At its core, a laboratory jaw crusher is a specialized piece of equipment designed to perform the first step in sample preparation: breaking down large, hard materials into smaller, more manageable, and uniform pieces. It uses immense compressive force between a fixed and a moving jaw plate to reduce solids like rocks, ores, and minerals into coarse gravel or fine powder for subsequent analysis.

The true purpose of a laboratory jaw crusher is not simply to break things. It is to create a consistent, representative sample from a larger bulk material, which is the foundational step for achieving accurate and repeatable analytical results in any scientific or industrial setting.

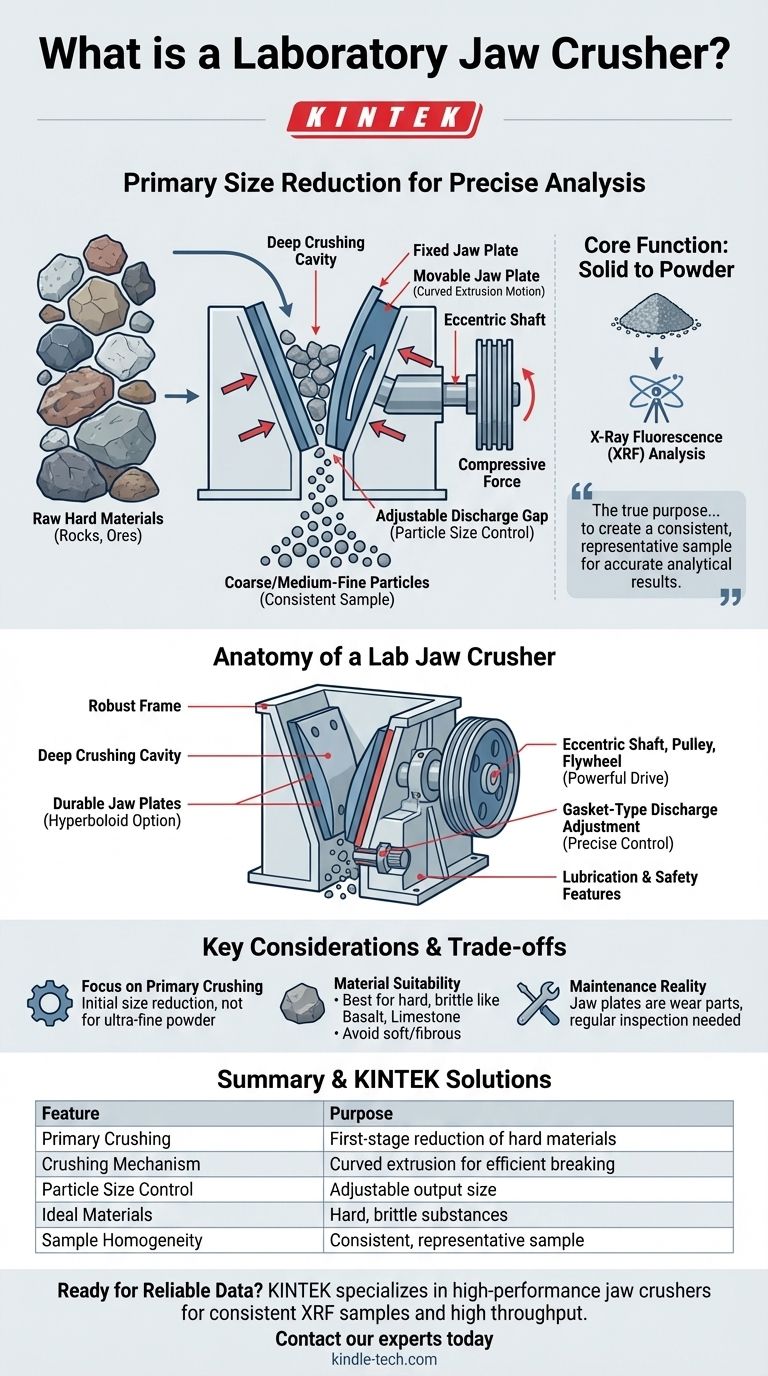

The Core Function: From Solid Rock to Analyzable Powder

To understand the value of a jaw crusher, you must first understand the problem it solves. Raw materials are rarely uniform, and analyzing a single large chunk provides a poor representation of the whole.

Why Particle Size Reduction is Critical

Accurate molecular analysis, such as X-Ray Fluorescence (XRF), requires samples to be homogenous and finely powdered. Reducing large, inconsistent pieces into uniform particles is essential.

This process ensures that the small portion of material being analyzed is statistically representative of the entire batch. It facilitates easier handling, processing, and ultimately, produces reliable data.

How the Crushing Mechanism Works

A laboratory jaw crusher employs a method known as curved extrusion. The material is fed into a deep crushing cavity, which is a V-shaped chamber formed by a fixed jaw plate and a movable jaw plate.

An eccentric shaft drives the movable jaw in a combined downward and forward motion. This action squeezes and breaks the material against the fixed jaw.

As the moving jaw retreats, the angle with a component called the toggle plate changes, allowing the jaw to pull away. This opens a gap at the bottom, discharging the newly crushed particles.

Anatomy of a Laboratory Jaw Crusher

The design of a lab jaw crusher is optimized for efficiency, durability, and precise control over the final output.

The Crushing Chamber

The heart of the machine is the deep crushing cavity, designed with no "dead zones" to improve feeding and prevent material from packing.

The jaw plates themselves are often made of highly durable materials. Some advanced designs use a hyperboloid shape, which reduces wear and can extend the life of the jaws significantly compared to standard plates.

The Drive and Adjustment System

The crushing action is powered by an eccentric shaft, a large pulley, and a flywheel, which provides the momentum for consistent and powerful crushing cycles.

Critically, these crushers feature a gasket-type discharge port adjustment. This allows the operator to precisely control the gap at the bottom of the jaws, determining the maximum size of the output particles.

Support and Safety Features

The entire assembly is held in a robust frame. A reliable lubrication system ensures smooth operation, while safety guards and easily replaceable parts minimize maintenance workload and ensure operator safety.

Understanding the Trade-offs and Key Considerations

While highly effective, a jaw crusher is a specific tool for a specific job. Understanding its limitations is key to using it properly.

The Focus on Primary Crushing

A jaw crusher excels at primary crushing—the first stage of size reduction. It efficiently takes large feed material and breaks it down to a coarse or medium-fine size.

It is not designed to produce the ultra-fine powders required for many final analyses. It is the crucial first step, often followed by a secondary mill or pulverizer.

Material Suitability

These machines are engineered for hard, brittle materials. They are ideal for samples like basalt, river pebble, limestone, and various ores.

They are not suitable for soft, elastic, or fibrous materials. Attempting to crush such samples can lead to clogging and inefficient operation rather than the clean fracture a jaw crusher is designed to create.

Maintenance as a Reality

The jaw plates are wear parts. While high-quality designs last a long time, they will eventually need to be replaced. Regular inspection and adherence to the lubrication schedule are necessary for long-term reliability.

Making the Right Choice for Your Lab

Selecting the right equipment depends entirely on your material and your analytical goals.

- If your primary focus is high-throughput preparation of hard, brittle materials: A jaw crusher is the ideal and most efficient tool for the initial size reduction stage.

- If your primary focus is achieving extremely fine powders for analysis (e.g., XRF): A jaw crusher is the essential first step, which must be followed by a secondary pulverizer or fine-grinding mill.

- If your primary focus is processing soft, sticky, or fibrous samples: You must investigate a different type of equipment, such as a cutting mill, as a jaw crusher is inappropriate for this task.

Ultimately, choosing the correct primary crushing method is the foundation upon which all subsequent, reliable analytical data is built.

Summary Table:

| Feature | Purpose & Benefit |

|---|---|

| Primary Crushing | First-stage size reduction of large, hard materials (rocks, ores). |

| Crushing Mechanism | Curved extrusion between jaw plates for efficient breaking. |

| Particle Size Control | Adjustable discharge gap determines final output size. |

| Ideal Materials | Hard, brittle substances like basalt, limestone, and minerals. |

| Sample Homogeneity | Creates a consistent, representative sample for accurate analysis. |

Ready to build a foundation of reliable analytical data?

Choosing the right primary crusher is critical for your lab's success. KINTEK specializes in high-performance laboratory jaw crushers and consumables designed for durability and precise particle size control.

We provide solutions that help you:

- Achieve consistent, homogenous samples for techniques like XRF analysis.

- Increase throughput with efficient primary crushing of hard materials.

- Minimize downtime with robust equipment and readily available wear parts.

Let's discuss your specific sample preparation needs. Contact our experts today to find the perfect jaw crusher for your laboratory.

Visual Guide

Related Products

- Laboratory Jaw Crusher

- Sealed Jaw Crusher High Efficiency Environmental Protection Safe and Reliable

- Powerful Plastic Crusher Machine

- Three-dimensional electromagnetic sieving instrument

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

People Also Ask

- How do mechanical crushing and sieving systems work for high-entropy alloy? Optimize Your Alloy Powder Production

- How do crushing and sieving systems influence silicide powder quality? Optimize Particle Size for Peak Performance

- What is the role of mechanical crushing and sieving systems in waste plastic graphene conversion? Optimize Pretreatment

- What role do laboratory crushers and standard sieves play in Datura stramonium pretreatment? Optimize Your HTL Yield

- What is the primary function of industrial crushing and sieving systems? Master Biomass Pretreatment for Success

- How does crushing equipment handle calcium carbide reducing agents? Optimize Boron Mud Thermal Reduction

- Why is laboratory crushing or grinding equipment necessary for fluoride waste? Optimize Glass Matrix Vitrification

- What is the primary function of multi-stage crushing and grinding equipment in biomass hydrothermal treatment?