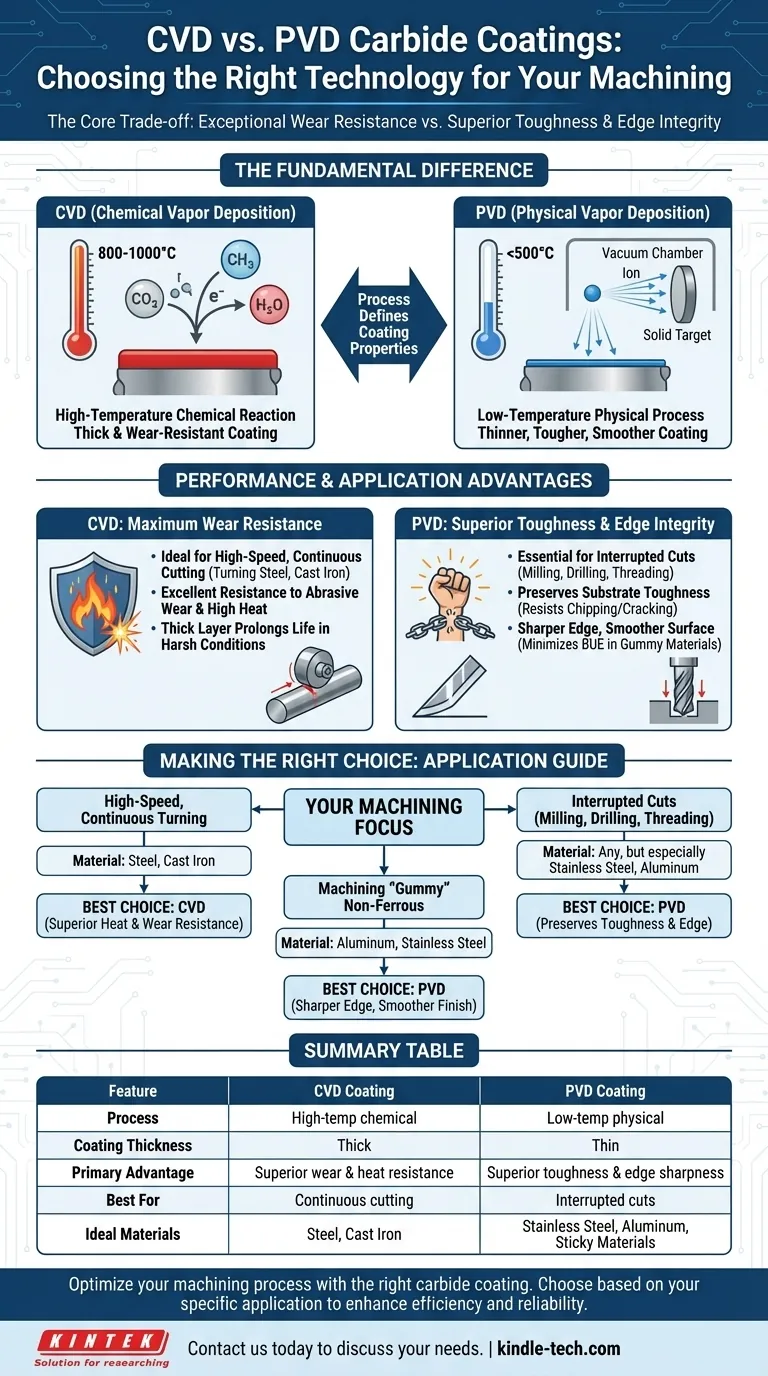

The fundamental difference between CVD and PVD coatings lies in the process used to apply them to a carbide tool. Chemical Vapor Deposition (CVD) is a high-temperature process that uses chemical reactions between gases to form a thick, wear-resistant coating. In contrast, Physical Vapor Deposition (PVD) is a lower-temperature physical process where a solid material is vaporized and deposited, resulting in a thinner, tougher, and smoother coating.

Choosing between CVD and PVD is not a question of which is "better," but which is correct for a specific machining task. The core trade-off is between the exceptional wear resistance of CVD coatings and the superior toughness and edge integrity of PVD coatings.

How the Deposition Process Defines the Coating

The method of application—chemical versus physical—is the root cause of every performance difference between these two coating types. Understanding this process is key to understanding their behavior.

CVD: A High-Temperature Chemical Reaction

Chemical Vapor Deposition takes place inside a reactor at very high temperatures, often between 800°C and 1000°C.

Precursor gases are introduced into the chamber, where they react on the surface of the carbide tool. This chemical reaction forms a new, solid coating layer that is chemically bonded to the tool.

Because the process is driven by gas flow, the deposition is omnidirectional. This means it coats all surfaces of the insert evenly, creating a uniform and typically thick layer.

PVD: A Low-Temperature Physical Deposition

Physical Vapor Deposition is a "line-of-sight" process conducted at much lower temperatures, usually below 500°C.

A solid source material (the coating) is bombarded with high-energy ions, causing it to vaporize. This vapor then travels in a straight line and condenses onto the tools, which are strategically placed in the vacuum chamber.

This direct impingement results in a thinner coating compared to CVD. The lower process temperature is critical because it does not alter the fundamental toughness of the underlying carbide substrate.

Performance Implications: Wear Resistance vs. Toughness

The differences in temperature and deposition method create coatings with distinct advantages and disadvantages in a machine shop environment.

The CVD Advantage: Maximum Wear Resistance

The thick, chemically bonded nature of CVD coatings provides exceptional resistance to abrasive wear and high heat.

This makes CVD-coated tools the ideal choice for high-speed, continuous cutting operations, such as turning steel or cast iron, where heat and abrasion are the primary modes of tool failure.

The PVD Advantage: Superior Toughness and Edge Integrity

The lower PVD process temperature preserves the carbide substrate's inherent toughness, making the tool much more resistant to chipping and cracking.

This toughness is essential for interrupted cuts common in milling, drilling, and threading. Furthermore, the PVD process creates a smoother surface and allows for a sharper cutting edge, which reduces friction and built-up edge (BUE) when machining "gummy" materials like stainless steel and aluminum.

Understanding the Trade-offs

Neither technology is a perfect solution for all scenarios. Acknowledging their limitations is crucial for proper selection.

CVD: The Risk of Reduced Toughness

The high heat of the CVD process can create a brittle zone in the carbide substrate just below the coating. This reduces the tool's overall toughness and makes it more susceptible to failure under shock or vibration.

This is why CVD tools are generally not recommended for applications involving heavy interruptions. The coating itself can also exhibit tensile stress, which can lead to cracking.

PVD: The Limitation of Coating Thickness

PVD coatings are inherently thinner than CVD coatings. While tough, they may not offer the same extended lifespan in purely abrasive, high-heat applications where a thick layer of CVD material would simply wear away more slowly.

Edge Sharpness and Material Adhesion

CVD's omnidirectional coating process can slightly round the cutting edge, which is detrimental when a very sharp edge is needed.

PVD's line-of-sight process coats the existing edge without rounding it. This sharp, smooth edge is critical for achieving a good surface finish and preventing material from welding itself to the tool, a common problem with sticky materials.

Making the Right Choice for Your Application

Selecting the correct coating is a strategic decision that directly impacts cycle time, tool life, and part quality. Base your choice on the specific demands of the material and the machining operation.

- If your primary focus is high-speed, continuous turning of cast iron or steel: CVD is your best choice for its superior heat and wear resistance in abrasive conditions.

- If your primary focus is milling, drilling, or threading (interrupted cuts): PVD is the better option because it preserves the tool's toughness and resists chipping.

- If your primary focus is machining non-ferrous, "gummy" materials like aluminum or stainless steel: PVD is superior due to its smoother finish and ability to maintain a sharp cutting edge, which minimizes built-up edge.

By aligning the coating's properties with your specific machining challenge, you move from simply buying a tool to engineering a more efficient and reliable process.

Summary Table:

| Feature | CVD Coating | PVD Coating |

|---|---|---|

| Process | High-temperature chemical reaction (800-1000°C) | Low-temperature physical deposition (<500°C) |

| Coating Thickness | Thick | Thin |

| Primary Advantage | Superior wear resistance & heat resistance | Superior toughness & edge sharpness |

| Best For | Continuous cutting (e.g., turning steel/cast iron) | Interrupted cuts (e.g., milling, drilling, threading) |

| Ideal Materials | Steel, cast iron | Stainless steel, aluminum, sticky materials |

Optimize your machining process with the right carbide coating. Choosing between CVD and PVD can significantly impact your tool life, cycle time, and part quality. At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced coating solutions for laboratory and industrial applications. Our experts can help you select the ideal coating technology to enhance efficiency and reliability. Contact us today to discuss your specific needs and discover how KINTEK can support your laboratory and machining challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Optical Windows for Lab Applications

- Custom CVD Diamond Coating for Lab Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition