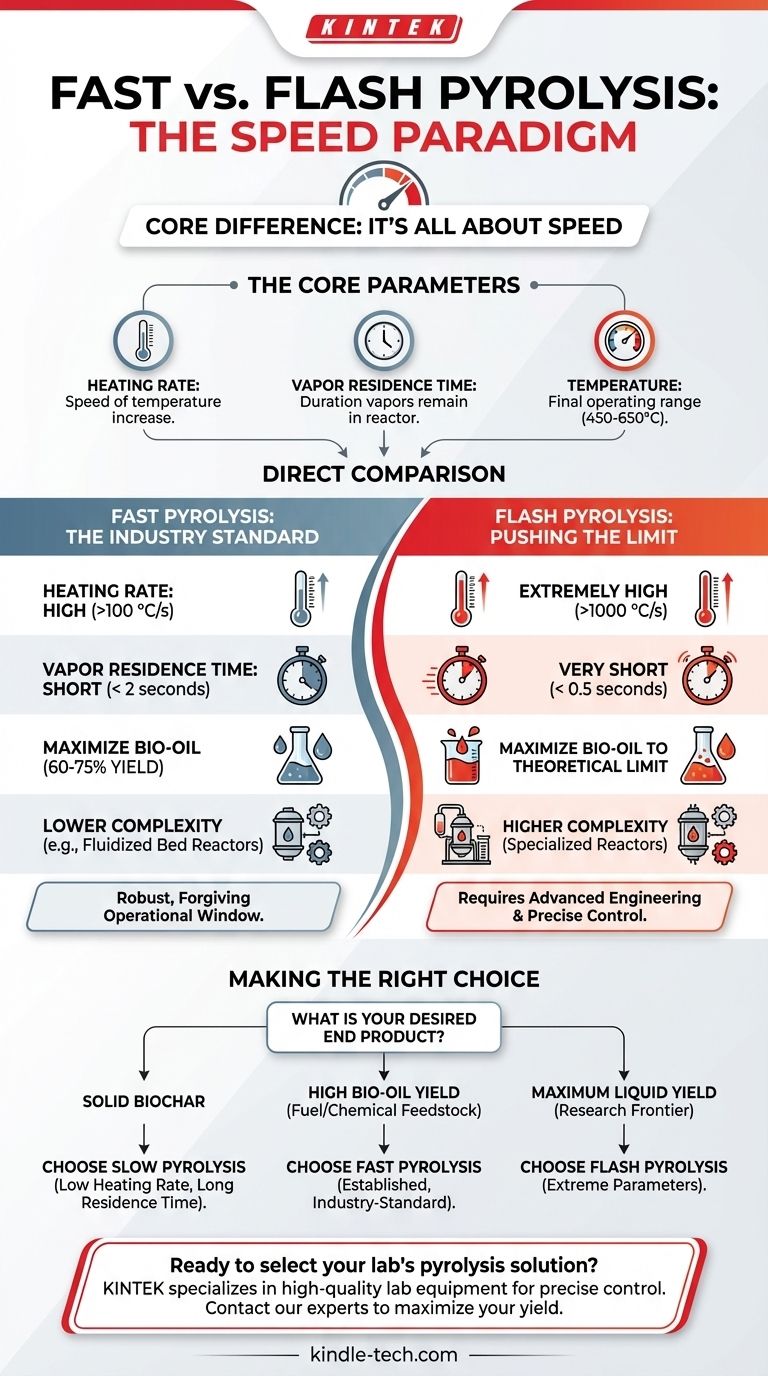

At its core, the difference between fast and flash pyrolysis comes down to speed. Both are processes designed to rapidly heat organic material in the absence of oxygen, but they operate on different time scales. The key distinguishing factors are the heating rate and the vapor residence time, which are significantly more extreme in flash pyrolysis.

The central takeaway is that flash pyrolysis is not a different process, but rather an extremely rapid and intense subset of fast pyrolysis. Both aim to maximize liquid bio-oil production, but flash pyrolysis pushes the operational parameters to their technical limits to achieve the highest possible liquid yield by minimizing secondary reactions.

The Core Parameters That Define Pyrolysis

To understand the difference, you must first grasp the three key variables that control the outcome of any pyrolysis process. The final products—bio-oil, biochar, or syngas—are a direct result of manipulating these conditions.

Heating Rate

This is the speed at which the temperature of the feedstock (e.g., biomass) is increased. A very high heating rate ensures the material breaks down quickly, favoring the formation of vapors that can be condensed into liquid bio-oil rather than forming a solid char structure.

Vapor Residence Time

This is the amount of time the hot pyrolysis vapors remain in the high-temperature reactor zone. Shorter residence times are crucial for preserving the liquid products. If vapors linger too long at high temperatures, they will "crack" or break down further into non-condensable, low-value gases.

Temperature

This is the final temperature the process operates at. For fast and flash pyrolysis, this is typically in the range of 450-650°C. Temperature influences which chemical bonds break, but heating rate and residence time determine what happens to the fragments afterward.

A Direct Comparison: Fast vs. Flash Pyrolysis

While they exist on a continuum, their typical operating windows and goals are distinct.

Fast Pyrolysis: The Standard for Bio-Oil

Fast pyrolysis is the most common method for producing high yields of bio-oil. It carefully balances process conditions to optimize liquid output.

- Heating Rate: High (typically >100 °C per second).

- Vapor Residence Time: Short (typically less than 2 seconds).

- Primary Goal: To maximize the production of liquid bio-oil, which typically reaches yields of 60-75% by weight.

Flash Pyrolysis: Pushing the Limit for Liquid Yield

Flash pyrolysis represents the extreme end of the rapid thermal processing spectrum. It requires more advanced engineering to achieve its aggressive conditions.

- Heating Rate: Extremely high (often >1000 °C per second).

- Vapor Residence Time: Very short (typically less than 0.5 seconds).

- Primary Goal: To achieve the absolute maximum theoretical yield of bio-oil by almost completely preventing secondary cracking of vapors into gas.

The essential difference is one of degree. By heating the material and removing the vapors almost instantaneously, flash pyrolysis effectively "freezes" the reaction at the initial decomposition stage, preserving the primary liquid compounds.

Understanding the Trade-offs

Choosing between these methods involves significant practical and engineering considerations. The pursuit of higher liquid yields comes with added complexity.

Engineering and Cost

Achieving the extreme heating rates of flash pyrolysis demands specialized and often more expensive reactor designs, such as entrained flow or ablative reactors. Standard fast pyrolysis can be accomplished with more common technologies like fluidized bed reactors.

Feedstock Preparation

Both processes require dry, finely ground feedstock for efficient heat transfer. However, flash pyrolysis is even more sensitive to particle size. The material must be incredibly small to allow for the near-instantaneous heating required.

Process Control

Maintaining the precise conditions of flash pyrolysis—especially the sub-second residence time—is a significant control challenge. Fast pyrolysis offers a slightly wider and more forgiving operational window, making it more robust for industrial-scale applications.

Making the Right Choice for Your Goal

The correct pyrolysis method is entirely dependent on your desired end product.

- If your primary focus is producing solid biochar for agriculture or carbon sequestration: Neither method is suitable; you need slow pyrolysis, which uses low heating rates and very long residence times.

- If your primary focus is generating high yields of bio-oil for use as a renewable fuel or chemical feedstock: Fast pyrolysis is the well-established, industry-standard approach.

- If your primary focus is research or a highly specialized application aimed at maximizing liquid yield above all else: Flash pyrolysis represents the technical frontier for bio-oil production.

Ultimately, choosing the right thermal process is about controlling reaction pathways to dictate your final product slate.

Summary Table:

| Parameter | Fast Pyrolysis | Flash Pyrolysis |

|---|---|---|

| Heating Rate | High (>100 °C/s) | Extremely High (>1000 °C/s) |

| Vapor Residence Time | Short (< 2 seconds) | Very Short (< 0.5 seconds) |

| Primary Goal | Maximize bio-oil yield (60-75%) | Maximize bio-oil yield to the theoretical limit |

| Complexity/Cost | Lower (e.g., fluidized bed reactors) | Higher (specialized reactors required) |

Ready to select the right pyrolysis process for your lab's bio-oil or biochar research? KINTEK specializes in high-quality lab equipment and consumables, including pyrolysis reactors and systems designed for precise temperature control and vapor residence times. Our experts can help you choose the right setup to maximize your yield and efficiency. Contact our team today to discuss your specific laboratory needs and how we can support your research goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time