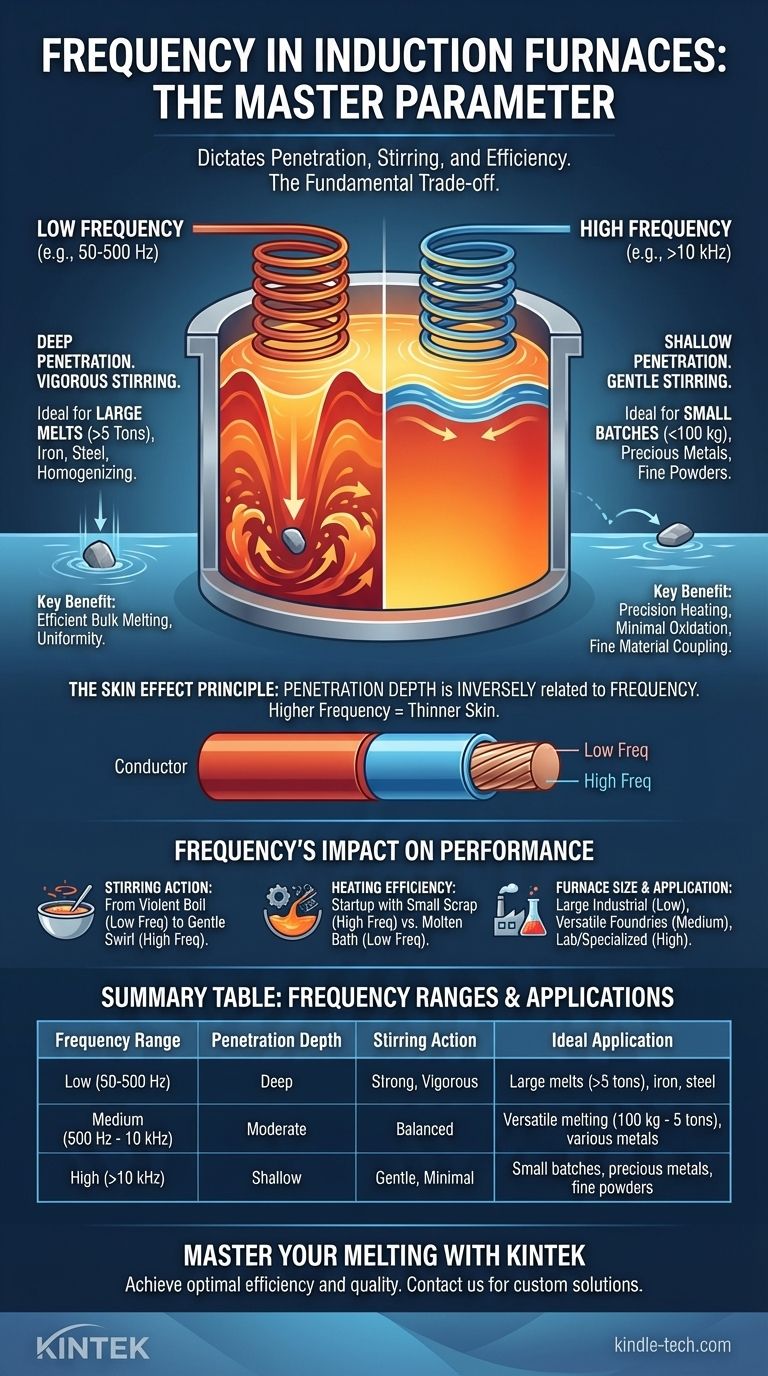

The operating frequency of an induction furnace is not just a technical detail; it is the primary parameter that governs its behavior. In simple terms, frequency determines how deeply the heating energy penetrates the metal charge. This, in turn, dictates the intensity of the stirring action, the efficiency of the melting process, and the ideal furnace size for a specific application. Lower frequencies penetrate deeper and stir more vigorously, while higher frequencies heat the surface and stir gently.

Choosing the right frequency involves a fundamental trade-off. Lower frequencies provide deep penetration and strong stirring ideal for large melts, while higher frequencies offer precise surface heating with minimal stirring, which is better suited for small batches or fine materials. Understanding this trade-off is the key to mastering induction melting.

The Core Principle: Skin Effect and Penetration Depth

To understand the role of frequency, you must first understand the physics of induction heating itself. The process relies on a phenomenon known as the "skin effect."

What is the Skin Effect?

When an alternating current (AC) is induced in a conductor—in this case, the metal inside the furnace—it does not flow uniformly through the entire cross-section. Instead, the current tends to concentrate in a thin layer on the material's surface.

This surface layer is called the skin depth or penetration depth. The vast majority of the heating occurs within this active region.

How Frequency Controls Penetration

The thickness of this skin depth is inversely related to the frequency of the power supply. The relationship is simple and direct:

- Low Frequency (e.g., 50/60 Hz): Results in a large penetration depth. The current and heating energy reach deep into the metal charge.

- High Frequency (e.g., 10,000 Hz or 10 kHz): Results in a very small penetration depth. The current and heating are concentrated in a thin layer right at the surface.

Think of it like skipping a stone on water. A fast, high-frequency spin causes the stone to skip along the surface. A slow, low-frequency toss causes it to plunge deep into the water.

Frequency's Impact on Furnace Performance

This relationship between frequency and penetration depth has direct, practical consequences for every aspect of the furnace's operation.

Stirring Action: From Violent Boil to Gentle Swirl

The interaction between the magnetic field and the induced current creates Lorentz forces, which cause the molten metal to move and stir. The intensity of this stirring is directly linked to frequency.

- Low-frequency furnaces produce a powerful, deep stirring action. This is highly effective for homogenizing large melts, mixing in alloys, and ensuring uniform temperature.

- High-frequency furnaces produce a much gentler, surface-level stirring. This is desirable for small melts or when melting metals that are prone to oxidation, as it minimizes exposure of the molten metal to the atmosphere.

Heating Efficiency and Coupling

For efficient heating, the magnetic field must "couple" effectively with the metal charge. The size of the metal pieces relative to the penetration depth is critical.

A general rule of thumb is that for efficient power transfer, the diameter of the metal pieces should be at least three to four times the penetration depth.

- At startup with small scrap: High frequency is more efficient. Its small penetration depth couples well with small pieces, shavings, or turnings. A low frequency's large magnetic field would pass right through the gaps with little effect.

- With a molten bath: Low frequency becomes highly efficient. Its deep penetration couples perfectly with the large, single mass of liquid metal, and the strong stirring action rapidly distributes the heat.

Furnace Size and Application

These principles naturally lead to different frequencies being used for different scales of operation.

- Low Frequency (Line Frequency - 50/60 Hz to ~500 Hz): Used for large industrial furnaces (several tons to over 100 tons) for bulk melting of iron, steel, and holding applications. The strong stirring is a key feature.

- Medium Frequency (~500 Hz to 10 kHz): The most versatile range, used in foundries for furnaces from a few hundred kilograms to several tons. It offers a good balance of stirring and starting efficiency for various metals like steel, copper alloys, and aluminum.

- High Frequency (>10 kHz): Reserved for small laboratory furnaces, melting precious metals, or specialized applications like heat treating and brazing. The minimal stirring and ability to couple with very fine materials are the main advantages.

Understanding the Trade-offs and Pitfalls

Selecting the wrong frequency for your application leads to inefficiency, poor metallurgical results, and operational problems.

The Problem of a "Dead" Start

Attempting to melt a charge of small, loose scrap in a very low-frequency furnace is highly inefficient. The power coupling will be poor, leading to extremely long melt times or a complete failure to start the melt from cold.

The Risk of Excessive Stirring

Using a frequency that is too low for your specific melt can create an overly violent "boil." This excessive turbulence can increase refractory wear on the furnace lining, cause unwanted gas pickup from the atmosphere, and lead to higher metal losses through oxidation.

Power Supply Complexity and Cost

While line-frequency (50/60 Hz) systems are simple, they offer no flexibility. To generate medium and high frequencies, furnaces require solid-state power supplies (inverters). These systems provide precise control but add significant cost and complexity to the overall installation.

Making the Right Choice for Your Goal

The choice of frequency is a strategic decision based on your material, batch size, and desired metallurgical outcome.

- If your primary focus is melting large volumes (>5 tons) of iron or steel: A low-frequency (line or sub-500 Hz) furnace provides the deep penetration and strong stirring needed for efficient bulk melting.

- If your primary focus is versatile melting (100 kg to 5 tons) of various metals: A medium-frequency furnace (500 Hz to 3 kHz) offers the best all-around balance of starting power, stirring, and efficiency.

- If your primary focus is melting small batches (<100 kg), precious metals, or fine powders: A high-frequency furnace (>10 kHz) provides the precise, gentle heating required and couples effectively with small-sized materials.

Ultimately, selecting the correct frequency aligns the physics of induction with your specific metallurgical and production goals.

Summary Table:

| Frequency Range | Penetration Depth | Stirring Action | Ideal Application |

|---|---|---|---|

| Low (50-500 Hz) | Deep | Strong, Vigorous | Large melts (>5 tons), iron, steel |

| Medium (500 Hz - 10 kHz) | Moderate | Balanced | Versatile melting (100 kg - 5 tons), various metals |

| High (>10 kHz) | Shallow | Gentle, Minimal | Small batches, precious metals, fine powders |

Master Your Melting Process with KINTEK

Choosing the right frequency for your induction furnace is critical for achieving optimal efficiency, metal quality, and operational cost savings. Whether you're processing large volumes of steel or delicate precious metals, the wrong frequency can lead to poor coupling, excessive stirring, or failed starts.

At KINTEK, we specialize in providing precision lab equipment and consumables tailored to your specific melting needs. Our experts can help you select the ideal furnace configuration to ensure deep penetration, controlled stirring, and maximum energy efficiency for your application.

Contact us today to discuss your requirements and let KINTEK's solutions enhance your laboratory's melting capabilities.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What are the typical heating zone configurations and maximum temperature capabilities of tube furnaces? Find the Right Setup for Your Lab

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?