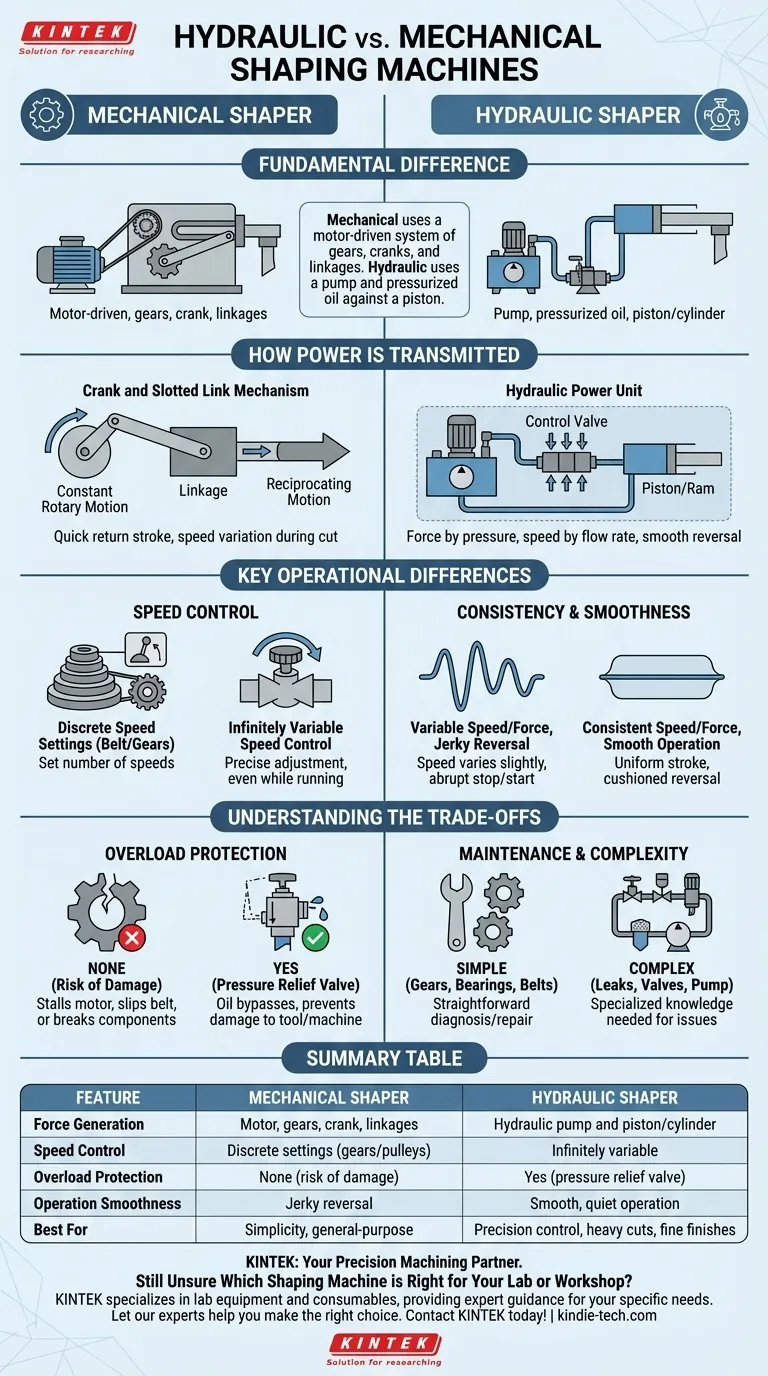

The fundamental difference lies in how each machine generates force. A mechanical shaping machine uses a motor-driven system of gears, cranks, and linkages to move the cutting ram back and forth. In contrast, a hydraulic shaping machine uses a pump to move pressurized oil against a piston inside a cylinder, which in turn drives the ram.

While both machines cut flat surfaces, the choice between them is a classic engineering trade-off. Mechanical shapers offer simplicity and robust efficiency, whereas hydraulic shapers provide superior control, smoother operation, and inherent overload protection.

How Power is Transmitted to the Ram

The drive mechanism is the defining characteristic of each machine and dictates its performance, feel, and capabilities.

The Mechanical Shaper: A System of Levers and Gears

A mechanical shaper uses a crank and slotted link mechanism (or a similar linkage). This clever geometric arrangement converts the constant rotary motion of the motor into the reciprocating (back-and-forth) motion of the ram.

A key feature of this design is the quick return stroke. The linkage is designed so the ram moves slower during the forward cutting stroke and significantly faster on the backward return stroke, minimizing non-productive time.

The Hydraulic Shaper: The Power of Pressurized Fluid

A hydraulic shaper employs a hydraulic power unit. A pump forces oil into a cylinder, pushing a piston that is connected to the ram.

To reverse direction, a control valve simply redirects the flow of oil to the opposite side of the piston. The force is determined by the system's pressure, and the speed is determined by the fluid's flow rate.

Key Operational Differences

The drive system directly impacts how the machine is controlled and how it behaves under load.

Speed Control: Discrete vs. Infinite

On a mechanical shaper, cutting speed is typically adjusted by changing belt positions on step pulleys or by shifting gears in a gearbox. This gives you a set number of discrete speed settings.

A hydraulic shaper offers infinitely variable speed control. By simply turning a flow control valve, the operator can precisely adjust the ram's speed anywhere within its range, even while the machine is running.

Consistency of Force and Speed

A hydraulic system delivers a very consistent force and speed throughout the entire cutting stroke. This is ideal for achieving a uniform surface finish, especially on long workpieces.

While effective, the speed of a mechanical shaper's ram varies slightly throughout the cut due to the geometry of the linkage.

Smoothness of Operation

The reversal of the ram on a hydraulic shaper is exceptionally smooth. The cushioning effect of the oil absorbs the shock, resulting in less vibration and quieter operation.

Mechanical shapers have a more abrupt and "jerky" reversal at each end of the stroke, which can transmit shock through the machine and workpiece.

Understanding the Trade-offs

Neither design is universally superior; each has distinct advantages and disadvantages that make it suitable for different applications.

Overload Protection: A Critical Safety Distinction

This is a major advantage for hydraulic systems. If the cutting tool encounters a hard spot or the cut is too deep, a pressure relief valve opens, allowing the oil to bypass the cylinder. This stops the ram's movement and prevents damage to the tool, workpiece, or machine.

A mechanical shaper has no such safety net. In an overload situation, it will either stall the motor, slip a belt, or, in a worst-case scenario, break the cutting tool or a machine component.

Maintenance and Complexity

Mechanical shapers are relatively simple. Problems usually involve worn gears, bearings, or belts, which are straightforward for a machinist to diagnose and repair.

Hydraulic systems can be more complex to troubleshoot. Issues like fluid leaks, pump failures, valve malfunctions, or contaminated oil often require specialized knowledge.

Machine Power

Hydraulic systems can generate enormous forces in a compact space. For this reason, very large and powerful shaping and planing machines are almost exclusively hydraulic.

Making the Right Choice for Your Application

Selecting the correct machine depends entirely on your operational priorities and the nature of the work you perform.

- If your primary focus is simplicity and general-purpose work: A mechanical shaper is a robust, reliable, and easy-to-maintain choice for a job shop or hobbyist.

- If your primary focus is precision control and heavy cuts: A hydraulic shaper offers superior control over cutting speed and built-in protection against overloads, making it ideal for production or demanding tasks.

- If your primary focus is achieving the best possible surface finish: The hydraulic shaper's smooth, consistent stroke provides a distinct advantage in creating uniform, high-quality surfaces.

Ultimately, understanding how each machine generates and controls its power is the key to selecting the right tool for your specific machining goals.

Summary Table:

| Feature | Mechanical Shaper | Hydraulic Shaper |

|---|---|---|

| Force Generation | Motor, gears, crank, and linkages | Hydraulic pump and piston/cylinder |

| Speed Control | Discrete settings (gears/pulleys) | Infinitely variable |

| Overload Protection | None (risk of damage) | Yes (pressure relief valve) |

| Operation Smoothness | Jerky reversal | Smooth, quiet operation |

| Best For | Simplicity, general-purpose work | Precision control, heavy cuts, fine finishes |

Still Unsure Which Shaping Machine is Right for Your Lab or Workshop?

Choosing between a mechanical and hydraulic shaper is critical for achieving your precision machining goals. KINTEK specializes in lab equipment and consumables, providing expert guidance to help you select the ideal machinery for your specific needs—whether you prioritize robust simplicity or advanced control.

Let our experts help you make the right choice. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Small Injection Molding Machine for Lab Use

People Also Ask

- Why is KBr pellet used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is another name for a hydraulic press? The Bramah Press and Its Powerful Principle

- How does a laboratory hydraulic press contribute to g-CNT electrode preparation? Mastering Material Densification

- What is KBr pellet technique? Master Solid Sample FTIR Analysis with Clear Pellets

- What is the function of a laboratory hydraulic press in PHA film production? Perfecting Bio-Packaging Standards

- What are the factors that determine the quality of pellets? Maximize Heat and Minimize Maintenance

- What should the mortar and pestle be cleaned with before preparing a KBr pellet for IR? Ensure Accurate IR Spectroscopy Results

- How much force can a hydraulic cylinder produce? Unlock the Power of Hydraulic Force Calculations