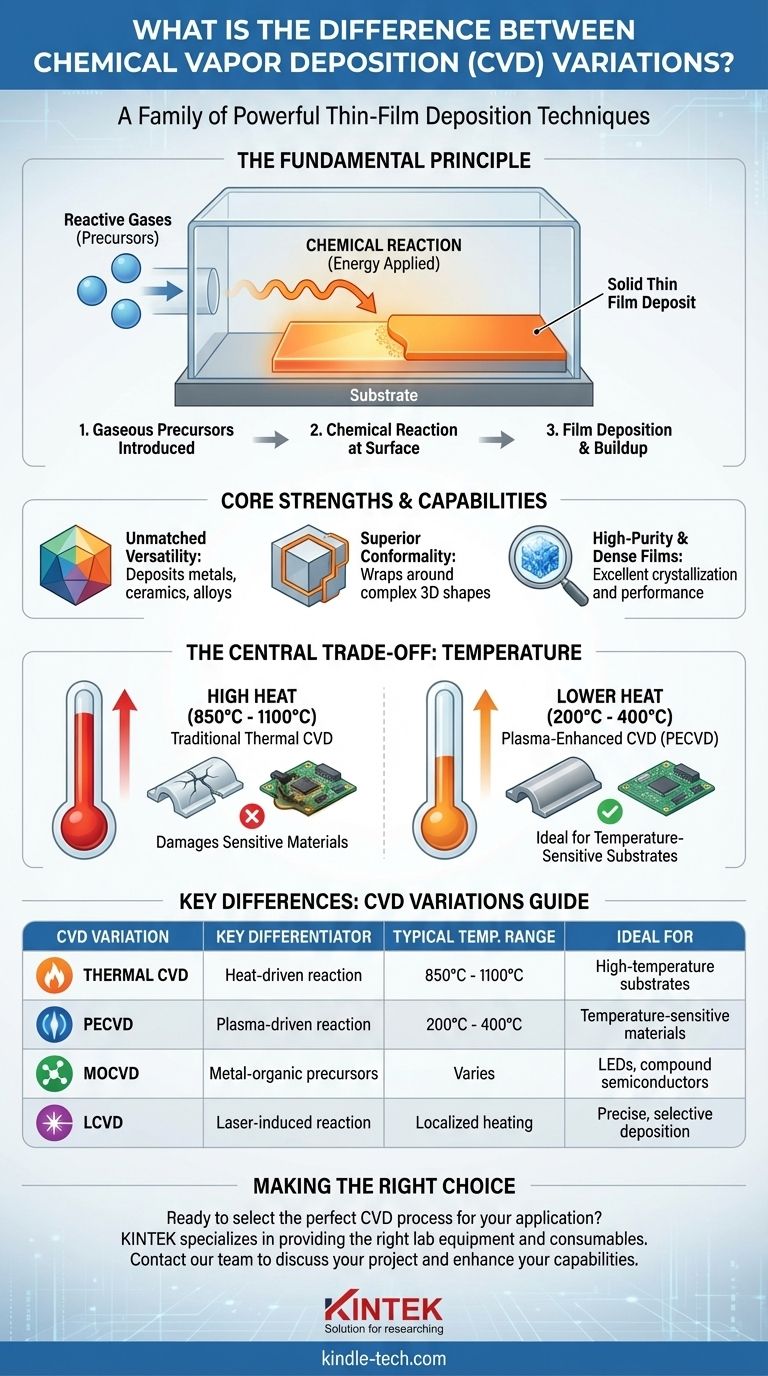

At its core, Chemical Vapor Deposition (CVD) is not a single process, but a family of powerful techniques used to create exceptionally high-quality, thin solid films on a surface. It works by introducing reactive gases (precursors) into a chamber, which then undergo a chemical reaction at or near a heated object (the substrate), causing a new material to deposit and build up layer by layer. This fundamental difference—creating material via a chemical reaction from a gas—is what separates it from other methods.

Chemical Vapor Deposition excels at producing pure, uniform coatings that can completely "wrap around" complex 3D shapes. Its primary challenge is the high temperature required for traditional methods, which has driven the development of specialized variations like Plasma-Enhanced CVD (PECVD) for temperature-sensitive applications.

The Fundamental Principle of CVD

To understand the differences between CVD types, you must first grasp the core process that unites them. It is a method of synthesis, not just application.

How It Works: The Three-Step Process

Every CVD process follows three basic steps. Think of it like a specialized form of "baking" a solid layer onto a surface using gaseous ingredients.

- Introduction of Gaseous Precursors: Volatile chemical compounds, which contain the elements you want to deposit, are introduced into a reaction chamber in gas form.

- Chemical Reaction: Energy is applied—typically heat—which causes the precursor gases to react or decompose at or near the substrate's surface.

- Film Deposition: The non-volatile, solid products of that reaction deposit onto the substrate, forming a dense, uniform, and solid thin film.

What Defines the CVD Family

Three characteristics are true for all forms of CVD: a chemical change occurs, the deposited material originates from an external gas source, and the reactants must be in a gas phase to participate in the reaction.

Core Strengths and Capabilities

The reason CVD is so widely used in fields from semiconductors to aerospace is its unique combination of advantages.

Unmatched Versatility

CVD can be used to deposit an incredibly wide range of materials. This includes metals, non-metal films like silicon nitride, multi-component alloys, and advanced ceramics.

Superior Conformality

Because the deposition comes from a gas that fills the entire chamber, CVD is a non-line-of-sight process. It provides excellent "wrap-around" coverage on complex, irregularly shaped surfaces, something that line-of-sight methods like Physical Vapor Deposition (PVD) struggle with.

High-Purity and Dense Films

The process naturally produces films of very high purity and density with low residual stress. The resulting layers have good crystallization, which is critical for the performance of electronic and optical components.

Precise Control Over Film Properties

By carefully adjusting process parameters like temperature, pressure, and gas composition, operators can precisely control the final film's chemical composition, crystal structure, and grain size.

Understanding the Trade-offs: The Challenge of Temperature

No technology is without its limitations. For CVD, the central trade-off revolves almost entirely around the energy required to drive the chemical reaction.

The High Heat of Thermal CVD

The simplest and most traditional form of CVD relies solely on heat to initiate the reaction. This requires very high temperatures, often between 850°C and 1100°C.

This extreme heat is the technology's main drawback, as it can damage or destroy many substrate materials, such as plastics, certain alloys, and completed electronic devices.

Key Differences: A Guide to CVD Variations

The need to overcome the high-temperature limitation of traditional CVD has led to the development of several important variations. The primary difference between them is the type of energy used to drive the chemical reaction.

Thermal CVD: The High-Temperature Original

This is the foundational method. It uses a furnace to heat the entire chamber and substrate, providing the thermal energy for the reaction. It is simple and effective but limited to substrates that can withstand extreme heat.

Plasma-Enhanced CVD (PECVD): The Low-Temperature Workhorse

PECVD is the most significant evolution. Instead of relying solely on heat, it uses an electric field to generate a plasma (an energized, ionized gas).

This plasma provides the energy to drive the chemical reaction, allowing deposition to occur at much lower temperatures—often 200°C to 400°C. This breakthrough makes it possible to coat temperature-sensitive materials.

Laser and Hot-Filament CVD: For Precision and Special Cases

Laser CVD (LCVD) uses a focused laser beam to locally heat a small spot on the substrate. This allows for precise, selective deposition without heating the entire object.

Hot-Filament CVD (HFCVD) uses a heated wire (filament) placed near the substrate to thermally decompose the precursor gases, which then deposit on the cooler substrate. It is often used for depositing specific materials like diamond films.

MOCVD and Liquid Injection: Expanding the Precursor Toolkit

These variations are defined more by the type of precursor used. Metal-Organic CVD (MOCVD) uses metal-organic compounds, which are vital for manufacturing high-performance LEDs and other compound semiconductors. Other methods like Direct Liquid Injection (DLI-CVD) allow for the use of liquid precursors that are vaporized just before entering the chamber.

Making the Right Choice for Your Goal

Selecting the correct CVD method depends entirely on your substrate material and desired film properties.

- If your primary focus is coating a robust, high-temperature substrate: Traditional Thermal CVD offers excellent film quality with simpler equipment.

- If your primary focus is coating a temperature-sensitive material (like plastic or certain electronics): Plasma-Enhanced CVD (PECVD) is the essential and standard choice.

- If your primary focus is depositing material on a very specific, targeted area: Laser CVD (LCVD) provides the necessary precision.

- If your primary focus is coating a complex, 3D object uniformly: The inherent non-line-of-sight nature of most CVD processes makes them a superior choice to other methods.

Ultimately, understanding Chemical Vapor Deposition means recognizing it as a versatile family of processes, each tailored to solve a specific set of material and temperature challenges.

Summary Table:

| CVD Variation | Key Differentiator | Typical Temperature Range | Ideal For |

|---|---|---|---|

| Thermal CVD | Heat-driven reaction | 850°C - 1100°C | High-temperature substrates |

| PECVD | Plasma-driven reaction | 200°C - 400°C | Temperature-sensitive materials |

| MOCVD | Metal-organic precursors | Varies | LEDs, compound semiconductors |

| LCVD | Laser-induced reaction | Localized heating | Precise, selective deposition |

Ready to select the perfect CVD process for your application?

KINTEK specializes in providing the right lab equipment and consumables for your specific Chemical Vapor Deposition needs. Whether you require the high-temperature capability of Thermal CVD systems or the versatility of Plasma-Enhanced CVD (PECVD) for sensitive substrates, our experts can help you achieve superior film quality, uniformity, and performance.

Contact our team today to discuss your project and discover how KINTEK's solutions can enhance your laboratory's capabilities and accelerate your research and development.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate