While both are forms of densified biomass, the fundamental differences between briquettes and pellets lie in their size, density, and production method. These distinctions are not trivial; they directly dictate the type of equipment they can be used in and the applications they are best suited for, making one ideal for automated residential heating and the other for large-scale industrial use.

The choice between briquettes and pellets is not about which fuel is inherently "better," but which is appropriate for the scale and automation requirements of your combustion system. Pellets are engineered for automated, precision-controlled systems, while briquettes are a bulk fuel for larger, often manually-fed, industrial applications.

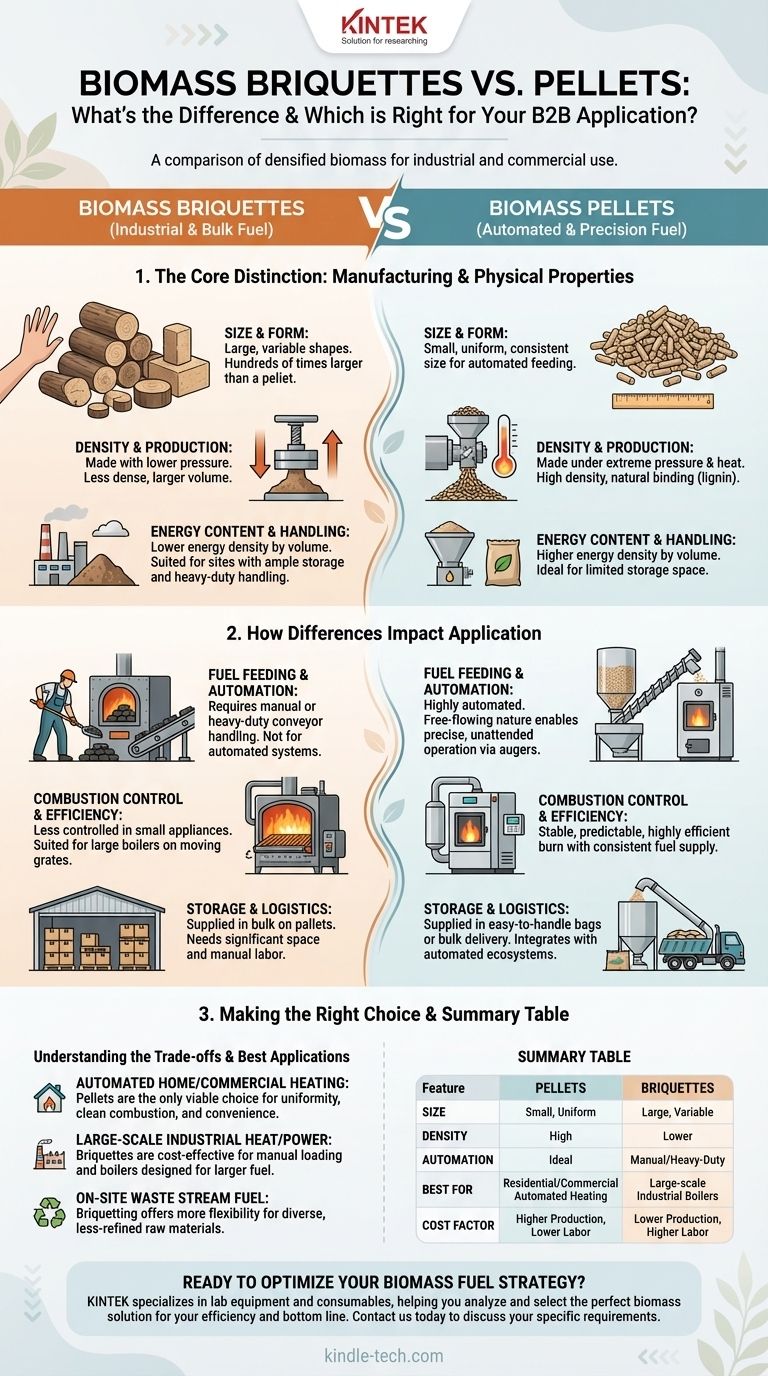

The Core Distinction: Manufacturing and Physical Properties

The characteristics of each fuel type are a direct result of how they are made. This process determines their suitability for different types of combustion technology.

### Size and Form Factor

Pellets are small, cylindrical, and highly uniform, typically measuring 6-8 millimeters in diameter and 10-30 millimeters in length. Their consistent size is a critical design feature.

Briquettes are significantly larger and can come in various shapes, including cylindrical logs, pucks, or rectangular blocks. Their diameter often ranges from 50 to 100 millimeters, making them hundreds of times larger than a single pellet.

### Density and Production Process

Both fuels are made by compressing raw biomass like sawdust, wood chips, or agricultural waste. However, the intensity of this process differs significantly.

Pellets are created in a pellet mill under extreme pressure and heat. This process forces the natural lignin within the wood to act as a binder, creating a very dense and durable product. No additional adhesives are needed.

Briquettes are typically formed using a mechanical piston or screw press that applies lower pressure than a pellet mill. This results in a product that is generally less dense than pellets.

### Energy Content and Handling

Because pellets are denser, they have a higher energy density by volume. This means you can store more potential energy in a smaller space, a key advantage for residential and commercial sites with limited storage.

Briquettes, being less dense, offer less energy for the same volume. Their bulk and weight make them more suited for industrial sites with ample space and heavy-duty handling equipment.

How These Differences Impact Application

The physical properties of pellets and briquettes directly determine how they are used, stored, and burned.

### Fuel Feeding and Automation

This is the most critical difference. The small, uniform, and free-flowing nature of pellets allows them to be used in highly automated systems. Augers (corkscrew-like feeders) can precisely transport them from a storage hopper to the combustion chamber, enabling unattended operation.

Briquettes are too large and irregular for this type of automated system. They must be loaded manually into stoves or boilers or moved with heavy-duty industrial conveyors, requiring direct labor.

### Combustion Control and Efficiency

Pellets provide a stable, predictable, and highly efficient burn. The automated feed system supplies a consistent amount of fuel, allowing the appliance to maintain optimal combustion for maximum heat output and minimal emissions.

The combustion of briquettes in smaller appliances is less controlled, behaving more like traditional firewood. In large industrial boilers, however, their size is an asset, as they can be burned on moving grates designed for bulk fuels.

### Storage and Logistics

Pellets are typically supplied in easy-to-handle bags (e.g., 40 lbs / 15 kg) or delivered in bulk by tanker trucks that can blow them directly into a dedicated silo. This integrates perfectly with the automated ecosystem.

Briquettes are almost always packaged in bulk and delivered on pallets. They require more physical space for storage and manual labor to move and load into the boiler.

Understanding the Trade-offs

Choosing a fuel means choosing a system, and each comes with its own set of economic and operational considerations.

### The Cost Equation

Pellets often have a higher production cost per ton due to the high-pressure, energy-intensive manufacturing process. However, this initial cost can be offset by higher combustion efficiency and the significant labor savings from automation.

Briquettes are frequently cheaper to produce, making their cost per ton lower. For a large industrial user where fuel is a major expense and manual labor is already part of the workflow, briquettes can be the more economical choice.

### Equipment Compatibility is Non-Negotiable

You cannot use briquettes in a pellet stove or boiler. The feed mechanism (the auger) is designed only for small pellets and would immediately jam and break if a briquette were introduced. The combustion chamber is also sized for the controlled burn of small pellets.

Conversely, while you could technically burn pellets in a large boiler designed for briquettes or logs, it would be inefficient and defeat the purpose of their design for automated feeding.

### Raw Material Flexibility

The briquetting process is often more forgiving of varied and less-refined raw materials. A briquette press can handle larger wood chips or fibrous agricultural residues that would need to be ground down extensively for a pellet mill. This can be an advantage for facilities looking to convert their own specific waste streams into fuel.

Making the Right Choice for Your Application

Your decision depends entirely on the scale of your operation and your need for automation.

- If your primary focus is automated home or commercial heating: Pellets are the only viable choice due to their uniformity, enabling the automated feeding, clean combustion, and convenience these systems are designed for.

- If your primary focus is large-scale industrial heat or power: Briquettes are often the more cost-effective fuel, especially when manual loading is feasible and the boiler is designed to handle larger, non-uniform fuel stock.

- If your primary focus is creating fuel from your own specific waste stream: Briquetting technology may offer more flexibility for diverse raw materials, making it an excellent option for on-site fuel production.

By understanding that the fuel and the appliance are two parts of a single system, you can confidently invest in a biomass solution that is perfectly aligned with your operational goals.

Summary Table:

| Feature | Pellets | Briquettes |

|---|---|---|

| Size | Small, uniform (6-8mm diameter) | Large, variable shapes (50-100mm diameter) |

| Density | High (extreme pressure process) | Lower (mechanical press) |

| Automation | Ideal for automated feeding systems | Requires manual or heavy-duty handling |

| Best For | Residential/commercial automated heating | Large-scale industrial boilers |

| Cost Factor | Higher production cost, lower labor | Lower production cost, higher labor |

Ready to optimize your biomass fuel strategy?

Whether you're scaling up an industrial process or automating a commercial heating system, choosing the right fuel is critical for efficiency and cost-effectiveness. KINTEK specializes in lab equipment and consumables, serving laboratory needs, and our experts can help you analyze your specific requirements.

Contact us today to discuss how the right biomass solution can enhance your operational efficiency and bottom line. Let's find the perfect fit for your application together!

Visual Guide

Related Products

- Laboratory Jaw Crusher

- Graphite Vacuum Continuous Graphitization Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What is the function of laboratory crushing and sieving systems in biomass pretreatment? Optimize Your Lab Results

- What is a jaw crusher for labs? The Essential First Step for Accurate Sample Analysis

- What laboratory apparatus is used for grinding? Match the Right Mill to Your Sample Material

- What is the primary function of an industrial jaw crusher in recycled aggregate concrete? Boost Efficiency & Quality

- What is used for grinding in the lab? Match the Right Mill to Your Sample's Properties