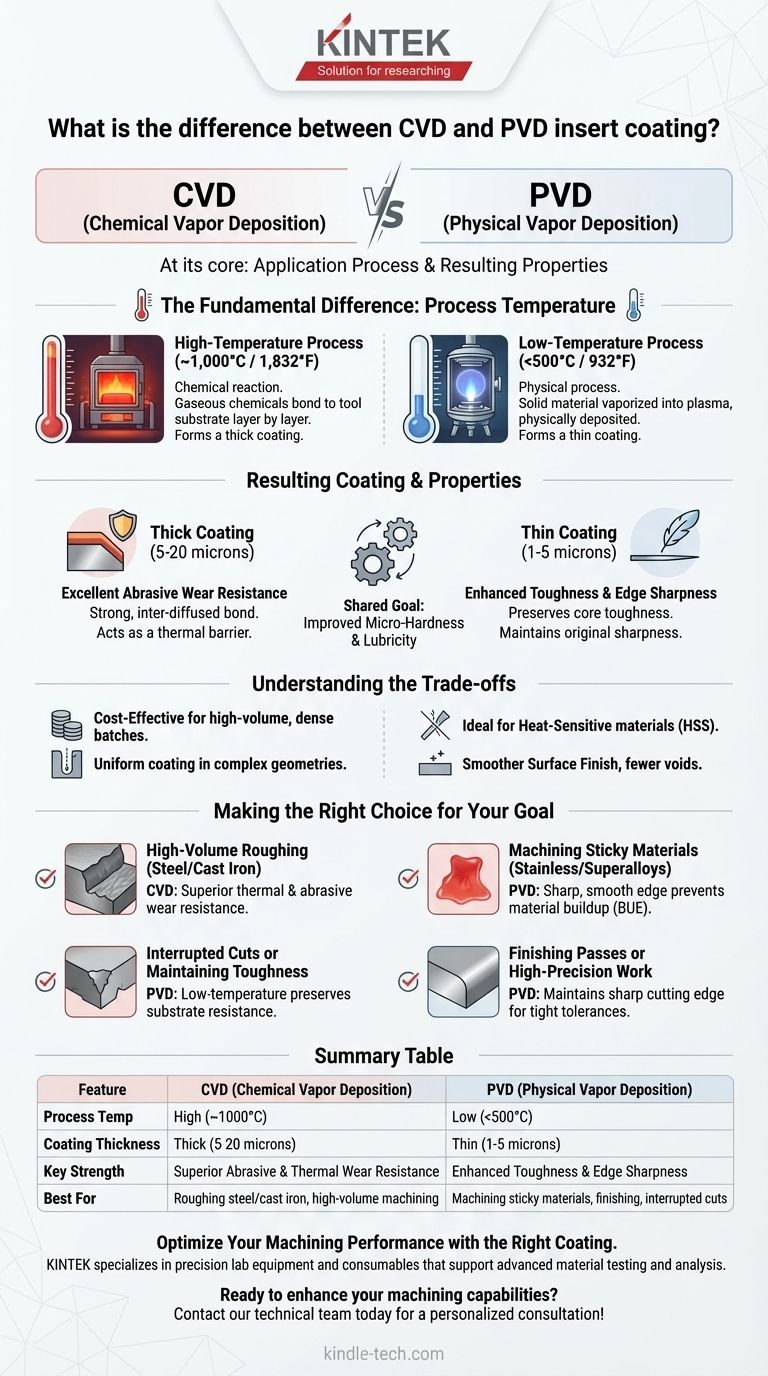

At its core, the difference between CVD and PVD coatings for cutting tool inserts comes down to the application process and the resulting properties. Chemical Vapor Deposition (CVD) is a high-temperature process that creates thick, highly wear-resistant coatings, while Physical Vapor Deposition (PVD) is a low-temperature process that produces thinner, smoother, and tougher coatings.

The choice is not about which coating is universally "better," but about matching the coating's characteristics to the specific demands of the machining application. CVD excels in high-heat, abrasive environments, whereas PVD provides the toughness and sharpness needed for more delicate or demanding materials.

The Fundamental Difference: Process Temperature

The manufacturing method is the primary distinction between CVD and PVD and dictates every other characteristic of the final coating.

CVD (Chemical Vapor Deposition): The High-Temperature Process

CVD involves a chemical reaction at very high temperatures, typically around 1,000°C (1,832°F). Gaseous chemicals react in a chamber and bond to the tool substrate, building up a coating layer by layer.

This high-temperature process creates an extremely strong, inter-diffused bond between the coating and the tool. The result is a thick coating (typically 5-20 microns) with exceptional adhesion.

PVD (Physical Vapor Deposition): The Low-Temperature Process

PVD is a physical process conducted at much lower temperatures, generally below 500°C (932°F). In a vacuum, a solid coating material is vaporized into a plasma and then physically deposited onto the tool's surface.

This method is more like a line-of-sight "spray painting" with atoms. It results in a thin coating (typically 1-5 microns) that is mechanically, not chemically, bonded to the tool.

How Process Translates to Performance

The differences in temperature and thickness directly impact how a coated insert will perform in a cut.

CVD: Superior Abrasive Wear Resistance

The thick, hard nature of CVD coatings provides outstanding protection against the heat and abrasion generated during high-speed cutting of materials like steel and cast iron. It acts as a powerful thermal barrier.

This makes CVD-coated inserts the workhorse for general-purpose machining and roughing operations where raw material removal and tool longevity under harsh conditions are key.

PVD: Enhanced Toughness and Edge Sharpness

The lower temperature of the PVD process is critical because it does not alter the core toughness of the carbide substrate. High-temperature CVD can sometimes make the underlying carbide more brittle.

Furthermore, the thinness of a PVD coating allows the original sharpness of the ground cutting edge to be maintained. A sharp edge is crucial for reducing friction and preventing built-up edge (BUE) when machining "gummy" or sticky materials like stainless steels, superalloys, and aluminum.

Shared Goal: Hardness and Lubricity

Both processes improve tool life by imparting two key properties. They add significant micro-hardness to resist abrasive wear and improve lubricity (a low coefficient of friction) to reduce heat and prevent material from sticking to the tool.

Understanding the Trade-offs

Choosing a coating requires balancing performance needs with practical and financial considerations.

Cost and Batch Efficiency

CVD is generally a more cost-effective process. The chamber can be packed densely with tools, and the gaseous nature of the process ensures all surfaces are coated uniformly, even in deep holes or complex internal geometries.

PVD is often more expensive due to a more complex loading process that requires fixtures to hold each tool, reducing batch density.

Substrate and Heat Sensitivity

PVD's low-temperature application makes it the only viable choice for heat-sensitive tool materials like high-speed steel (HSS) or for carbide grades where preserving maximum toughness is the priority.

Coating Integrity and Finish

PVD coatings tend to have a smoother surface finish and fewer microscopic voids than CVD coatings. This smooth finish further enhances lubricity and chip flow.

The thick nature of CVD coatings can slightly round the cutting edge, which is detrimental for applications requiring the absolute highest precision and sharpness, such as finishing or threading.

Making the Right Choice for Your Goal

Select your coating based on the primary challenge of your machining application.

- If your primary focus is high-volume roughing of steel and cast iron: CVD is your most reliable and cost-effective choice due to its superior thermal and abrasive wear resistance.

- If your primary focus is machining sticky materials (stainless, superalloys): PVD is the clear winner because its sharp, smooth edge prevents material buildup and reduces cutting forces.

- If your primary focus is interrupted cuts or maintaining tool toughness: PVD is the safer option as its low-temperature process preserves the substrate's inherent resistance to chipping.

- If your primary focus is finishing passes or high-precision work: PVD maintains the sharp cutting edge necessary for achieving tight tolerances and excellent surface finishes.

Ultimately, understanding the process behind the coating empowers you to select a tool that is not just coated, but optimized for your work.

Summary Table:

| Coating Type | Process Temperature | Coating Thickness | Key Strength | Best For |

|---|---|---|---|---|

| CVD (Chemical Vapor Deposition) | High (~1000°C / 1832°F) | Thick (5-20 microns) | Superior Abrasive & Thermal Wear Resistance | Roughing steel/cast iron, high-volume machining |

| PVD (Physical Vapor Deposition) | Low (<500°C / 932°F) | Thin (1-5 microns) | Enhanced Toughness & Edge Sharpness | Machining sticky materials (stainless, aluminum), finishing, interrupted cuts |

Optimize Your Machining Performance with the Right Coating

Selecting the correct coating is critical for maximizing tool life, improving part quality, and boosting productivity. The choice between CVD and PVD can significantly impact your results.

KINTEK specializes in precision lab equipment and consumables that support advanced material testing and analysis, helping you make data-driven decisions about tool coatings and processes.

Let our experts help you:

- Identify the ideal coating for your specific materials and machining operations.

- Source high-quality tools and consumables for your R&D or quality control labs.

- Improve your process efficiency and reduce costs.

Ready to enhance your machining capabilities? Contact our technical team today for a personalized consultation!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- Is diamond coating worth it? Maximize Component Life and Performance