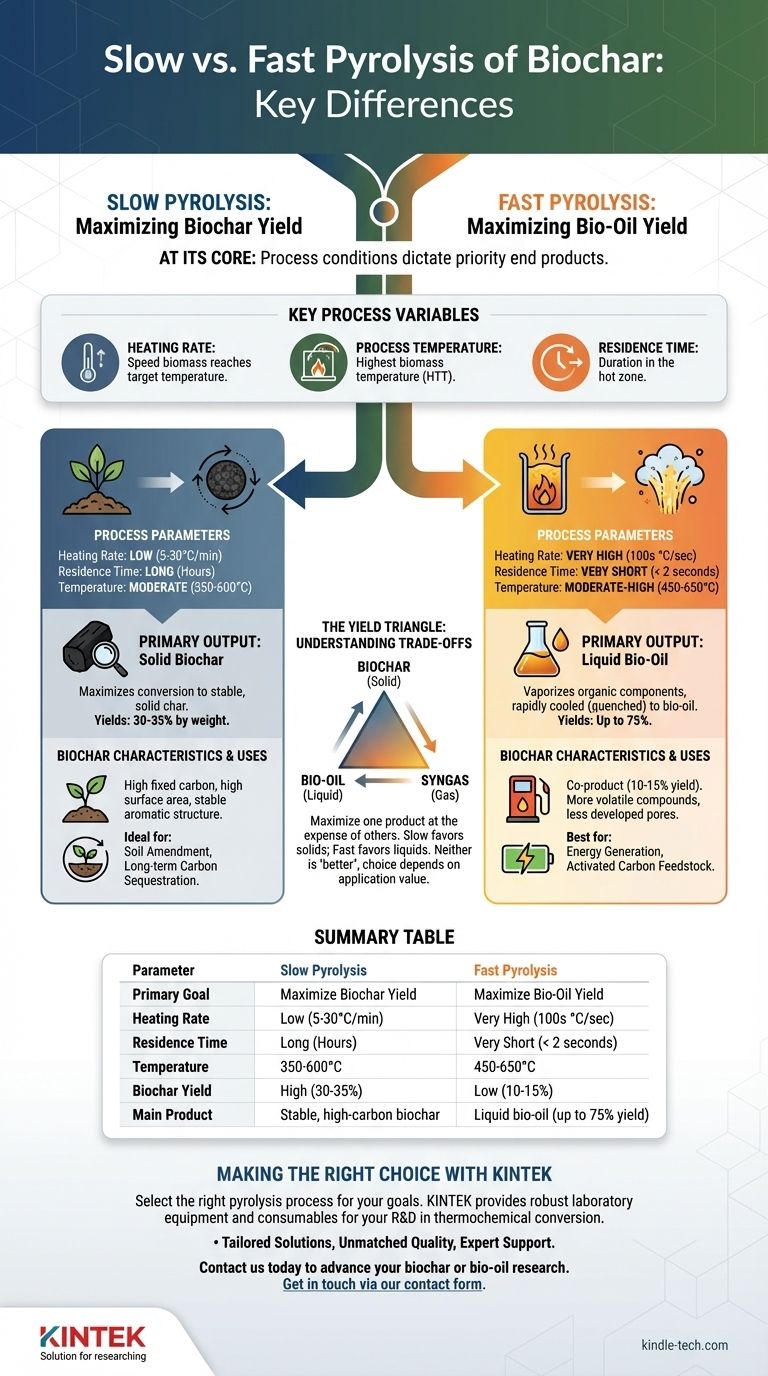

At its core, the difference between slow and fast pyrolysis lies in the process conditions, which are deliberately manipulated to prioritize different end products. Slow pyrolysis uses a low heating rate over a long period to maximize the yield of solid biochar. In contrast, fast pyrolysis uses an extremely high heating rate for mere seconds to maximize the output of liquid bio-oil, with biochar being a secondary product.

The choice between slow and fast pyrolysis is a strategic decision dictated by your primary goal. Slow pyrolysis is engineered to produce the maximum amount of solid biochar, while fast pyrolysis is optimized for the production of liquid biofuels.

Deconstructing the Key Process Variables

To understand the difference in outcomes, you must first understand the three critical variables that define any pyrolysis process. These parameters are intentionally adjusted to favor the creation of either solid, liquid, or gas products.

The Heating Rate

The heating rate is the speed at which the biomass feedstock is brought to its target temperature. This is one of the most significant distinguishing factors between slow and fast pyrolysis.

Process Temperature

This refers to the highest temperature the biomass reaches inside the reactor. As noted in research, the highest treatment temperature (HTT) has a profound influence on the final chemical and physical properties of the biochar.

Residence Time

Residence time is the duration the biomass (and its resulting vapors) spends inside the hot zone of the reactor. This can range from a few seconds to many hours.

Slow Pyrolysis: Maximizing Biochar Yield

Slow pyrolysis is the traditional method for making charcoal and is designed specifically to optimize the production of the solid carbon product.

The Process Parameters

This method is characterized by a low heating rate (e.g., 5-30°C per minute) and a long residence time, often lasting several hours. The peak temperatures are typically in the moderate range of 350-600°C.

The Primary Output: Solid Biochar

The slow, controlled heating allows the biomass to gradually break down and reorganize its carbon structure. This process maximizes the conversion of the original biomass into a stable, solid char, with yields often reaching 30-35% by weight.

Resulting Biochar Characteristics

Biochar from slow pyrolysis is generally high in fixed carbon, has a high surface area, and possesses a stable aromatic structure. These properties make it ideal for applications like soil amendment and long-term carbon sequestration.

Fast Pyrolysis: Maximizing Bio-Oil Yield

Fast pyrolysis is a more modern, intensive process developed with a different primary objective: producing liquid fuel.

The Process Parameters

This method uses an extremely rapid heating rate (often hundreds of degrees Celsius per second) and a very short vapor residence time (typically less than 2 seconds). Temperatures are often in the 450-650°C range.

The Primary Output: Liquid Bio-Oil

The intense, rapid heating vaporizes the organic components of the biomass before they can fully break down into solid char. These vapors are then rapidly cooled, or "quenched," to condense them into a liquid known as bio-oil or pyrolysis oil. Bio-oil yields can be as high as 75%.

Resulting Biochar Characteristics

In this process, biochar is a co-product, not the primary focus. The yield is consequently much lower, typically around 10-15%. The resulting char may also contain more volatile compounds and have a less developed pore structure compared to its slow pyrolysis counterpart.

Understanding the Trade-offs: Product vs. Process

Neither method is inherently "better"; they are simply optimized for different outcomes. Your choice depends entirely on which product holds the most value for your application.

The Yield Triangle

Think of pyrolysis as creating three products: solid biochar, liquid bio-oil, and non-condensable syngas. You can only adjust the process to maximize one or two of these at the expense of the others. Slow pyrolysis pushes the balance toward solids, while fast pyrolysis pushes it aggressively toward liquids.

Impact on Biochar Quality

Because slow pyrolysis is designed to create a stable solid, the resulting biochar is often considered higher "quality" for applications demanding stability and high carbon content, such as agriculture. The biochar from fast pyrolysis is still a valuable product but may be better suited for energy generation or as a feedstock for activated carbon.

Economic and Operational Factors

Fast pyrolysis systems are more technically complex and capital-intensive due to the need for rapid heating, fine feedstock grinding, and quick vapor quenching. Slow pyrolysis can be achieved with simpler, less expensive reactor designs, making it more accessible for smaller-scale operations focused on soil products.

Making the Right Choice for Your Goal

Your application dictates the correct production method. By understanding how process conditions influence product yields, you can select the pathway that directly serves your primary objective.

- If your primary focus is soil amendment or carbon sequestration: Choose slow pyrolysis to maximize the yield of stable, high-carbon biochar.

- If your primary focus is producing liquid biofuel (bio-oil): Choose fast pyrolysis, which is optimized for this purpose, and treat the biochar as a valuable co-product.

- If your primary focus is generating energy from gas: You would explore a third process, gasification, which operates at even higher temperatures to maximize syngas production.

Understanding these fundamental process differences empowers you to select the production pathway that aligns directly with your end-use application.

Summary Table:

| Parameter | Slow Pyrolysis | Fast Pyrolysis |

|---|---|---|

| Primary Goal | Maximize Biochar Yield | Maximize Bio-Oil Yield |

| Heating Rate | Low (5-30°C/min) | Very High (100s °C/sec) |

| Residence Time | Long (Hours) | Very Short (< 2 seconds) |

| Temperature | 350-600°C | 450-650°C |

| Biochar Yield | High (30-35%) | Low (10-15%) |

| Main Product | Stable, high-carbon biochar | Liquid bio-oil (up to 75% yield) |

Ready to select the right pyrolysis process for your biomass conversion goals?

The choice between slow and fast pyrolysis is critical for maximizing your desired product yield, whether it's high-quality biochar for soil amendment or liquid bio-oil for fuel. KINTEK specializes in providing robust laboratory equipment and consumables to support your R&D in thermochemical conversion processes.

Let our experts help you optimize your process:

- Tailored Solutions: Get equipment recommendations based on your specific biomass feedstock and target products.

- Unmatched Quality: Ensure reliable and repeatable results with our precision lab reactors and furnaces.

- Expert Support: Leverage our technical knowledge to scale your process from lab to pilot.

Contact us today to discuss how KINTEK's solutions can advance your biochar or bio-oil research. Get in touch via our contact form to start the conversation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output