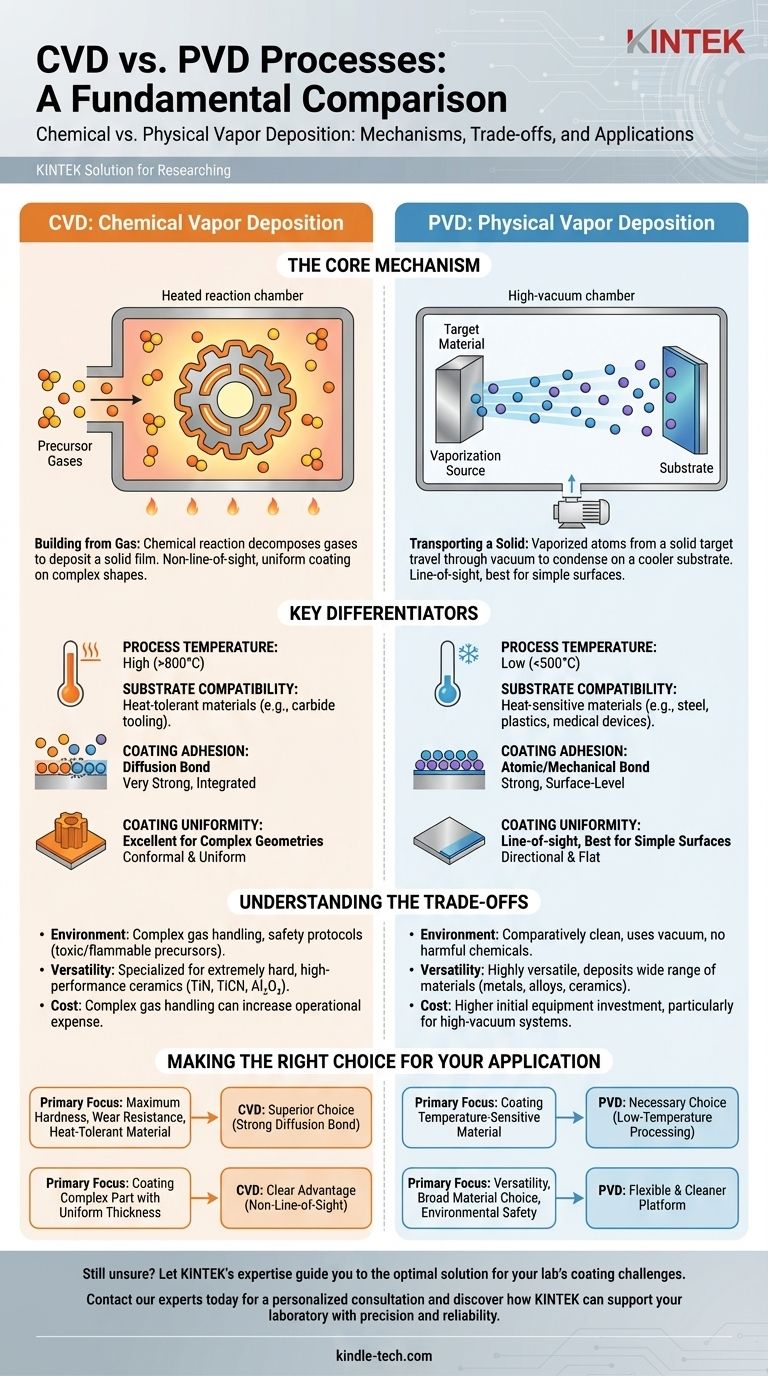

At a fundamental level, the difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in how the coating material arrives at and forms on a substrate. PVD is a physical process that transports a solid material through a vacuum to deposit it, atom by atom. In contrast, CVD is a chemical process that uses precursor gases which react on the substrate's surface to grow an entirely new material.

The choice between CVD and PVD is not about which process is "better," but which is appropriate for your specific application. CVD's high-temperature chemical bonding excels at creating extremely durable coatings, while PVD's lower-temperature physical process offers unmatched versatility for a wider range of materials.

The Core Mechanism: Chemical Reaction vs. Physical Transfer

Understanding how each process works at a molecular level is key to appreciating their distinct advantages and limitations.

How CVD Works: Building from Gas

In CVD, one or more volatile precursor gases are introduced into a reaction chamber containing the heated substrate. The high temperature triggers a chemical reaction among the gases, causing them to decompose and deposit a solid film onto the substrate.

This process is not line-of-sight. The gases envelop the entire part, allowing the coating to form uniformly on all exposed surfaces, even complex internal geometries.

How PVD Works: Transporting a Solid

PVD takes place in a high-vacuum chamber. A solid source material, known as a "target," is vaporized through methods like sputtering (bombarding it with ions) or thermal evaporation.

These vaporized atoms then travel in a straight line through the vacuum and condense onto the cooler substrate, forming a thin, dense film. This is fundamentally a line-of-sight process, similar to spray painting.

Key Differentiators and Their Impact

The differences in mechanism create critical distinctions in how the resulting coatings perform and which materials they can be applied to.

Process Temperature and Substrate Compatibility

This is often the most significant deciding factor. CVD requires very high temperatures (often >800°C) to drive the necessary chemical reactions. This limits its use to materials that can withstand this heat without warping, melting, or losing their temper, such as carbide tooling.

PVD, by contrast, is a low-temperature process (typically <500°C). This makes it safe to use on a vast range of materials, including tempered steels, alloys, plastics, and medical implants, without altering their fundamental properties.

Coating Adhesion and Durability

CVD creates a diffusion bond. The high heat causes atoms from the coating and the substrate to intermingle, forming an exceptionally strong, integrated bond. This results in outstanding adhesion and wear resistance.

PVD coatings form a strong atomic bond, but it is primarily a mechanical and surface-level bond. While very durable for most applications, it does not typically match the sheer adhesive strength of a high-temperature CVD diffusion bond.

Coating Uniformity and Geometry

Because the gases in CVD flow around the entire part, it produces a highly conformal and uniform coating, even on parts with complex shapes, holes, and internal surfaces.

PVD's line-of-sight nature means it excels at coating flat or simple exterior surfaces. Coating complex geometries uniformly requires sophisticated fixtures to rotate and reposition the part during the process.

Understanding the Trade-offs

Choosing a coating technology requires an objective look at the practical and operational trade-offs involved.

Operating Environment and Safety

CVD processes can be complex and often involve the use of toxic, flammable, or corrosive precursor gases. This necessitates significant investment in safety protocols and gas handling and abatement systems.

PVD is a comparatively clean and environmentally friendly process, as it operates in a vacuum and does not use harmful chemicals. While a risk of chamber failure exists, the day-to-day operational hazards are generally lower.

Automation and Versatility

PVD processes are typically more easily automated and can deposit a wider array of materials, including pure metals, alloys, and a vast range of ceramic compounds. This makes it highly versatile for both functional and decorative applications.

CVD is more specialized, focused on producing extremely hard, high-performance ceramic coatings like Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Aluminum Oxide (Al₂O₃).

Cost Considerations

The initial investment for specialized PVD equipment, particularly the high-vacuum systems, can be higher than for some CVD reactors. However, the overall cost-per-part can be influenced by factors like process complexity, safety requirements, and automation. CVD's complex gas handling can add significant operational expense.

Making the Right Choice for Your Application

Your final decision must be driven by your material and the performance you require from the coating.

- If your primary focus is maximum hardness and wear resistance on a heat-tolerant material: CVD is likely the superior choice due to its stronger diffusion bond.

- If your primary focus is coating a temperature-sensitive material like tempered steel, plastics, or medical devices: PVD is the necessary choice because of its low-temperature processing.

- If your primary focus is coating a complex part with uniform thickness on all surfaces: CVD's non-line-of-sight nature provides a clear advantage.

- If your primary focus is versatility, a wide choice of coating materials, or environmental safety: PVD often provides a more flexible and cleaner platform for a broader set of applications.

By understanding these core principles, you can confidently select the deposition technology that aligns perfectly with your engineering goals and material constraints.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

|---|---|---|

| Process Type | Chemical reaction from gases | Physical transfer of solid material |

| Temperature | High (>800°C) | Low (<500°C) |

| Coating Uniformity | Excellent for complex geometries | Line-of-sight, best for simple surfaces |

| Adhesion Strength | Diffusion bond (very strong) | Atomic/mechanical bond (strong) |

| Substrate Compatibility | Heat-tolerant materials (e.g., carbide) | Temperature-sensitive materials (e.g., steel, plastics) |

| Material Versatility | Specialized (e.g., TiN, TiCN, Al₂O₃) | Wide range (metals, alloys, ceramics) |

Still unsure which coating process is right for your lab's needs? Let KINTEK's expertise guide you. As specialists in lab equipment and consumables, we provide tailored solutions for your deposition requirements. Whether you need the high-temperature durability of CVD or the versatile, low-temperature capabilities of PVD, our team can help you select the optimal equipment to enhance your research and production outcomes.

Contact our experts today for a personalized consultation and discover how KINTEK can support your laboratory's coating challenges with precision and reliability.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films