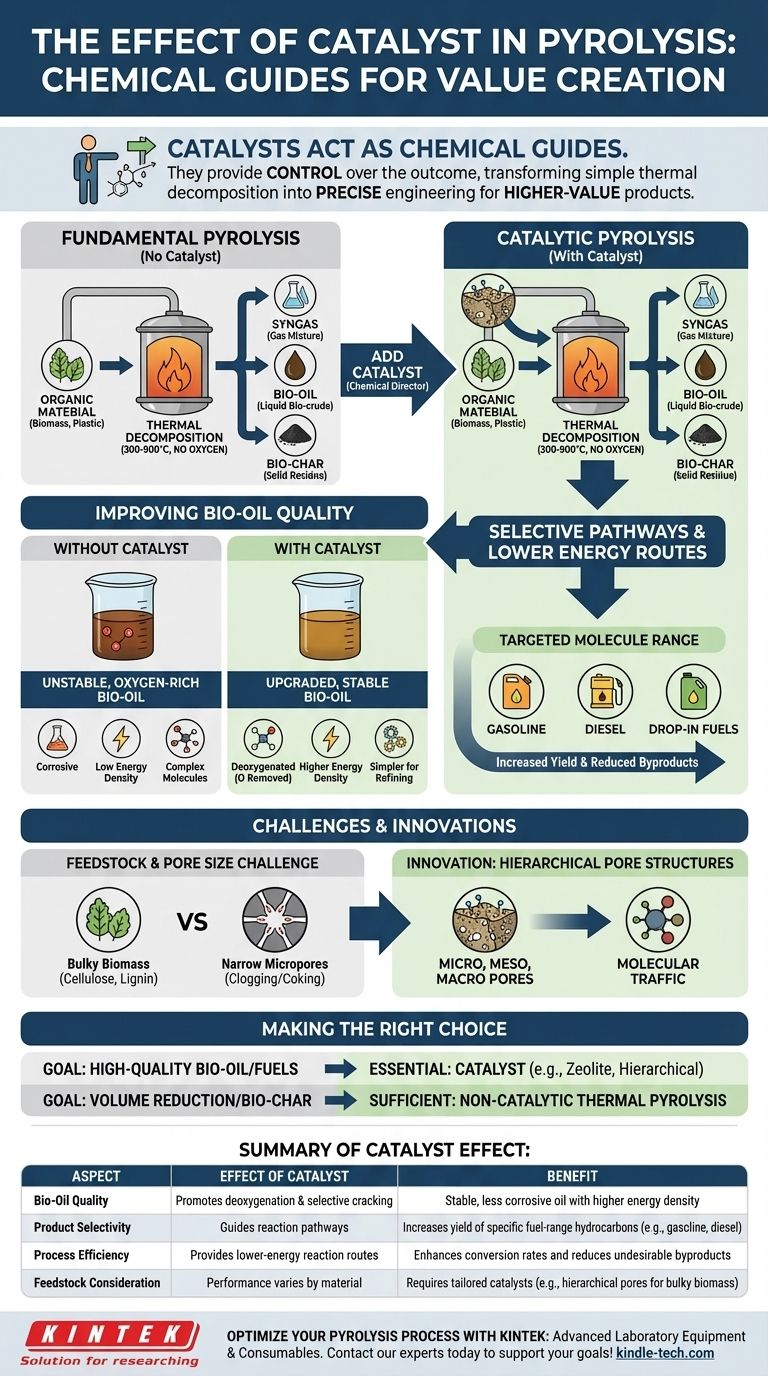

In short, catalysts act as chemical guides in the pyrolysis process. They are substances added to promote specific reactions, selectively breaking down organic materials into more valuable, higher-quality products. While pyrolysis can occur without a catalyst, adding one enhances the process's efficiency and, most importantly, improves the quality of the resulting fuel or chemical precursors.

The core function of a catalyst in pyrolysis is to provide control over the chemical outcome. It transforms the process from simple thermal decomposition into a more precise method for engineering a higher-value liquid product (bio-oil) that is easier to upgrade into drop-in fuels.

The Fundamental Role of a Catalyst

To understand a catalyst's effect, we must first understand the basic pyrolysis process it modifies.

Defining Pyrolysis: Thermal Decomposition

Pyrolysis is a process where organic material, such as biomass or plastic, is heated to high temperatures (typically 300-900°C) in an environment without oxygen.

This absence of oxygen is critical. It ensures the material does not combust but instead breaks down (decomposes) into a mixture of gases (syngas), liquids (bio-oil), and a solid residue (bio-char).

Introducing the Catalyst: A Chemical Director

A catalyst directs the chemical pathways during this decomposition. It provides an alternative, lower-energy route for specific reactions to occur, steering the breakdown of large organic polymers toward desired smaller molecules.

The catalyst itself is not consumed in the reaction but provides a surface where these transformations can happen more efficiently.

The Goal: Improving Product Quality

The primary effect of using a catalyst is the production of a higher-quality bio-oil.

This upgraded oil contains molecules more similar to those found in conventional hydrocarbon fuels. This makes the subsequent refining process simpler and more cost-effective.

How Catalysts Upgrade Pyrolysis Products

Catalysts achieve this upgrade by influencing the chemical composition of the final products in several key ways.

Enhancing Bio-Oil Value

Catalytic pyrolysis is specifically designed to maximize the yield and quality of the liquid bio-oil. The reactions promoted by the catalyst often involve removing oxygen from the biomass molecules, a crucial step known as deoxygenation.

The resulting bio-oil is more stable, has a higher energy density, and is less corrosive than oil produced without a catalyst.

Increasing Selectivity for Fuels

By guiding the reaction pathways, catalysts can selectively produce molecules within a specific size range, such as those found in gasoline or diesel. This selectivity reduces the amount of undesirable byproducts and increases the yield of valuable "drop-in" fuel components.

Understanding the Trade-offs and Limitations

While highly beneficial, catalytic pyrolysis is not a universal solution. The effectiveness of a catalyst is highly dependent on the feedstock and process conditions.

The Challenge of Feedstock Type

Commercial catalysts, such as zeolite-based or silicon-based types, perform well in petrochemical applications but face significant challenges with biomass.

The natural polymers in biomass (like cellulose and lignin) are much bulkier than the molecules found in plastics.

The Problem of Catalyst Pore Size

The issue lies in the physical structure of the catalyst. Many commercial catalysts have very narrow micropores. While effective for small molecules, these pores can be too small for the large polymers in biomass to enter.

This can lead to the catalyst becoming clogged or "coked" on its exterior surface, quickly deactivating it and halting its beneficial effects.

The Influence of Process Conditions

Catalyst performance is also tied to overall process efficiency. Factors like feedstock moisture content (ideally around 10%) and particle size (often under 2 mm) are critical for ensuring rapid heat transfer and optimal interaction with the catalyst.

Innovations in Catalyst Design

To overcome these limitations, research is focused on creating catalysts with a multi-dimensional or hierarchical pore structure. By engineering micro, meso, and macro pores, these advanced catalysts can better manage the "molecular traffic" of large biomass components, improving access and efficiency.

Making the Right Choice for Your Goal

The decision to use a catalyst—and which type—depends entirely on your feedstock and desired end product.

- If your primary focus is producing high-quality, upgradable bio-oil: A catalyst is essential for steering reactions toward valuable fuel precursors and improving oil stability.

- If you are processing plastic waste: Commercially available zeolite catalysts can be highly effective for selectively producing specific hydrocarbon fuel ranges.

- If your feedstock is bulky biomass: You must consider advanced catalysts with hierarchical pore structures to avoid deactivation and accommodate larger molecules.

- If your goal is simply volume reduction or producing bio-char: A non-catalytic thermal pyrolysis process may be sufficient and more cost-effective.

Ultimately, a catalyst transforms pyrolysis from a brute-force decomposition process into a precise chemical manufacturing tool.

Summary Table:

| Aspect | Effect of Catalyst | Benefit |

|---|---|---|

| Bio-Oil Quality | Promotes deoxygenation and selective cracking | Produces stable, less corrosive oil with higher energy density |

| Product Selectivity | Guides reaction pathways | Increases yield of specific fuel-range hydrocarbons (e.g., gasoline, diesel) |

| Process Efficiency | Provides lower-energy reaction routes | Enhances conversion rates and reduces undesirable byproducts |

| Feedstock Consideration | Performance varies by material (e.g., plastics vs. biomass) | Requires tailored catalysts (e.g., hierarchical pores for bulky biomass) |

Ready to optimize your pyrolysis process with the right catalyst? KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Whether you're working with biomass, plastics, or other feedstocks, our expertise can help you select the right tools to achieve higher-quality bio-oil and maximize fuel yields. Contact our experts today to discuss how we can support your catalytic pyrolysis goals!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals