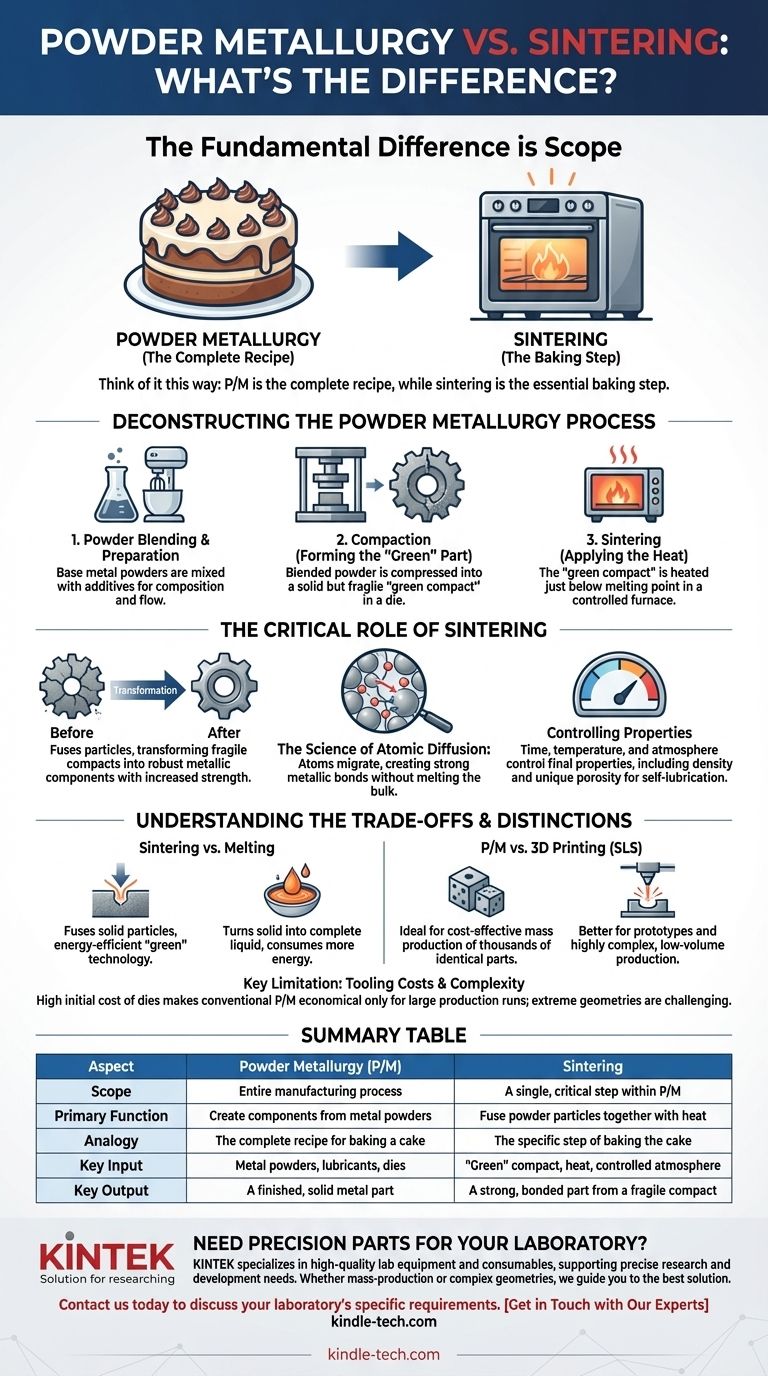

The fundamental difference is one of scope: sintering is not a separate process from powder metallurgy, but rather a critical step within the broader powder metallurgy manufacturing method. Powder metallurgy is the entire industrial process of creating components from metal powders, which includes blending, compacting the powder into a shape, and finally, sintering it with heat to create a solid, functional part.

Think of it this way: Powder metallurgy is the complete recipe for baking a cake, while sintering is the specific and essential step of putting that cake in the oven. You cannot have the finished cake without the baking step, and the baking step only makes sense in the context of the overall recipe.

Deconstructing the Powder Metallurgy Process

To fully grasp the relationship, it's essential to understand the distinct stages of the powder metallurgy (P/M) process. It is a precise, multi-step method for producing net-shape or near-net-shape parts.

Step 1: Powder Blending and Preparation

Before any shaping occurs, the base metal powders are carefully mixed. This step allows for the addition of alloying elements or lubricants to achieve the desired chemical composition and flow characteristics for the subsequent steps.

Step 2: Compaction (Forming the "Green" Part)

The blended powder is fed into a high-precision die and compressed under immense pressure. This action forces the powder particles into close contact, forming a solid but fragile part with the desired shape. This pre-sintered component is known as a "green compact."

Step 3: Sintering (Applying the Heat)

This is the core transformation. The green compact is placed in a controlled-atmosphere furnace and heated to a temperature just below the melting point of the primary metal. This thermal energy causes the individual metal particles to fuse together through atomic diffusion.

This process is analogous to how several ice cubes in a glass of water will fuse together at their contact points over time, even though the water is well above freezing. The result is a single, solid mass with significantly enhanced strength and structural integrity.

The Critical Role of Sintering

Sintering is not merely a heating step; it is where the material's final properties are fundamentally defined. Without it, the powder metallurgy process would only produce a brittle, chalk-like compact.

From Fragile Compact to Structural Component

The primary purpose of sintering is to bond the metal particles, transforming the fragile green compact into a robust metallic component. This bonding process dramatically increases the part's strength, hardness, and ductility.

The Science of Atomic Diffusion

Sintering works by promoting atomic diffusion across the boundaries of the tightly packed powder particles. Atoms migrate between particles, creating strong, permanent metallic bonds that eliminate the voids between them and solidify the structure, all without melting the bulk material.

Controlling Key Material Properties

The time, temperature, and atmosphere of the sintering cycle are carefully controlled to determine the final properties of the part. This includes its final density and porosity. This controlled porosity is a unique advantage of P/M, allowing for the creation of self-lubricating bearings that hold oil within their structure.

Understanding the Trade-offs and Distinctions

The tight relationship between these terms can lead to confusion, especially when other technologies use similar principles.

Key Distinction: Sintering vs. Melting

Sintering fuses solid particles together; melting turns a solid into a complete liquid. Because P/M avoids full melting, it is a highly energy-efficient or "green" technology compared to casting, where large volumes of metal must be melted.

Key Distinction: Powder Metallurgy vs. 3D Printing (SLS)

Additive manufacturing methods like Selective Laser Sintering (SLS) also use the principle of sintering. However, SLS uses a laser to sinter powder layer-by-layer to build a part without a mold.

Conventional powder metallurgy, by contrast, uses a die to compact the powder and is far more cost-effective for the mass production of thousands or millions of identical parts. SLS is better suited for prototypes and highly complex, low-volume production.

Key Limitation: Tooling Costs and Complexity

The primary trade-off of conventional powder metallurgy is the high initial cost of creating the compaction dies. This makes the process economical only for large production runs. While P/M can create parts with medium complexity, extremely intricate geometries can be challenging to achieve with this method.

Making the Right Choice for Your Goal

Understanding this relationship allows you to select the appropriate manufacturing process based on your specific project requirements.

- If your primary focus is mass production of small, moderately complex metal parts: Powder metallurgy is an extremely cost-effective and repeatable choice due to its high speed and low material waste.

- If your primary focus is creating self-lubricating components: The controlled porosity achieved through powder metallurgy and its sintering step is a unique and powerful advantage not easily replicated by other methods.

- If your primary focus is creating a one-off prototype or a highly complex geometry: A process like Selective Laser Sintering (SLS) is likely the better choice, even though it also relies on the fundamental principle of sintering.

By recognizing sintering as a key stage within the larger powder metallurgy framework, you can better evaluate its strengths and limitations for your engineering challenge.

Summary Table:

| Aspect | Powder Metallurgy (P/M) | Sintering |

|---|---|---|

| Scope | The entire manufacturing process | A single, critical step within P/M |

| Primary Function | Create components from metal powders | Fuse powder particles together with heat |

| Analogy | The complete recipe for baking a cake | The specific step of baking the cake |

| Key Input | Metal powders, lubricants, dies | "Green" compact, heat, controlled atmosphere |

| Key Output | A finished, solid metal part | A strong, bonded part from a fragile compact |

Need Precision Parts for Your Laboratory?

Understanding the right manufacturing process is key to achieving the desired material properties for your lab equipment. KINTEK specializes in providing high-quality lab equipment and consumables, supporting the precise needs of research and development.

Whether your project requires the mass-production efficiency of powder metallurgy or the complex geometries possible with other methods, our expertise can guide you to the best solution.

Contact us today to discuss how we can support your laboratory's specific requirements with reliable equipment and expert consultation.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the primary function of a vacuum hot pressing sintering furnace? Expert Guide for Ti-22Al-25Nb Fabrication

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al

- What technical advantages does a vacuum hot pressing sintering furnace provide? Enhance Fe-Ni/Zr2P2WO12 Composite Density

- How does a vacuum hot pressing sintering furnace facilitate TiBw/TA15 synthesis? Achieve 100% Dense Titanium Composites

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics