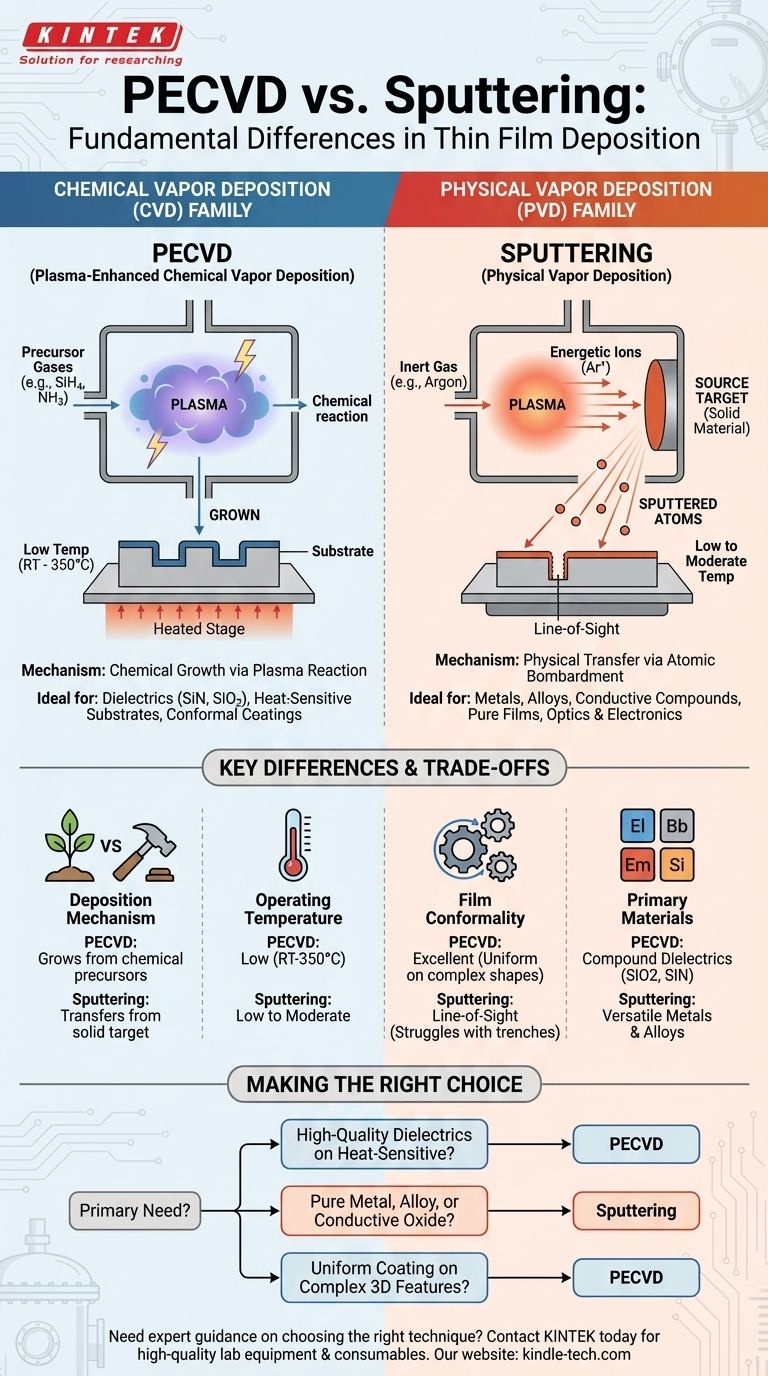

At their core, PECVD and sputtering are fundamentally different methods for creating a thin film. Sputtering is a physical process that uses energetic ions to physically knock atoms from a source target onto a substrate. In contrast, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a chemical process that uses plasma to drive chemical reactions from precursor gases, allowing a new material to "grow" on the substrate surface at low temperatures.

The most critical distinction is how the film material arrives at the substrate. Sputtering is a physical transfer—like a nanoscale sandblaster—while PECVD is a chemical reaction—like precisely controlled condensation. This single difference dictates the materials you can use, the properties of the final film, and the substrates you can coat.

The Fundamental Divide: Chemical vs. Physical Deposition

To understand the difference between these two techniques, you must first recognize that they belong to two separate families of thin-film deposition: Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD).

Chemical Vapor Deposition (CVD) Explained

In a traditional CVD process, precursor gases are introduced into a chamber and heated to very high temperatures (often 600–800°C). This thermal energy breaks the chemical bonds in the gases, initiating a reaction that deposits a solid film onto the substrate.

How PECVD Refines the Process

PECVD is a modern variant of CVD designed to overcome the high-temperature requirement. Instead of relying solely on heat, it introduces an energy-rich plasma into the chamber.

This plasma provides the necessary energy to break down the precursor gases and drive the chemical reaction, allowing for high-quality film deposition at much lower temperatures (typically room temperature to 350°C). This makes it indispensable for coating heat-sensitive materials, such as integrated circuits in their final manufacturing stages.

Physical Vapor Deposition (PVD) Explained

PVD techniques do not involve chemical reactions. Instead, they work by physically moving material from a solid source (called a "target") to the substrate in a vacuum. This can be done by heating the source until it evaporates or, in the case of sputtering, by bombarding it with ions.

How Sputtering Works

Sputtering is a highly controlled PVD process. It begins by introducing an inert gas, typically Argon, into a vacuum chamber and creating a plasma. The positively charged Argon ions are then accelerated by an electric field and directed at the target.

When these ions collide with the target, they physically knock off, or "sputter," atoms of the target material. These ejected atoms then travel through the vacuum and deposit onto the substrate, building up the thin film atom by atom.

Key Differences in Application and Outcome

The mechanical and chemical differences between PECVD and sputtering lead to significant variations in their use and the resulting films.

Deposition Mechanism: Growing vs. Bombarding

PECVD grows a film from chemical precursors. This means the resulting material (e.g., silicon nitride) can be different from the starting gases (e.g., silane and ammonia).

Sputtering transfers a film via atomic bombardment. The film is composed of the same material as the target, making it ideal for depositing pure metals, alloys, and specific compounds with high fidelity.

Operating Temperature

This is a critical differentiator. PECVD is a low-temperature process by design, making it perfect for substrates that cannot withstand the high heat of traditional CVD. While sputtering is also considered a low-temperature process, PECVD was specifically developed to deposit materials like high-quality dielectrics onto finished electronic components without damaging them.

Film Properties and Quality

PECVD is renowned for producing dense, pinhole-free, and conformal films. Because the deposition is driven by a chemical reaction that can occur on all exposed surfaces, it is excellent at uniformly coating complex shapes with high "step coverage."

Sputtering deposits material in a "line-of-sight" fashion. While it produces very dense films with excellent adhesion, it can struggle to uniformly coat intricate topographies with deep trenches or sharp corners.

Material Versatility

Sputtering is exceptionally versatile for depositing a vast range of materials, including nearly any metal, alloy, or electrically conductive compound. If you have a solid target of the material, you can likely sputter it.

PECVD is specialized for depositing compound materials, particularly dielectrics like silicon dioxide (SiO2) and silicon nitride (SiN), which are critical for insulating layers in the semiconductor industry.

Understanding the Trade-offs

Neither method is universally superior; the choice depends entirely on the goal.

The Challenge of Conformal Coatings

Sputtering's line-of-sight nature is a limitation for 3D structures. The top surfaces receive more material than the sidewalls, a phenomenon known as shadowing. PECVD's chemical nature gives it a distinct advantage here, providing much more uniform coverage over complex features.

Managing Film Stress

The energetic ion bombardment in sputtering can induce significant compressive stress in the deposited film. While this often improves density, excessive stress can cause the film to crack or delaminate. PECVD film stress is controlled by different parameters (plasma power, gas flow) and must also be carefully managed.

Complexity and Contamination

Because PECVD uses reactive gases, byproducts can be incorporated into the film. For instance, hydrogen from precursor gases is often present in PECVD films, which can affect optical or electrical properties. Sputtering, using an inert gas, can produce films of extremely high purity, limited only by the purity of the target material itself.

Making the Right Choice for Your Application

Your decision should be guided by your material needs, substrate limitations, and the geometry of the part you are coating.

- If your primary focus is depositing high-quality dielectrics (SiO2, SiN) on a temperature-sensitive substrate: PECVD is the clear choice due to its low-temperature operation and excellent film quality.

- If your primary focus is depositing a pure metal, complex alloy, or conductive oxide for optics or electronics: Sputtering offers unmatched material versatility, purity, and control.

- If your primary focus is achieving a uniform coating on a component with complex 3D features: PECVD generally provides superior conformality and step coverage compared to line-of-sight sputtering.

Ultimately, choosing the right technique requires a clear understanding of your end goal and the trade-offs between a chemical growth process and a physical transfer process.

Summary Table:

| Feature | PECVD (Plasma-Enhanced Chemical Vapor Deposition) | Sputtering (Physical Vapor Deposition) |

|---|---|---|

| Core Mechanism | Chemical reaction (film growth) | Physical transfer (atomic bombardment) |

| Operating Temperature | Low (Room Temp - 350°C) | Low (Room Temp - Moderate) |

| Film Conformality | Excellent (uniform on complex shapes) | Line-of-sight (can struggle with trenches) |

| Primary Materials | Dielectrics (e.g., SiN, SiO2) | Metals, Alloys, Conductive Compounds |

| Ideal For | Heat-sensitive substrates, ICs, conformal coatings | Pure materials, optics, electronics, high-purity films |

Need expert guidance on choosing the right deposition technique for your application?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your thin-film deposition needs. Whether you require the low-temperature, conformal capabilities of PECVD or the material versatility and purity of sputtering, our experts can help you select the perfect solution for your laboratory.

Contact us today to discuss your specific requirements and discover how KINTEK can enhance your research and production processes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained