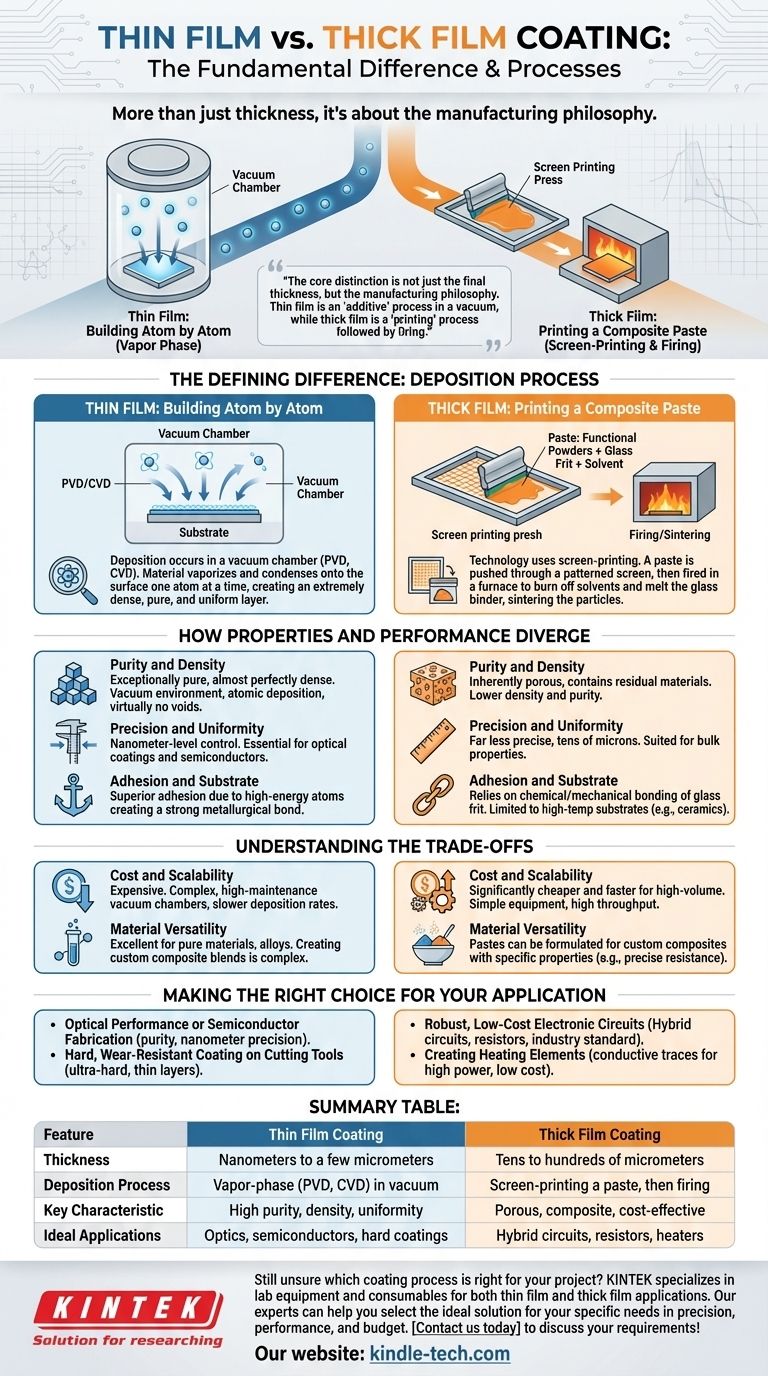

The fundamental difference between thin film and thick film coating lies in their thickness and, more importantly, the process used to create them. Thin films are typically nanometers to a few micrometers thick and are deposited atom-by-atom from a vapor phase. In contrast, thick films are tens to hundreds of micrometers thick and are applied as a screen-printable paste.

The core distinction is not just the final thickness, but the manufacturing philosophy. Thin film is an "additive" process building a solid layer from individual atoms in a vacuum, while thick film is a "printing" process applying a liquid-like paste that is then fired to form a solid.

The Defining Difference: Deposition Process

The method of application dictates nearly every characteristic of the final coating, from its purity and density to its cost and potential uses.

Thin Film: Building Atom by Atom

Thin film deposition occurs in a vacuum chamber. Processes like Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) are used.

In these methods, material is vaporized and then condenses onto the substrate surface one atom or molecule at a time. This atomic-level construction creates an extremely dense, pure, and uniform layer.

Thick Film: Printing a Composite Paste

Thick film technology uses a process similar to screen-printing. A special "ink" or paste, which is a mixture of functional powders, a glass frit binder, and an organic solvent, is pushed through a patterned screen onto a substrate.

After printing, the part is heated in a furnace. This firing process burns off the organic solvent and melts the glass binder, which sinters the functional particles together into a solid, cohesive film.

How Properties and Performance Diverge

The dramatic difference in deposition methods leads to coatings with fundamentally different characteristics.

Purity and Density

Thin films are exceptionally pure and almost perfectly dense. The vacuum environment prevents contamination, and the atomic deposition process leaves virtually no voids in the film structure.

Thick films are inherently porous and contain residual materials from the glass binder. This lower density and purity can impact electrical and mechanical performance compared to a thin film of the same base material.

Precision and Uniformity

Thin film processes offer nanometer-level control over thickness. This precision is essential for applications like optical coatings and semiconductor devices, where even tiny variations can alter performance.

Thick film thickness is far less precise and is typically measured in tens of microns. It is better suited for applications where bulk properties are more important than microscopic precision.

Adhesion and Substrate

Thin films often exhibit superior adhesion because the high-energy atoms embed themselves into the substrate surface, creating a strong metallurgical bond.

Thick film adhesion relies on the chemical and mechanical bonding of the glass frit to the substrate during the firing cycle. While this bond is very robust, it is generally limited to substrates that can withstand high firing temperatures, such as ceramics.

Understanding the Trade-offs

Choosing between these technologies is a classic engineering trade-off between performance, complexity, and cost.

Cost and Scalability

Thick film processing is significantly cheaper and faster for high-volume manufacturing. The screen-printing equipment is relatively simple, operates at atmospheric pressure, and has a very high throughput.

Thin film deposition is expensive. It requires complex, high-maintenance vacuum chambers, and the deposition rates are much slower, making it a more costly and time-consuming process.

Material Versatility

Thick film pastes can be formulated by mixing various powders to create custom composites with specific electrical or mechanical properties, such as a precise resistance value.

Thin film methods are excellent for depositing pure materials, alloys, and certain compounds. However, creating custom composite blends is significantly more complex than simply mixing a paste.

Making the Right Choice for Your Application

Your decision should be driven by the primary performance requirement of your component.

- If your primary focus is optical performance or semiconductor fabrication: Thin film is the only choice due to its required purity, uniformity, and nanometer-scale precision.

- If your primary focus is creating robust, low-cost electronic circuits (like hybrid circuits or resistors): Thick film is the industry standard for its cost-effectiveness and scalability.

- If your primary focus is a hard, wear-resistant coating on cutting tools: Thin film processes like PVD are used to create ultra-hard, thin layers (e.g., Titanium Nitride) that don't alter the tool's dimensions.

- If your primary focus is creating heating elements on a ceramic or glass substrate: Thick film is the ideal choice for printing conductive traces that can handle high power at a low cost.

Ultimately, understanding the core process—building from vapor versus printing a paste—empowers you to select the technology that aligns perfectly with your project's goals.

Summary Table:

| Feature | Thin Film Coating | Thick Film Coating |

|---|---|---|

| Thickness | Nanometers to a few micrometers | Tens to hundreds of micrometers |

| Deposition Process | Vapor-phase (PVD, CVD) in vacuum | Screen-printing a paste, then firing |

| Key Characteristic | High purity, density, uniformity | Porous, composite, cost-effective |

| Ideal Applications | Optics, semiconductors, hard coatings | Hybrid circuits, resistors, heaters |

Still unsure which coating process is right for your project? KINTEK specializes in lab equipment and consumables for both thin film and thick film applications. Our experts can help you select the ideal solution for your specific needs in precision, performance, and budget. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- Are CVD diamonds worth it? Unlock Brilliant Value & Ethical Clarity

- What is the difference between physical deposition and chemical deposition? Choose the Right Thin-Film Technology

- What is the CVD method for synthetic diamonds? Grow Lab Diamonds from Gas with Precision

- What is the apparatus of chemical vapor deposition? The Essential Components for Thin Film Deposition

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis