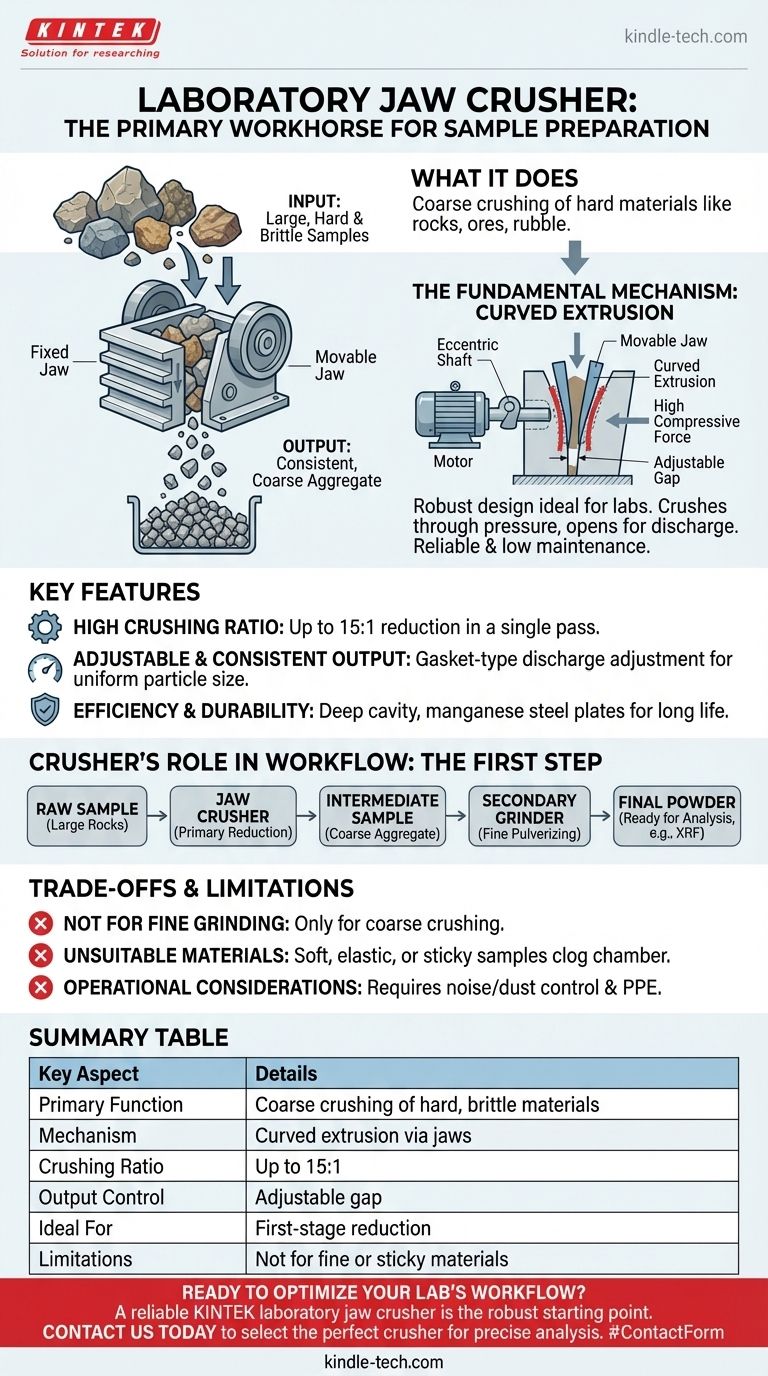

In a laboratory setting, a jaw crusher serves a single, critical purpose: it is the primary workhorse for the initial, coarse crushing of hard and brittle materials. It takes large, unmanageable samples like rocks, ores, or construction rubble and aggressively reduces them into smaller, more uniform pieces that are suitable for the next stage of processing or analysis.

The primary role of a laboratory jaw crusher is not to produce a final, fine powder, but to perform the essential first step of sample reduction. It efficiently breaks down large, tough samples into a consistent, coarse aggregate, preparing them for finer grinding by other specialized equipment.

The Fundamental Crushing Mechanism

How It Works: Curved Extrusion

The crusher uses a simple and powerful mechanism. A motor drives an eccentric shaft, which causes a movable jaw to oscillate.

As the movable jaw moves toward a fixed jaw, it presses the material between them, crushing it through immense compressive force. This is known as curved extrusion.

When the movable jaw retracts, a gap opens at the bottom of the crushing cavity. This allows the smaller, crushed material to fall through and be collected.

Why This Design Is Ideal for Labs

This mechanism is exceptionally robust, making it perfect for breaking down very hard materials like basalt, granite, and various ores without frequent failure.

Its mechanical simplicity ensures high reliability and minimal maintenance workload, which are critical advantages in a busy laboratory environment.

Key Features of a Laboratory Jaw Crusher

High Crushing Ratio

These machines offer a high crushing ratio, often around 15:1. This means they can reduce a sample to approximately one-fifteenth of its original size in a single pass.

This level of efficiency rapidly prepares a bulk sample for subsequent steps, saving significant time and manual effort in the lab.

Adjustable and Consistent Output

The output particle size is precisely controlled by a gasket-type discharge adjustment. By adding or removing shims, an operator can change the minimum gap between the jaws.

This feature ensures that the crushed material is of a uniform particle size. Consistency is essential for obtaining a representative subsample and for the effective operation of secondary grinders.

Efficiency and Durability by Design

Modern lab jaw crushers feature a deep crushing cavity with no dead zones. This design improves the feeding of material and prevents it from getting stuck, increasing overall throughput.

The jaw plates themselves are typically made of highly durable manganese steel or similar alloys to withstand extreme wear, extending their operational life significantly even under heavy use.

The Crusher's Role in an Analytical Workflow

The First Step in Sample Reduction

A jaw crusher is almost always the first stage in a multi-step sample preparation process. Think of it as the sledgehammer used to break down the initial, large sample into a manageable form.

It does not produce the final powder needed for analysis. Its job is to create particles small enough (e.g., a few millimeters) to be fed into a finer grinder, like a pulverizer or disc mill.

Preparing Samples for Precise Analysis

Techniques like X-Ray Fluorescence (XRF) spectroscopy require a sample to be a homogenous, fine powder to ensure accurate and repeatable results.

The jaw crusher is the indispensable starting point for achieving this. By turning a large, non-uniform rock into predictable, smaller pieces, it makes the final pulverizing step both possible and efficient.

Understanding the Trade-offs and Limitations

Not for Fine Grinding

The most significant limitation is that a jaw crusher is only for coarse crushing. It cannot produce the fine powders (typically measured in microns) required for most modern analytical methods on its own.

Unsuitable for Certain Materials

Jaw crushers are designed for hard and brittle materials. They perform poorly with soft, elastic, or sticky samples (like clay or some polymers), which can extrude or clog the crushing chamber instead of fracturing.

Operational and Safety Considerations

The crushing process is inherently noisy and generates significant dust. Proper facility engineering, including ventilation, dust extraction systems, and the use of personal protective equipment, is mandatory for safe operation.

How to Apply This to Your Project

Before selecting your equipment, clearly define the goal of your sample preparation.

- If your primary focus is preparing large rock or ore samples for further grinding: A laboratory jaw crusher is the correct and essential first piece of equipment for this primary reduction.

- If your primary focus is creating a final, analysis-ready powder from an already coarse sample: You need a secondary grinder, such as a pulverizer or ring mill, not a jaw crusher.

- If your primary focus is processing diverse industrial materials like slag, glass, or rubble: The jaw crusher's robust design and high throughput make it an ideal choice for bulk reduction.

Ultimately, understanding the jaw crusher's role as the powerful first step in sample reduction empowers you to build an efficient and effective laboratory workflow.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Function | Coarse crushing of hard, brittle materials (rocks, ores, construction rubble) |

| Crushing Mechanism | Curved extrusion via movable and fixed jaws |

| Typical Crushing Ratio | Up to 15:1 |

| Output Control | Adjustable particle size via gasket-type discharge adjustment |

| Ideal For | First-stage sample reduction in analytical workflows (e.g., before XRF analysis) |

| Limitations | Not for fine grinding; unsuitable for soft, elastic, or sticky materials |

Ready to optimize your lab's sample preparation workflow?

A reliable laboratory jaw crusher from KINTEK is the robust, high-efficiency starting point you need for reducing large, hard samples into uniform, manageable pieces. Whether you're processing geological samples, industrial minerals, or construction materials, our crushers deliver consistent performance and durability to keep your lab running smoothly.

Contact us today using the form below to discuss your specific needs. Our experts will help you select the perfect jaw crusher to enhance your lab's productivity and prepare your samples for precise analysis.

Visual Guide

Related Products

- Laboratory Jaw Crusher

- Sealed Jaw Crusher High Efficiency Environmental Protection Safe and Reliable

- Powerful Plastic Crusher Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the primary function of industrial crushing and sieving systems? Master Biomass Pretreatment for Success

- Why are industrial-grade crushing and sieving systems required for nickel-based filler powders? Expert Solutions

- What role do mechanical crushing systems play in lignocellulosic pretreatment? Maximize Surface Area & Yield

- What advantages do hammer mills offer in the primary size reduction of lignocellulose? Boost Biomass Processing Efficiency

- What role does a laboratory crushing and sieving system play in the shaping stage of CoCeBa catalysts? Precision Sizing

- What is the function of industrial crushing and sieving systems in MSW? Optimize Your Waste-to-Energy Pretreatment

- What is the role of crushing and sieving systems in peanut shell pretreatment? Optimize Your Levulinic Acid Production

- What is the function of a high-speed laboratory crusher for nanoparticle synthesis? Optimize Your Botanical Extraction