive monomers at ~690°C. |

| 3. Deposition | Polymerization | Monomers polymerize on surfaces at room temperature. |

Need a perfectly uniform, protective coating for your sensitive components?

The Parylene CVD process offers unparalleled conformal coverage and pinhole-free barrier properties that liquid coatings cannot match. If you are developing medical devices, aerospace electronics, or any product requiring maximum reliability in harsh environments, KINTEK's expertise in lab equipment and consumables can support your coating challenges.

Contact our experts today to discuss how Parylene CVD can protect your critical applications.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application