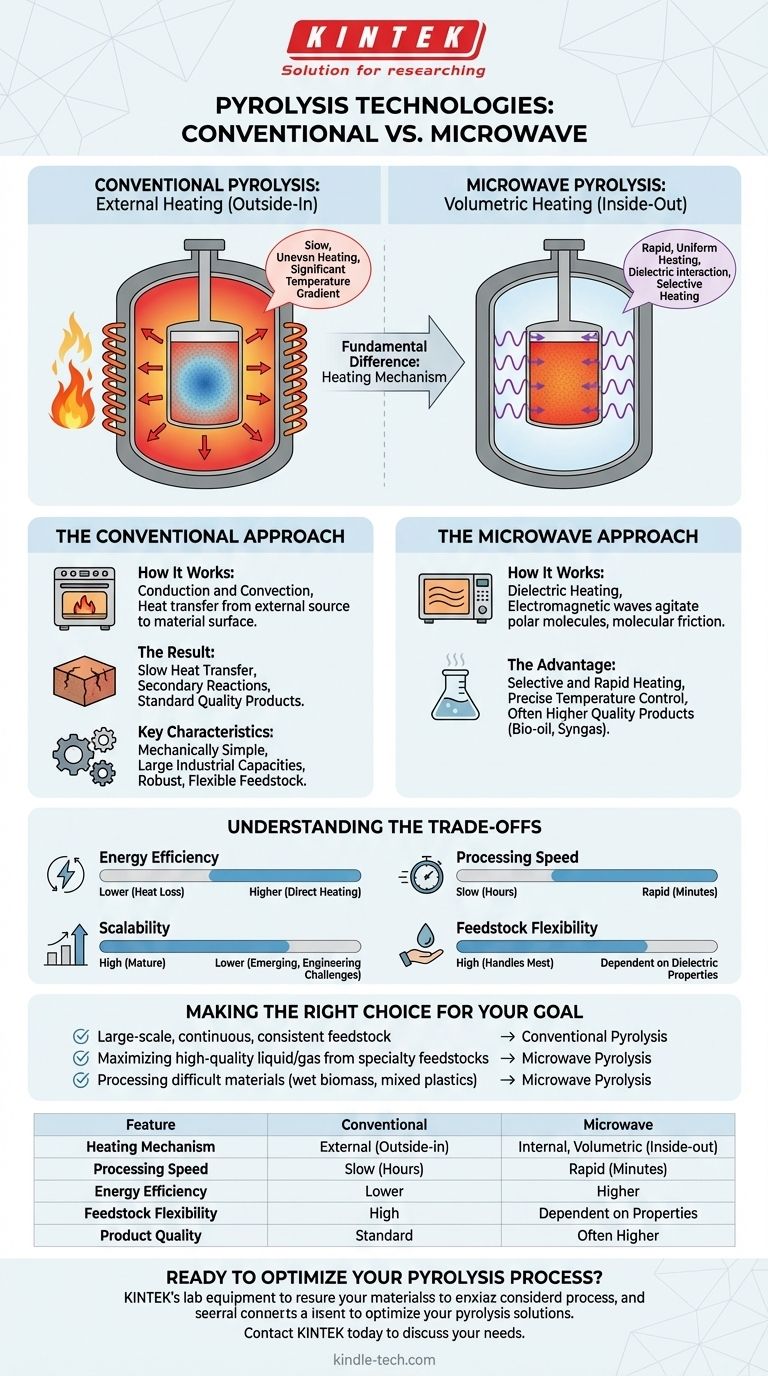

The fundamental difference between microwave pyrolysis and conventional pyrolysis is the heating mechanism. Conventional pyrolysis transfers heat from an external source to the material's surface, heating it from the outside-in. In contrast, microwave pyrolysis uses electromagnetic waves to heat the material directly at a molecular level, creating heat from the inside-out.

This distinction is not merely technical; it dictates the entire process. The method of heating directly impacts processing speed, energy efficiency, temperature control, and the quality of the final products (bio-oil, syngas, and char), making each approach suitable for different goals and feedstocks.

The Conventional Approach: External Heating

Conventional pyrolysis is the most established and widely used method. Think of it like a standard kitchen oven—it heats the outside of the container, and that heat must slowly travel into the material.

How It Works: Conduction and Convection

The process relies on traditional heat transfer methods. A reactor vessel is heated externally by burning fuel or using electric resistance heaters.

This heat is transferred to the feedstock through conduction (direct contact with hot surfaces) and convection (hot gases).

The Result: Slow Heat Transfer and Temperature Gradients

Because heat must penetrate from the surface to the core, a significant temperature gradient forms. The outside of the material is much hotter than the inside.

This slow and uneven heating can lead to secondary reactions, where the desired vapors crack into less valuable gases and char as they pass through the hotter outer layers.

Key Characteristics

Conventional systems are mechanically simple and have been scaled to large industrial capacities. They are robust and can handle a wide variety of feedstocks without much pre-treatment.

The Microwave Approach: Volumetric Heating

Microwave pyrolysis is a more advanced technology that leverages a fundamentally different energy delivery system. It works on the same principle as a microwave oven but is applied in a controlled, oxygen-free environment.

How It Works: Dielectric Heating

Microwaves are a form of electromagnetic radiation that directly interacts with and agitates polar molecules within the feedstock. This molecular friction generates heat rapidly and uniformly throughout the material's volume.

This is known as volumetric heating. Instead of waiting for heat to travel from the surface, the core of the material heats up just as quickly as the outside.

The Advantage: Selective and Rapid Heating

A key benefit is selective heating. Microwaves preferentially heat materials that absorb them well (like carbon or water) while passing through materials that are transparent to them (like certain plastics or ceramics).

This allows for incredibly rapid heating rates and precise temperature control, minimizing unwanted secondary reactions and often resulting in higher quality bio-oil or syngas.

Understanding the Trade-offs

Neither method is universally superior. The optimal choice depends entirely on the specific application, feedstock, and desired outcome.

Energy Efficiency and Speed

Conventional pyrolysis often suffers from significant heat loss to the environment and the reactor vessel itself. The process is slow, often taking hours.

Microwave pyrolysis can be much more energy-efficient because it heats only the target material, not the entire reactor. This results in processing times measured in minutes, not hours.

Scalability and Maturity

Conventional pyrolysis is a mature, well-understood technology that has been proven at a massive industrial scale. The equipment is robust and relatively straightforward to operate and maintain.

Microwave pyrolysis is a newer technology. Scaling it up presents engineering challenges, such as ensuring uniform microwave distribution in large reactors and managing the risk of electrical arcing.

Feedstock Flexibility

Conventional systems are highly flexible and can process almost any organic material. Their performance is less dependent on the material's chemical or physical properties.

Microwave pyrolysis depends on the feedstock's dielectric properties—its ability to absorb microwave energy. Poorly absorbing materials may need to be mixed with a highly absorbent substance, like biochar, to initiate the process effectively.

Product Quality and Yield

The slow heating of conventional methods can degrade valuable liquid products (bio-oil) into less desirable char and gas.

The rapid, uniform heating in microwave pyrolysis often maximizes the yield of high-quality bio-oil and syngas by quickly removing vapors from the hot zone before they can break down.

Making the Right Choice for Your Goal

To select the appropriate technology, you must first define your primary objective.

- If your primary focus is large-scale, continuous processing of a consistent feedstock: Conventional pyrolysis offers the most mature, reliable, and economically proven solution.

- If your primary focus is maximizing high-quality liquid or gas yields from specialty feedstocks: Microwave pyrolysis provides superior control, speed, and product quality.

- If your primary focus is processing difficult materials like wet biomass or mixed plastics: Microwave pyrolysis's selective heating can offer significant energy savings and efficiency gains.

By understanding that the core difference is how heat is delivered, you can choose the technology that best aligns with your material, scale, and economic goals.

Summary Table:

| Feature | Conventional Pyrolysis | Microwave Pyrolysis |

|---|---|---|

| Heating Mechanism | External heating (outside-in) | Internal, volumetric heating (inside-out) |

| Processing Speed | Slow (hours) | Rapid (minutes) |

| Energy Efficiency | Lower (heat loss to reactor) | Higher (direct material heating) |

| Scalability | High (mature, large-scale) | Lower (emerging technology) |

| Feedstock Flexibility | High (handles most materials) | Dependent on dielectric properties |

| Typical Product Quality | Standard | Often higher (less degradation) |

Ready to optimize your pyrolysis process? The right lab equipment is critical for achieving your goals in bio-oil, syngas, or char production. At KINTEK, we specialize in providing robust and precise lab equipment and consumables to support your research and development in thermal conversion technologies. Whether you're scaling up a conventional system or exploring the advantages of microwave pyrolysis, our experts can help you select the right tools. Contact our team today to discuss your specific laboratory needs and discover how KINTEK can enhance your efficiency and results.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products