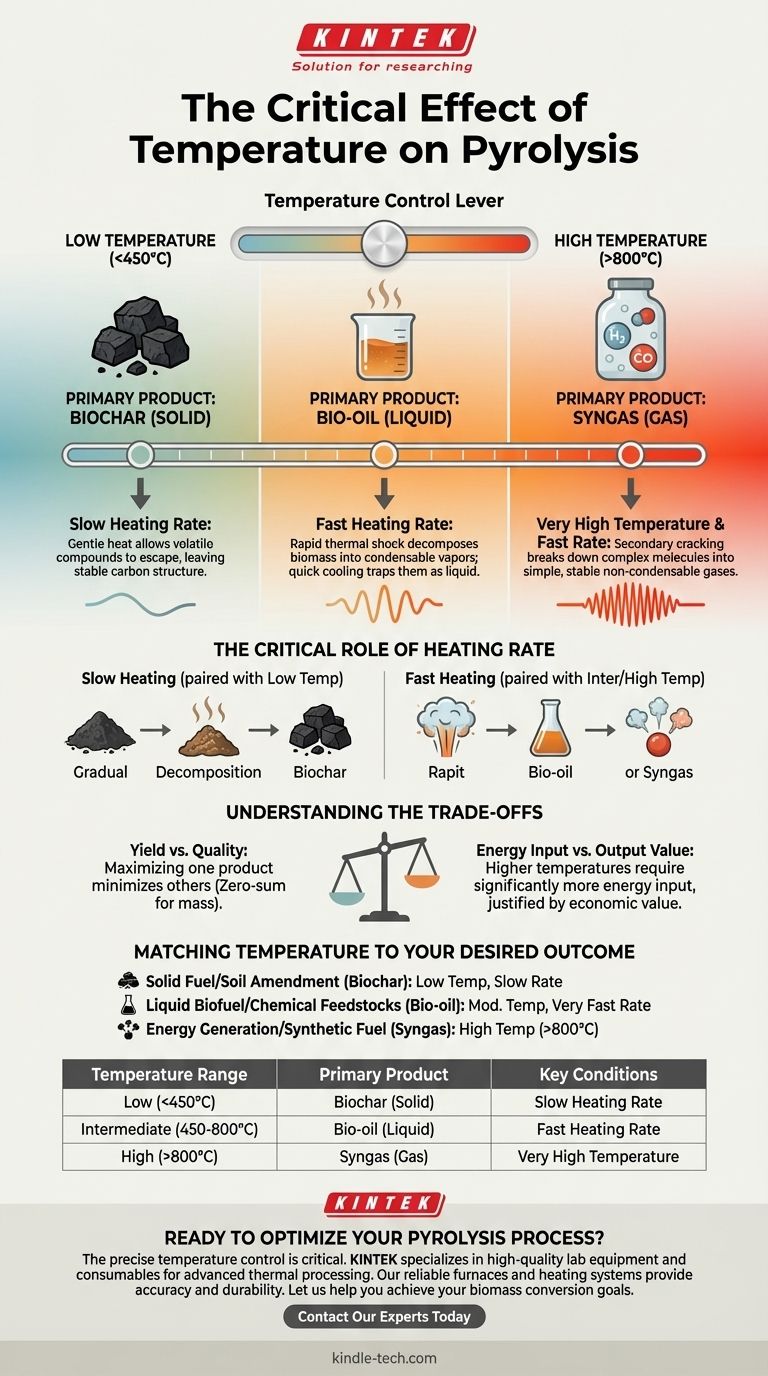

In short, temperature is the single most critical factor in determining the outcome of pyrolysis. Lower temperatures favor the creation of solid biochar, while higher temperatures increasingly favor the production of liquid bio-oil and, eventually, non-condensable gases like syngas. The rate at which the temperature is applied is also a crucial, interconnected variable.

The core principle is this: Temperature acts as a control lever, dictating whether biomass deconstructs primarily into a solid carbon structure (biochar), condensable liquid vapors (bio-oil), or simple, non-condensable gas molecules (syngas).

How Temperature Dictates Pyrolysis Products

Pyrolysis is the thermal decomposition of material in the absence of oxygen. By precisely controlling the thermal environment, you can steer the process to maximize the yield of one specific product type over the others.

Low Temperature (<450°C): Maximizing Biochar

At lower temperatures, typically below 450°C, and with slow heating rates, the process is optimized for biochar production.

The gentle heat allows volatile compounds to be driven off gradually, leaving behind a stable, carbon-rich solid structure. This slow "roasting" process minimizes the further breakdown of the carbon skeleton.

Intermediate Temperature (450-800°C): Optimizing for Bio-oil

This is the primary range for producing bio-oil. It requires moderate to high temperatures and, critically, fast heating rates.

The rapid thermal shock causes the biomass to rapidly decompose into a mix of condensable vapors. These vapors are then quickly cooled and condensed into a liquid, preventing them from breaking down further into gases.

High Temperature (>800°C): Driving Gas Production

To maximize the yield of syngas (a mixture of hydrogen and carbon monoxide), very high temperatures are required.

At these extremes, any liquids or solids that form are subjected to secondary cracking. This process breaks down complex hydrocarbon molecules into the simplest, most stable non-condensable gas molecules.

The Critical Role of Heating Rate

Temperature does not work in isolation. The heating rate, or how quickly the target temperature is reached, is a co-dependent variable that profoundly influences the final product distribution.

Slow Heating vs. Fast Heating

A slow heating rate gives volatile compounds time to escape before the core carbon structure breaks down, which is why it is paired with low temperatures to produce biochar.

A fast heating rate creates a rapid decomposition, generating a surge of vapors ideal for bio-oil production. When combined with very high temperatures, this rapid rate ensures all components are quickly broken down into gas.

Understanding the Trade-offs

Choosing a target temperature is an exercise in balancing competing priorities. There is no single "best" temperature; there is only the best temperature for a specific goal.

Yield vs. Quality

Maximizing the yield of one product (e.g., gas) inherently means minimizing the yield of others (biochar and bio-oil). The process is a zero-sum game for the feedstock's mass.

Energy Input vs. Output Value

Achieving higher temperatures requires a significantly greater energy input. This operational cost must be justified by the economic value of the desired product. Producing high-value syngas for chemical synthesis may warrant the high energy cost, while producing biochar for soil amendment would not.

Matching Temperature to Your Desired Outcome

Your operational parameters should be dictated entirely by your end goal for the pyrolyzed material.

- If your primary focus is solid fuel or soil amendment (Biochar): Operate at low temperatures (<450°C) with slow heating rates to maximize the solid yield.

- If your primary focus is liquid biofuel or chemical feedstocks (Bio-oil): Use moderate temperatures (450-800°C) combined with very fast heating rates to capture condensable vapors.

- If your primary focus is energy generation or synthetic fuel (Syngas): Employ high temperatures (>800°C) to ensure the complete thermal cracking of all components into gas.

Ultimately, mastering pyrolysis is about using temperature to precisely control the deconstruction of biomass into the valuable product you need.

Summary Table:

| Temperature Range | Primary Product | Key Conditions |

|---|---|---|

| Low (<450°C) | Biochar (Solid) | Slow Heating Rate |

| Intermediate (450-800°C) | Bio-oil (Liquid) | Fast Heating Rate |

| High (>800°C) | Syngas (Gas) | Very High Temperature |

Ready to optimize your pyrolysis process for maximum yield and efficiency?

The precise temperature control discussed in this article is critical for success. At KINTEK, we specialize in high-quality lab equipment and consumables designed for advanced thermal processing. Whether you are researching biochar, bio-oil, or syngas production, our reliable furnaces and heating systems provide the accuracy and durability you need.

Let us help you achieve your biomass conversion goals. Contact our experts today to discuss your specific laboratory requirements and discover how KINTEK can be your partner in innovation.

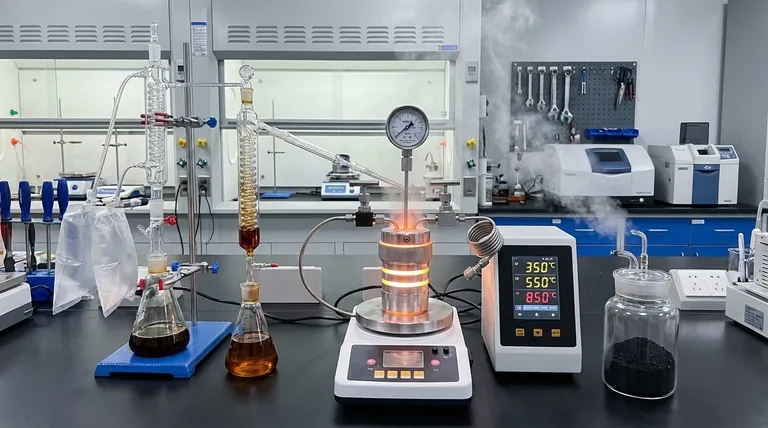

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Wall Mounted Water Distillation Unit

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

People Also Ask

- Why use high-pressure reactors for food waste pretreatment? Boost Hydrogen Production Efficiency Today!

- What role does a high-pressure reactor play in the hydrodeoxygenation (HDO) of bio-oil? Drive Deep Fuel Upgrading

- What are the technical characteristics of PTFE (Teflon) lined hydrothermal reactors? Comparing α-ZrP Synthesis Methods

- What role does a PTFE-lined stainless steel autoclave play in the synthesis of BiOBr precursor nanosheets?

- Why is a high-pressure hydrothermal synthesis autoclave necessary for MnO2 nanowires? Precision Catalyst Growth