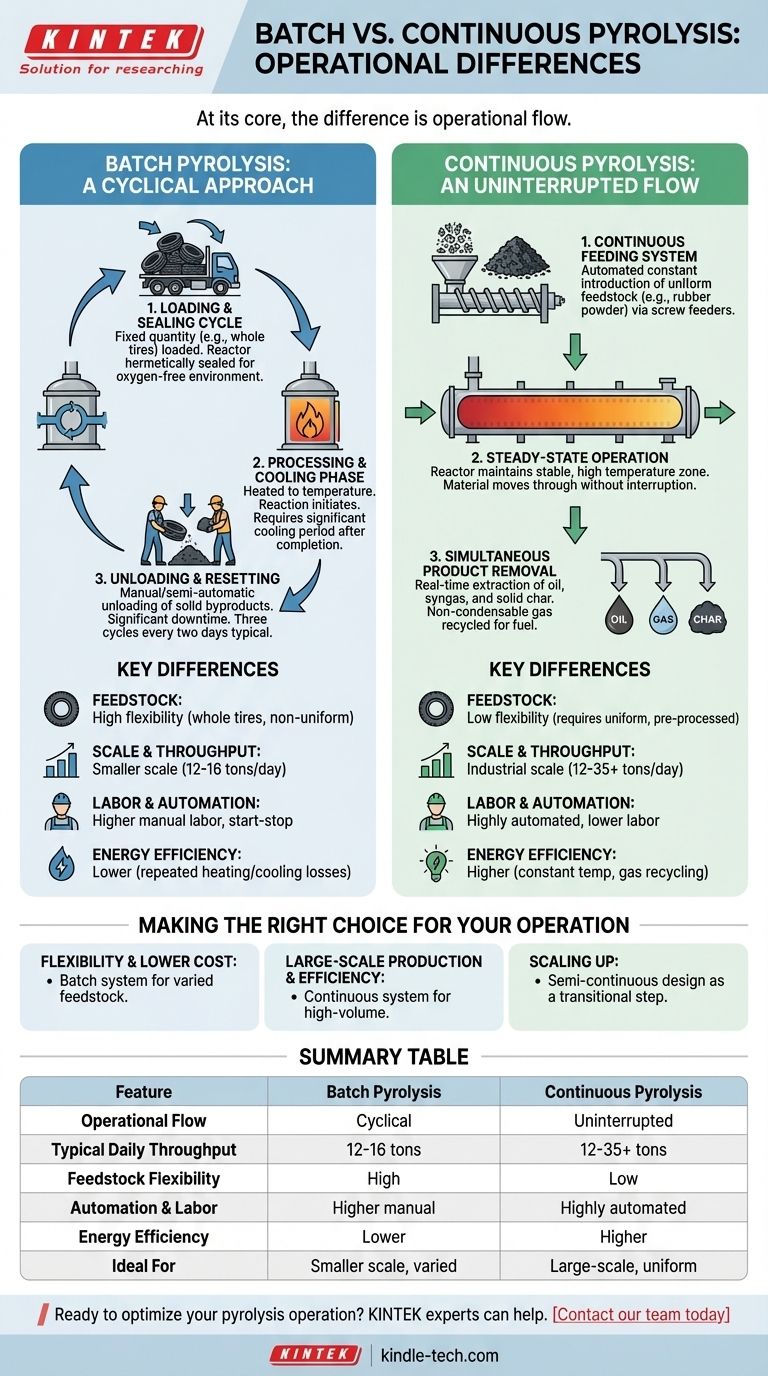

At its core, the difference is operational flow. Batch pyrolysis is a cyclical process where a fixed amount of material is loaded, heated, processed, and then removed before the next cycle can begin. In contrast, continuous pyrolysis operates as an uninterrupted system, constantly feeding raw material in and discharging finished products simultaneously.

The choice between batch and continuous pyrolysis is not about which is "better," but which aligns with your operational scale, feedstock consistency, and investment level. Batch systems offer flexibility for smaller or varied inputs, while continuous systems demand high volume and uniformity to achieve superior efficiency.

The Batch Pyrolysis Process: A Cyclical Approach

The Loading and Sealing Cycle

In a batch system, the process begins by loading a fixed quantity of feedstock, such as whole tires, into the reactor. Once full, the reactor is hermetically sealed to create an oxygen-free environment.

The Processing and Cooling Phase

The sealed reactor is heated to the required temperature, initiating the pyrolysis reaction. After the reaction is complete, the entire system must undergo a lengthy cooling period before it is safe to open.

Unloading and Resetting

Once cooled, operators manually or semi-automatically unload the solid byproducts (like carbon black and steel wire). This downtime for cooling and unloading is significant, with a typical plant running three cycles every two days.

The Continuous Pyrolysis Process: An Uninterrupted Flow

Continuous Feeding System

Continuous plants use automated systems, like screw feeders, to constantly introduce pre-processed feedstock into the reactor. This feedstock must be uniform, such as the rubber powder noted in processing plants, to prevent clogs and ensure a smooth flow.

Steady-State Operation

The reactor in a continuous system maintains a stable, high temperature zone. The material moves through this zone, undergoing pyrolysis as it travels from the inlet to the outlet without any process interruptions.

Simultaneous Product Removal

As the feedstock is processed, the resulting products—pyrolysis oil, syngas, and solid char—are extracted from the system at different points in real-time. The non-condensable gas is immediately recycled to fuel the reactor, maintaining thermal efficiency.

Understanding the Key Operational Differences

Feedstock Requirements

Batch systems are more forgiving, capable of handling non-uniform, larger materials like whole tires. Continuous systems demand consistent, often shredded or powdered, feedstock to maintain their uninterrupted flow.

Operating Scale and Throughput

Batch plants are suited for smaller-scale operations, typically processing 12-16 tons per day. Continuous plants are designed for industrial scale, handling 12-35 tons or more daily by eliminating downtime.

Labor and Automation

The start-stop nature of batch processing requires significant manual labor for loading and unloading. Continuous systems are highly automated, reducing labor costs but requiring more sophisticated technical oversight.

Energy Efficiency

Continuous systems are inherently more energy-efficient. They avoid the repeated energy loss of heating and cooling a massive reactor, making better use of recycled syngas to maintain a constant operating temperature.

Making the Right Choice for Your Operation

Choosing the correct system requires a clear understanding of your specific goals and resources.

- If your primary focus is operational flexibility and lower initial cost: A batch system is the logical choice, especially if your feedstock supply is varied or inconsistent.

- If your primary focus is large-scale production and maximum efficiency: A continuous system is necessary to achieve the economies of scale and automation for high-volume operations.

- If you are scaling up from a smaller operation: A semi-continuous design, which automates the discharge process to reduce cooling time, can serve as an effective transitional step.

Ultimately, aligning the technology with your feedstock availability, production targets, and capital investment will determine the success of your pyrolysis venture.

Summary Table:

| Feature | Batch Pyrolysis | Continuous Pyrolysis |

|---|---|---|

| Operational Flow | Cyclical (load, process, cool, unload) | Uninterrupted, steady-state |

| Typical Daily Throughput | 12-16 tons | 12-35+ tons |

| Feedstock Flexibility | High (handles large, non-uniform materials) | Low (requires uniform, pre-processed material) |

| Automation & Labor | Higher manual labor | Highly automated, lower labor |

| Energy Efficiency | Lower (repeated heating/cooling cycles) | Higher (constant temperature, gas recycling) |

| Ideal For | Smaller scale, varied feedstock, lower initial investment | Large-scale, high-volume, uniform feedstock |

Ready to optimize your pyrolysis operation? The right equipment is critical to your project's efficiency and profitability. KINTEK specializes in high-performance lab equipment and consumables for testing and scaling pyrolysis processes. Our experts can help you select the perfect system—whether batch or continuous—to match your specific feedstock and production goals. Contact our team today for a personalized consultation and discover how KINTEK solutions can power your success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the different types of pyrolysis machines? Choose the Right System for Your Output