In short, increasing mill speed results in a finer final product. This occurs because a faster rotation generates more frequent and forceful collisions between the grinding media, leading to more effective particle size reduction.

The core principle to understand is that mill speed is not just about velocity; it's about controlling the type of grinding action. By changing the speed, you are fundamentally altering the balance between high-energy impacts and lower-energy abrasive forces inside the mill.

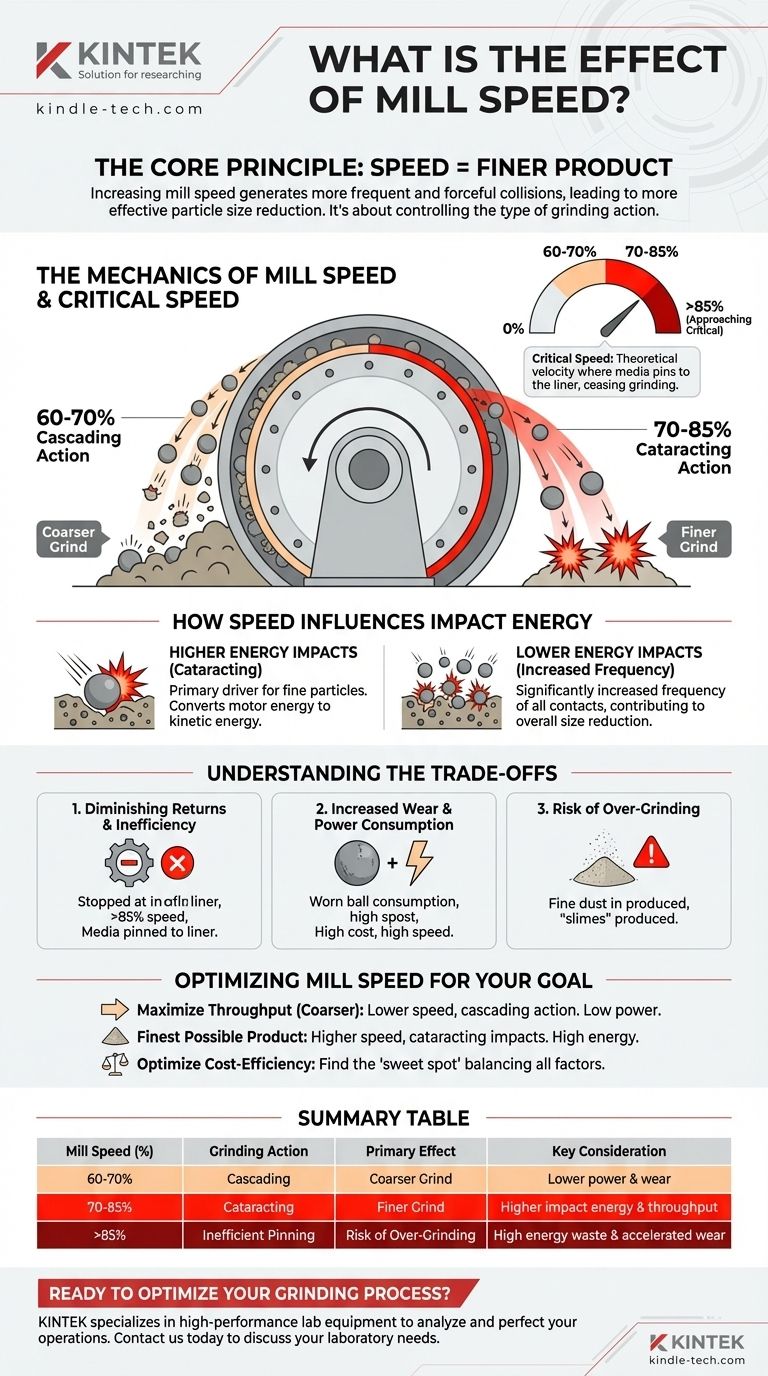

The Mechanics of Mill Speed

To effectively control your grinding process, you must understand how rotational speed changes the physics within the mill shell. This is governed by a key concept known as "critical speed."

The Concept of Critical Speed

Critical speed is the theoretical velocity at which centrifugal force would cause the grinding media (like steel balls or rods) to pin against the mill liner, effectively ceasing all grinding action.

Operational mill speed is therefore always discussed as a percentage of critical speed. This percentage determines the character of the grinding.

From Cascading to Cataracting

At lower speeds (e.g., 60-70% of critical), the grinding media "cascades." This means the media tumbles down the face of the charge, creating a rubbing and abrasive action that is effective for coarser grinding.

As you increase the speed (e.g., 70-85% of critical), the action shifts to "cataracting." The media is thrown further up the liner and into the air, creating a free-fall that results in high-energy impacts on the ore below.

How Speed Influences Impact Energy

The statement that increased speed generates both "higher and lower energy impacts" is key.

The higher energy impacts are a direct result of the cataracting motion. A faster mill throws the media higher, converting more motor energy into potential energy, which then becomes kinetic energy upon impact. This is the primary driver for creating fine particles.

The lower energy impacts refer to the significantly increased frequency of all collisions. With everything moving faster, the number of smaller, incidental contacts and abrasive interactions also rises dramatically, contributing to overall size reduction.

Understanding the Trade-offs

Simply running a mill at its maximum possible speed is rarely the most effective or economical strategy. The benefits of a finer grind come with significant operational costs and physical limitations.

Diminishing Returns and Inefficiency

There is an optimal speed for efficiency. As you approach critical speed, the media spends more time pinned to the liner, reducing the number of effective impacts. Pushing past the optimal point wastes energy without a proportional increase in grinding performance.

Increased Wear and Power Consumption

Higher speeds and more energetic impacts directly translate to accelerated wear on both the grinding media and the mill liners. This increases maintenance frequency and replacement costs. Furthermore, running at higher speeds requires significantly more power, which is often the largest single operating cost for a grinding circuit.

Risk of Over-Grinding

For many applications, especially in mineral processing, producing excessive ultra-fine particles (or "slimes") can be detrimental to downstream recovery processes like flotation. A higher mill speed increases the risk of over-grinding valuable material into a particle size that is too fine to be recovered efficiently.

Optimizing Mill Speed for Your Goal

The correct mill speed is entirely dependent on the objective of your specific operation. You must balance product size requirements with operational costs.

- If your primary focus is maximizing throughput with a coarser product: Operate at a lower percentage of critical speed to promote a cascading, abrasive action that consumes less power and causes less wear.

- If your primary focus is producing the finest possible product: Operate at a higher percentage of critical speed to maximize the number of high-energy, cataracting impacts.

- If your primary focus is optimizing cost-efficiency: You must find the operational "sweet spot" that balances throughput and particle size against the costs of power consumption and media/liner wear.

Ultimately, controlling mill speed is about deliberately managing the internal physics of the mill to achieve your precise operational target.

Summary Table:

| Mill Speed (as % of Critical Speed) | Grinding Action | Primary Effect on Product | Key Consideration |

|---|---|---|---|

| 60-70% | Cascading | Coarser Grind | Lower power consumption and wear |

| 70-85% | Cataracting | Finer Grind | Higher impact energy and throughput |

| >85% (Approaching Critical) | Inefficient Pinning | Risk of Over-Grinding | High energy waste and accelerated wear |

Ready to Optimize Your Grinding Process?

Finding the perfect mill speed for your specific material and production goals is key to maximizing efficiency and profitability. The experts at KINTEK specialize in providing high-performance lab equipment and consumables to help you analyze and perfect your grinding operations.

We understand the critical balance between particle size, throughput, and operational costs. Let us equip your laboratory with the right tools to achieve superior results.

Contact KINTEL today to discuss your laboratory needs and discover how our solutions can enhance your process control and product quality.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding