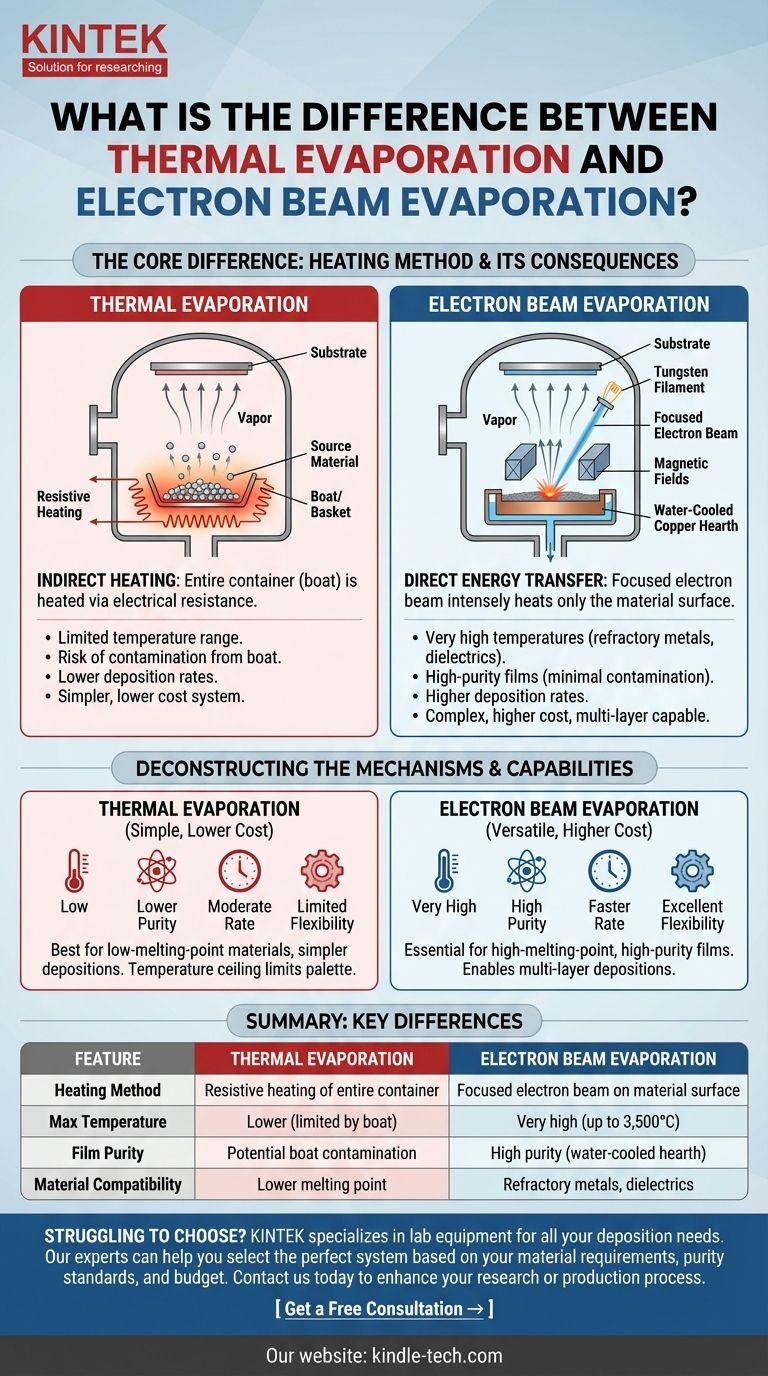

At its core, the difference between thermal evaporation and electron beam (e-beam) evaporation is the method used to heat the source material into a vapor. Thermal evaporation uses electrical resistance to heat an entire container, or "boat," which in turn heats the material. In contrast, e-beam evaporation uses a focused, high-energy beam of electrons to directly and intensely heat only the surface of the material itself.

The choice between these two methods is not about the heating mechanism in isolation, but about its consequences. E-beam evaporation's direct, intense heating unlocks the ability to deposit high-purity films from high-melting-point materials, a task where thermal evaporation is fundamentally limited.

Deconstructing the Heating Mechanisms

To understand the practical differences, we must first visualize how each process works inside the vacuum chamber. Both are forms of Physical Vapor Deposition (PVD), but their approach to generating vapor is fundamentally distinct.

Thermal (Resistive) Evaporation: Indirect Heating

In thermal evaporation, the source material (often in pellet form) is placed into a small, conductive crucible, commonly called a "boat" or "basket."

An electric current is passed through this boat. Due to its electrical resistance, the boat heats up rapidly, much like the coil in a toaster.

This heat is then transferred to the source material, causing it to melt and eventually evaporate. The vaporized atoms travel upward through the vacuum, coating the substrate.

Electron Beam Evaporation: Direct Energy Transfer

E-beam evaporation uses a much more targeted and powerful method. A tungsten filament is heated to generate a stream of high-energy electrons.

Magnetic fields are used to steer and focus these electrons into a tight beam, which is directed onto the surface of the source material resting in a water-cooled copper hearth.

The kinetic energy of the electrons is converted to thermal energy líderes upon impact, causing a small spot on the material's surface to reach extremely high temperatures and evaporate.

Key Differences in Performance and Capability

The difference in heating method leads to significant divergence in what each technique can achieve. The decision to use one over the other is driven by material requirements, purity, and process complexity.

Material Compatibility and Temperature

E-beam's ability to focus immense energy allows it to reach temperatures far beyond the limits of thermal evaporation.

This makes e-beam the necessary choice for depositing high-melting-point materials, such as refractory metals (tungsten, tantalum) and dielectric compounds (silicon dioxide). Thermal evaporation simply cannot get hot enough.

Film Purity and Contamination

E-beam evaporation generally produces purer thin films. Because the electron beam heats only the source material and the hearth is water-cooled, contamination from the container is virtually eliminated.

In thermal evaporation, the boat itself is superheated along with the material. This creates a risk that atoms from the boat will also evaporate and become incorporated into the film as impurities.

Deposition Rate and Control

The intense and efficient energy transfer of an electron beam typically allows for higher deposition rates compared to thermal evaporation.

This can be a critical factor in manufacturing environments where throughput is a primary concern.

Process Flexibility

E-beam systems are more versatile. They can be equipped with multi-pocket carousels that hold several different source materials.

This allows for the deposition of multiple, distinct layers in a single vacuum cycle, which is essential for creating complex optical coatings or electronic device structures.

Understanding the Trade-offs

While e-beam evaporation is more capable, it is not universally superior. The choice involves clear trade-offs in complexity and cost.

The Limitation of Thermal Evaporation

The primary drawback of thermal evaporation is its temperature ceiling. This strictly limits the palette of materials you can work with.

It is best suited for simpler depositions of materials with lower melting points, where its simplicity and lower cost are distinct advantages.

The Cost of E-Beam's Versatility

E-beam systems are significantly more complex and expensive to purchase and maintain.

The high-voltage power supplies, magnetic beam-steering components, and water-cooling systems add layers of operational complexity that are unnecessary for simpler deposition tasks.

Making the Right Choice for Your Application

Selecting the correct method requires matching your goal to the technology's core strengths.

- If your primary focus is simplicity and cost for lower-temperature materials: Thermal evaporation is the clear and effective choice.

- If your primary focus is depositing high-melting-point materials like refractory metals or dielectrics: Electron beam evaporation is the only viable option of the two.

- If your primary focus is achieving the highest possible film purity: Electron beam evaporation's localized heating and use of a cooled hearth give it a significant advantage.

- If your primary focus is process flexibility for multi-layer depositions: E-beam systems with multi-pocket sources are specifically designed for this purpose.

By understanding that the heating method dictates material compatibility and film purity, you can confidently select the right tool for your specific deposition goal.

Summary Table:

| Feature | Thermal Evaporation | Electron Beam Evaporation |

|---|---|---|

| Heating Method | Resistive heating of entire container | Focused electron beam on material surface |

| Max Temperature | Lower (limited by boat material) | Very high (up to 3,500°C) |

| Material Compatibility | Lower melting point materials | Refractory metals, dielectrics |

| Film Purity | Potential boat contamination | High purity (water-cooled hearth) |

| Deposition Rate | Moderate | Higher |

| Process Complexity | Simple, lower cost | Complex, higher cost |

| Multi-layer Capability | Limited | Excellent with multi-pocket sources |

Struggling to choose the right evaporation method for your thin film application?

KINTEK specializes in lab equipment and consumables for all your deposition needs. Our experts can help you select the perfect system based on your material requirements, purity standards, and budget constraints.

Contact us today to discuss how our thermal and electron beam evaporation solutions can enhance your research or production process. Let us help you achieve superior thin film results with the right technology for your specific application.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

People Also Ask

- What is bio-oil used for pyrolysis? Unlocking Renewable Fuel & Chemical Potential

- What are the limitations and disadvantages of powder metallurgy? Understanding the Trade-Offs for Your Application

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of a rotavap? Master Gentle Evaporation for Sensitive Compounds

- What is preventive maintenance in a laboratory? A Proactive Strategy for Lab Reliability and Data Integrity

- What is the difference between traditional sintering and selective laser sintering? Choose the Right Manufacturing Path

- How does sintering affect porosity? Master the Thermal Process for Precise Material Density

- What are the disadvantages of plasma gasification? The Critical Gaps in Its Waste-to-Energy Promise