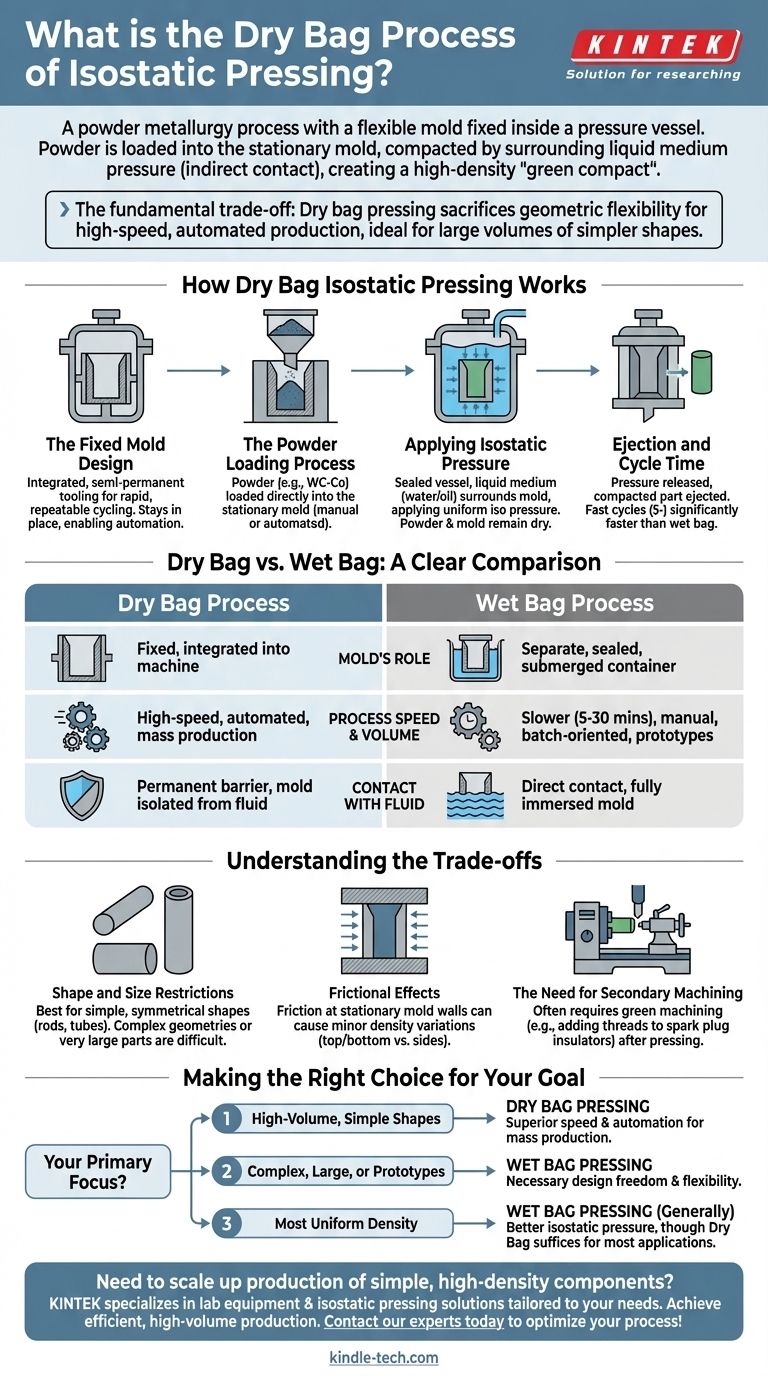

At its core, dry bag isostatic pressing is a powder metallurgy process where a flexible mold is fixed inside a pressure vessel. Powder is loaded into this stationary mold, and pressure is applied by a liquid medium that surrounds the mold but never directly touches it. This compacts the powder into a solid, high-density component known as a "green compact."

The fundamental trade-off in isostatic pressing is speed versus complexity. Dry bag pressing sacrifices geometric flexibility for high-speed, automated production, making it ideal for manufacturing large volumes of simpler shapes.

How Dry Bag Isostatic Pressing Works

The dry bag process is defined by its integrated, semi-permanent tooling, which enables rapid and repeatable cycling. This design is what sets it apart from other isostatic methods.

The Fixed Mold Design

Unlike other processes, the flexible mold in dry bag pressing is a built-in part of the pressure vessel. It remains in place during operation and is not removed between cycles.

This integrated design is the key to the process's speed and suitability for automation.

The Powder Loading Process

Powder, such as tungsten carbide-cobalt (WC-Co), is loaded directly into the fixed mold. This can be done manually for smaller runs or, more commonly, through an automated feeding hopper from above for mass production.

Applying Isostatic Pressure

Once the mold is filled, the pressure vessel is sealed. A liquid medium (typically water or oil) is pumped into the vessel, surrounding the external surface of the flexible mold.

This fluid applies uniform, or "isostatic," pressure, compressing the powder inside the mold into a solid mass with a dense, compact microstructure. The powder and mold are kept "dry" and isolated from the fluid.

Ejection and Cycle Time

After a brief hold, the pressure is released, and the compacted part—the "green compact"—is ejected from the mold. The entire system is then immediately ready for the next cycle.

A single press run can last as little as 5 to 10 minutes, making it significantly faster than the alternative wet bag process.

Dry Bag vs. Wet Bag: A Clear Comparison

Understanding the dry bag process requires contrasting it with its counterpart, wet bag pressing. The choice between them depends entirely on the manufacturing goal.

The Mold's Role

In dry bag pressing, the mold is fixed and part of the machine. In wet bag pressing, the mold is a separate, sealed container that is filled with powder and then fully submerged into the pressure vessel's fluid.

Process Speed and Volume

Dry bag is engineered for speed and automation, making it the standard for high-volume mass production.

Wet bag is a more manual, batch-oriented process. With cycle times from 5 to 30 minutes, it is better suited for prototypes, one-off parts, or low-volume production runs.

Contact with the Fluid

This is the defining difference. In the dry bag method, there is a permanent barrier between the pressure fluid and the mold. In the wet bag method, the sealed mold is in direct contact with and fully immersed in the pressure fluid.

Understanding the Trade-offs of Dry Bag Pressing

While highly efficient, the dry bag method has inherent limitations that make it unsuitable for certain applications. Objectively assessing these trade-offs is critical.

Limitation 1: Shape and Size Restrictions

Because the tooling is fixed and integrated, the dry bag process is best for producing relatively simple and symmetrical shapes, such as rods, tubes, and spark plug insulators.

Complex geometries, undercuts, or very large components are difficult or impossible to produce and are better handled by the more flexible wet bag method.

Limitation 2: Frictional Effects

In a perfect isostatic system, pressure is equal from all directions. However, in the dry bag process, friction can occur where the powder meets the stationary mold walls.

This can result in minor density variations within the component, as the top and bottom of the part may not experience the exact same compaction forces as the sides.

The Need for Secondary Machining

Due to the shape limitations, parts made via dry bag pressing often require secondary processing. For example, spark plug insulators are pressed into a basic shape and then require green machining (machining the part before final sintering) to add threads and other surface features.

Making the Right Choice for Your Goal

Selecting the correct isostatic process requires aligning the method's capabilities with your specific production objectives.

- If your primary focus is high-volume production of simple shapes: Dry bag pressing is the clear choice due to its superior speed and suitability for automation.

- If your primary focus is producing complex, large, or prototype parts: Wet bag pressing provides the necessary design freedom and flexibility, justifying its slower cycle time.

- If your primary focus is achieving the most uniform density possible for a critical part: Wet bag pressing generally offers more truly isostatic pressure, though dry bag is sufficient for the vast majority of industrial applications.

Ultimately, the right choice is determined by balancing the demands of your part's geometry against your required production volume and speed.

Summary Table:

| Feature | Dry Bag Process | Wet Bag Process |

|---|---|---|

| Mold Type | Fixed, integrated into the machine | Separate, removable container |

| Cycle Time | Fast (5-10 minutes) | Slower (5-30 minutes) |

| Production Volume | High-volume, mass production | Low-volume, prototypes, one-offs |

| Part Complexity | Simple, symmetrical shapes (rods, tubes) | Complex geometries, large parts |

| Automation | Highly suitable for automation | Manual, batch-oriented |

| Fluid Contact | Mold is isolated from the pressure fluid | Mold is fully immersed in the pressure fluid |

Need to scale up production of simple, high-density components? KINTEK specializes in lab equipment and consumables, including isostatic pressing solutions tailored to your laboratory's needs. Our expertise can help you achieve efficient, high-volume production with the right pressing technology. Contact our experts today to discuss how our solutions can optimize your process!

Visual Guide

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What advantages does CIP equipment offer for W-TiC composites? Achieve High-Density, Defect-Free Materials

- In what ways does Cold Isostatic Pressing (CIP) enhance LiFePO4 battery performance? Boost Density and Conductivity

- What advantages does a Cold Isostatic Press (CIP) offer for solid-state batteries? Superior Density & Uniformity

- Why is a cold isostatic press (CIP) required after Li/Li3PS4-LiI/Li battery assembly? Optimize Your Solid-State Interface

- What is the role of a Cold Isostatic Press (CIP) in C-PSC lamination? Enhance Solar Efficiency Without Heat