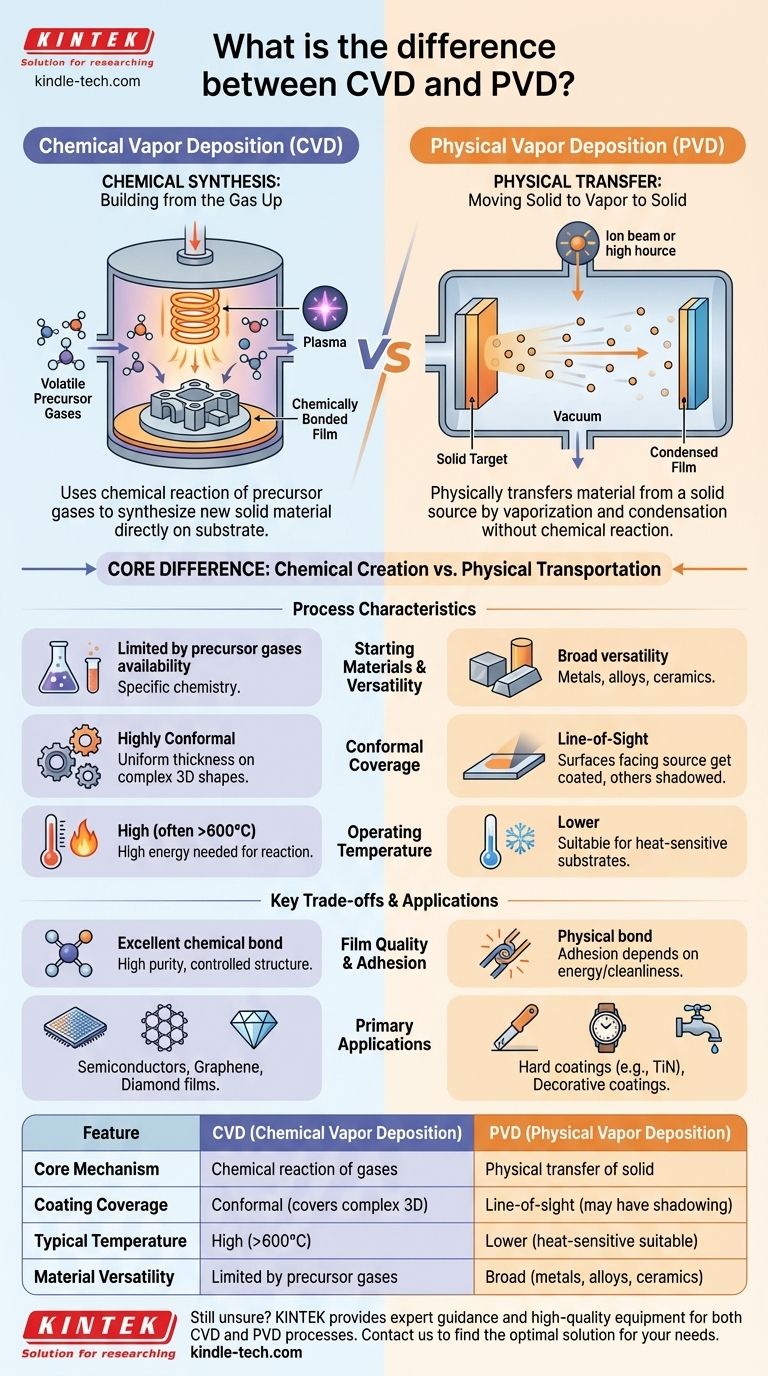

The fundamental difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in how the coating material arrives and forms on the surface of a part. CVD uses a chemical reaction between precursor gases to synthesize a new solid material directly on the substrate. In contrast, PVD physically transfers a material from a solid source to the substrate by vaporizing it and allowing it to condense, without a chemical reaction defining the final film.

The core distinction is not just a matter of process, but of creation versus transportation. CVD chemically creates a new film on the surface, while PVD physically moves an existing material onto the surface. This single difference dictates the applications, benefits, and limitations of each technique.

The Core Mechanism: Chemical Synthesis vs. Physical Transfer

To select the right process, you must first understand the fundamental principle that separates them. One builds a coating from atomic building blocks, while the other transports it whole.

How CVD Works: Building from the Gas Up

In CVD, the part to be coated is placed inside a reaction chamber. Volatile precursor gases containing the required chemical elements are then introduced.

High temperatures (or plasma) provide the energy needed to cause these gases to react or decompose on the part's surface. This chemical reaction synthesizes a new, stable, and solid thin film that is chemically bonded to the substrate. It's akin to atomic-level construction, where a new material is built molecule by molecule.

How PVD Works: Moving Solid to Vapor to Solid

In PVD, the process begins with a solid source material, known as a "target," which has the same composition as the desired coating. This target is placed in a vacuum chamber with the substrate.

Energy is then applied to the target—often through ion bombardment (sputtering) or high heat (evaporation)—causing atoms or molecules to be ejected from its surface. These vaporized particles travel in a straight line through the vacuum and condense onto the cooler substrate, forming a thin film. This is a line-of-sight physical process, much like spray painting with individual atoms.

Key Process Characteristics

The difference in mechanism leads to distinct process characteristics, influencing everything from the materials you can use to the shape of the parts you can coat.

Starting Materials and Versatility

CVD is limited by the availability of suitable precursor chemicals. You must be able to find gases that are volatile, stable enough to be transported, but reactive enough to deposit a film under specific conditions.

PVD is far more versatile in its choice of materials. Virtually any metal, alloy, or ceramic compound that can be made into a solid target can be deposited, offering a much broader palette of coating options.

Conformal Coverage

CVD excels at creating highly conformal coatings. Because the precursor gases can flow into and around complex geometries, the resulting film has a uniform thickness, even inside deep trenches or on intricate 3D shapes. This is a critical advantage in semiconductor manufacturing.

PVD is a line-of-sight process. The vaporized material travels in a straight path from the source to the substrate. This means surfaces not directly facing the source will receive little to no coating, an effect known as "shadowing."

Operating Temperature

Traditional CVD often requires very high substrate temperatures (often >600°C) to drive the necessary chemical reactions. This can damage or warp heat-sensitive materials like plastics or certain metal alloys.

Newer variants like Plasma-Enhanced CVD (PECVD) use plasma to provide energy, allowing deposition at much lower temperatures. PVD processes can also be run at lower temperatures than thermal CVD, making them more suitable for coating temperature-sensitive parts.

Understanding the Trade-offs

Neither method is universally superior. The optimal choice is determined by the specific requirements of your application, and each comes with clear trade-offs.

Film Quality and Adhesion

Because CVD films are grown directly on the surface via chemical bonds, they often exhibit excellent adhesion and can be produced with very high purity and controlled crystalline structures. The ability to create high-quality, low-defect graphene sheets is a testament to CVD's precision.

PVD film adhesion is highly dependent on the energy of the depositing particles and the cleanliness of the substrate. While excellent adhesion can be achieved, it is a physical bond, not a chemical one.

Process Complexity and Cost

CVD processes can be complex, often dealing with toxic, corrosive, or pyrophoric precursor gases that require extensive safety and handling infrastructure.

PVD systems, while still requiring high vacuum and sophisticated power supplies, are often conceptually simpler and can be more straightforward to operate, particularly for depositing common metals and hard coatings like Titanium Nitride (TiN).

Deposition Rate

PVD processes can often achieve higher deposition rates than CVD, which can be an advantage for applications requiring thick coatings or high throughput manufacturing. CVD reactions are often the rate-limiting step.

Making the Right Choice for Your Goal

Your application's specific needs—material, geometry, and required performance—will dictate the best deposition method.

- If your primary focus is ultimate purity and uniform coverage on complex 3D geometries (e.g., semiconductors): CVD is the superior choice for its non-line-of-sight, conformal coating capability.

- If your primary focus is depositing a wide range of metals, alloys, or ceramics at relatively low temperatures: PVD offers unmatched material versatility and is more compatible with heat-sensitive substrates.

- If your primary focus is a hard, wear-resistant coating for cutting tools or components: Both are used, but PVD sputtering is an industry standard for its reliability and range of hard coating materials.

- If your primary focus is synthesizing a specific, high-quality crystalline material like diamond or graphene: CVD is the definitive method for growing such films with atomic-level precision.

By understanding the core difference between chemical synthesis and physical transfer, you can confidently select the deposition technology that best aligns with your material and performance goals.

Summary Table:

| Feature | Chemical Vapor Deposition (CVD) | Physical Vapor Deposition (PVD) |

|---|---|---|

| Core Mechanism | Chemical reaction of precursor gases | Physical transfer of solid source material |

| Coating Coverage | Conformal (covers complex 3D shapes) | Line-of-sight (may have shadowing) |

| Typical Temperature | High (often >600°C) | Lower (suitable for heat-sensitive substrates) |

| Material Versatility | Limited by available precursor gases | Broad (metals, alloys, ceramics) |

| Primary Applications | Semiconductors, graphene, diamond films | Hard coatings (e.g., TiN), decorative coatings |

Still unsure which deposition method is right for your application? KINTEK specializes in providing expert guidance and high-quality lab equipment for both CVD and PVD processes. Whether you need to coat complex 3D parts with CVD's conformal coverage or apply durable metal coatings with PVD's versatility, our team can help you select the optimal solution for your laboratory needs. Contact us today to discuss your specific requirements and discover how our expertise can enhance your research and development outcomes.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the dual function of the substrate heater in MW-SWP CVD hBN synthesis? Optimize Your Thin Film Growth

- Why is carbon coating important? Boost Battery Performance and Longevity

- What are the technical advantages of using a cold-wall horizontal reactor for TiO2? Maximize Efficiency & Film Purity

- What is the vapor deposition of metals? Build Superior, High-Purity Metal Coatings

- What is chemical vapour deposition for thin films? A Guide to High-Performance Surface Engineering

- What is the temperature range of LPCVD? From 425°C to 900°C for Superior Thin Films

- What is the principle of chemical vapor deposition? Build High-Performance Coatings Through Controlled Chemistry

- What is the construction of chemical vapour deposition? Build High-Purity Films with Precision Equipment