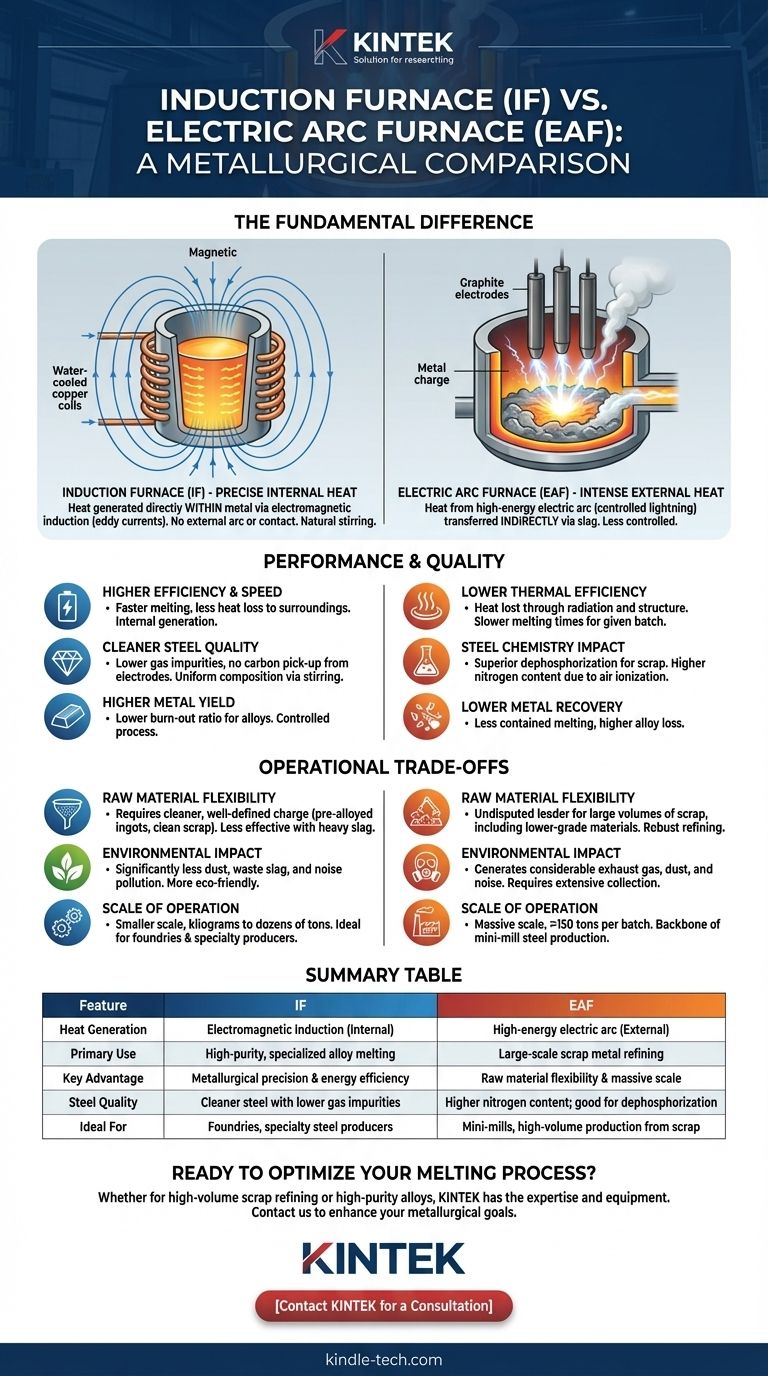

At their core, an electric arc furnace (EAF) and an induction furnace (IF) differ fundamentally in how they generate heat to melt metal. An arc furnace uses a high-energy electric arc—essentially a controlled lightning strike—that jumps from graphite electrodes to the metal charge. In contrast, an induction furnace uses a powerful magnetic field to generate heat directly within the metal itself, without any external contact or arc.

The choice between these two technologies is a strategic decision between raw refining power and controlled metallurgical precision. Electric Arc Furnaces are robust workhorses for large-scale scrap metal recycling, while Induction Furnaces are precision tools for producing clean, specialized alloys with high efficiency.

The Fundamental Difference: How Heat is Generated

The method of heating is the single most important distinction, as it dictates the efficiency, controllability, and environmental impact of each furnace.

The Electric Arc Furnace (EAF): Intense External Heat

An EAF melts metal using an extremely hot electric arc. This arc forms between graphite electrodes and the metallic charge inside the furnace.

The process is a form of indirect heating. The intense heat of the arc is transferred to the metal, primarily through a layer of slag, to achieve melting. This is a powerful but less-controlled method, ideal for breaking down large, unrefined materials.

The Induction Furnace (IF): Precise Internal Heat

An induction furnace operates on the principle of electromagnetic induction. A water-cooled copper coil surrounds the crucible containing the metal, and a powerful alternating current is passed through it.

This creates a fluctuating magnetic field that induces strong electrical currents (eddy currents) directly within the metal charge. The metal's own electrical resistance causes it to heat up rapidly from the inside out. This process also creates a natural electromagnetic stirring action, ensuring the molten bath is homogenous.

Comparing Performance and Steel Quality

The differences in heating mechanisms lead to significant variations in efficiency, final product quality, and operational characteristics.

Thermal Efficiency and Speed

An induction furnace is significantly more efficient. Because heat is generated internally, less energy is lost to the furnace walls, cover, or surrounding environment.

Arc furnaces have lower thermal efficiency because a great deal of heat radiates from the open arc and is lost through the furnace structure. Consequently, induction furnaces can often achieve faster melting times for a given batch size.

Impact on Metal Chemistry

The furnace type directly influences the final chemistry of the steel.

Arc furnaces are superior for dephosphorization, a critical step in refining lower-quality scrap metal. However, the high-temperature arc ionizes nitrogen from the air, resulting in a higher nitrogen content in the final steel.

Induction furnaces produce cleaner steel with lower gas impurities. They do not use graphite electrodes, which eliminates the risk of unintentional carbon pick-up—a critical factor for producing low-carbon and stainless steels. The electromagnetic stirring ensures a highly uniform chemical composition and temperature.

Metal Yield and Alloy Recovery

Induction furnaces offer a higher metal recovery rate. The more controlled and contained melting process results in a lower burn-out ratio for expensive alloy elements added to the melt.

Understanding the Trade-offs: Operational & Environmental

Choosing a furnace involves balancing performance with practical operational and environmental constraints.

Raw Material Flexibility

The EAF is the undisputed leader in raw material flexibility. Its aggressive melting process is perfectly suited for large volumes of scrap steel, including lower-grade or contaminated materials. It is fundamentally a refining vessel.

Induction furnaces require a cleaner, more well-defined charge. They are less effective at handling heavy slag or removing impurities, making them better suited for melting pre-alloyed ingots or clean, certified scrap.

Environmental Impact

The induction furnace is the more environmentally friendly option. It produces significantly less dust, waste slag, and noise pollution.

The EAF process, with its open arc and use of carbon electrodes, generates considerable exhaust gas, dust (requiring extensive collection systems), and acoustic noise.

Scale of Operation

EAFs are built for massive scale, with capacities that can exceed 150 tons per batch. They are the backbone of "mini-mill" steel production worldwide.

Induction furnaces typically operate on a smaller scale, from a few kilograms to several dozen tons, making them ideal for foundries and specialty steel producers.

Making the Right Choice for Your Application

The best furnace is the one that aligns with your specific production goals, raw material supply, and quality requirements.

- If your primary focus is large-scale production from scrap steel: The robust refining capability, raw material flexibility, and massive scale of an Electric Arc Furnace make it the industry standard.

- If your primary focus is producing high-purity, specialized alloys or clean steel: The metallurgical precision, low contamination, and inherent stirring of an Induction Furnace are superior.

- If your primary focus is energy efficiency and environmental compliance: An Induction Furnace offers a clear advantage with lower emissions, less waste, and higher thermal efficiency.

Ultimately, your decision rests on a clear understanding of whether your goal is high-volume refining or high-precision melting.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Induction Furnace (IF) |

|---|---|---|

| Heat Generation | High-energy electric arc (external) | Electromagnetic induction (internal) |

| Primary Use | Large-scale scrap metal refining | High-purity, specialized alloy melting |

| Key Advantage | Raw material flexibility & massive scale | Metallurgical precision & energy efficiency |

| Steel Quality | Higher nitrogen content; good for dephosphorization | Cleaner steel with lower gas impurities |

| Ideal For | Mini-mills, high-volume production from scrap | Foundries, specialty steel producers |

Ready to Optimize Your Melting Process?

Choosing the right furnace technology is critical to the efficiency, quality, and cost-effectiveness of your operation. Whether your goal is high-volume scrap refining or producing high-purity alloys, KINTEK has the expertise and equipment to meet your laboratory and production needs.

Contact us today to discuss how our solutions can enhance your process. Our specialists will help you select the perfect equipment to achieve your metallurgical and production goals.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- What are the core advantages of using a vacuum hot pressing furnace for Cu/WC composites? Superior Density & Bonding

- Why is using a vacuum hot press for diamond composites preferred? Achieve Maximum Thermal Conductivity

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- Why is a vacuum hot press furnace required for TiAl-based composite preforms? Ensure Purity and Density