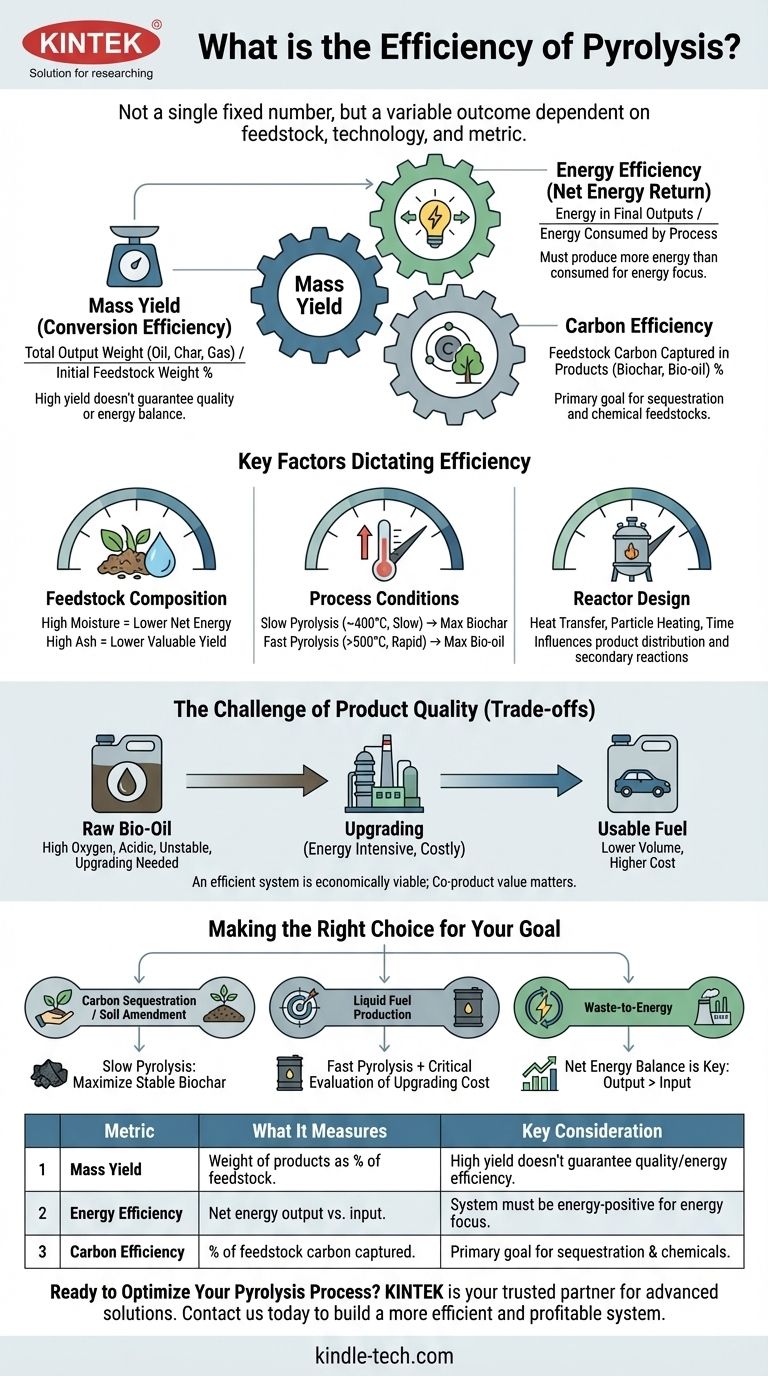

The efficiency of pyrolysis is not a single, fixed number. Instead, it is a variable outcome that depends entirely on the feedstock used, the technology employed, and, most importantly, which metric of "efficiency" is being measured. While a simple mass balance might show 60-90% of the initial feedstock is converted into products, the true efficiency must also account for the energy balance of the process and the quality of those products.

The central challenge in evaluating pyrolysis is understanding that high product yield does not automatically equal high efficiency. A truly efficient system is defined by its ability to produce high-quality, usable products (oil, char, gas) while maintaining a positive net energy balance.

Deconstructing Pyrolysis Efficiency: Three Key Metrics

To properly assess the process, we must look beyond a single percentage and evaluate three different types of efficiency.

Mass Yield (Conversion Efficiency)

This is the most straightforward metric. It measures the total weight of the outputs (bio-oil, biochar, and syngas) as a percentage of the initial dry weight of the feedstock.

Well-designed systems typically convert the majority of the feedstock mass into these three products, with minimal losses. However, this number alone can be misleading as it says nothing about the value or utility of those products.

Energy Efficiency (Net Energy Return)

This is the most critical measure for any energy-focused application. It compares the energy required to run the entire process—including drying feedstock, heating the reactor, and upgrading products—to the total energy content of the final outputs.

A process is only truly energy-efficient if it produces significantly more energy than it consumes. Many pyrolysis systems use the syngas they produce to power the reactor, aiming for a self-sustaining or energy-positive operation.

Carbon Efficiency

This metric tracks how much of the carbon from the original feedstock is captured in the desired products, particularly the stable biochar or the liquid bio-oil.

For applications like carbon sequestration or creating chemical feedstocks, high carbon efficiency is the primary goal. It signifies that carbon is being locked into a useful form rather than being lost to the atmosphere as CO2.

Key Factors That Dictate Efficiency

The performance of any pyrolysis system is dictated by a few fundamental variables that can be adjusted to target specific outcomes.

Feedstock Composition

The nature of the material being processed has the largest impact on efficiency. High-moisture feedstocks (like food waste) require enormous amounts of energy for drying, drastically lowering the net energy efficiency.

Likewise, materials with high ash content will result in a lower yield of valuable oil and gas.

Process Conditions (Temperature & Heating Rate)

The operational parameters of the reactor determine the distribution of products. This is the primary trade-off in pyrolysis design.

- Slow Pyrolysis: Lower temperatures (~400°C) and slow heating rates maximize the production of biochar.

- Fast Pyrolysis: Higher temperatures (>500°C) and extremely rapid heating rates maximize the production of bio-oil.

Reactor Design

The physical design of the reactor, whether a fluidized bed, auger, or rotating kiln, influences the efficiency of heat transfer into the feedstock.

A well-designed reactor ensures that every particle is heated to the target temperature for the precise amount of time needed, maximizing the yield of the desired product and preventing unwanted secondary reactions.

Understanding the Trade-offs: The Challenge of Product Quality

Achieving a high yield of a specific product is meaningless if that product is difficult or impossible to use. This is especially true for bio-oil.

The Problem with Raw Bio-Oil

The raw liquid produced from fast pyrolysis, often called bio-oil or pyrolysis oil, is not a simple replacement for petroleum crude.

As noted, it has a high oxygen content, which makes it acidic, corrosive, and thermally unstable. It is also immiscible with conventional fuels and tends to thicken or even solidify over time through polymerization.

The Hidden Cost of Upgrading

To be used as a transport fuel or in a refinery, raw bio-oil must undergo significant and energy-intensive processing called upgrading.

This process removes oxygen and reconfigures molecules, but it consumes hydrogen, requires expensive catalysts, and reduces the final volume of usable fuel. This secondary step significantly lowers the overall system efficiency.

Co-Product Value

An "efficient" system is ultimately an economically viable one. A process that produces a lower yield of a high-value product, like specialized biochar for agriculture or filtration, may be far more successful than one that produces a high yield of low-quality bio-oil that requires expensive upgrading.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on your end objective.

- If your primary focus is carbon sequestration or soil amendment: Slow pyrolysis is the superior choice, as it is engineered to maximize the yield of stable, high-carbon biochar.

- If your primary focus is liquid fuel production: You must use a fast pyrolysis system and critically evaluate the total energy and financial cost of the mandatory bio-oil upgrading stage.

- If your primary focus is waste-to-energy: The overall net energy balance is the only metric that matters; ensure the energy from all products consistently exceeds the energy required to dry the feedstock and run the plant.

Ultimately, the most "efficient" pyrolysis process is the one that aligns its outputs with your specific economic and environmental objectives.

Summary Table:

| Metric | What It Measures | Key Consideration |

|---|---|---|

| Mass Yield | Weight of products (oil, char, gas) as a % of feedstock. | High yield doesn't guarantee product quality or energy efficiency. |

| Energy Efficiency | Net energy output vs. energy input to run the process. | Critical for energy-focused applications; the system must be energy-positive. |

| Carbon Efficiency | % of feedstock carbon captured in stable products like biochar. | The primary goal for carbon sequestration and creating chemical feedstocks. |

Ready to Optimize Your Pyrolysis Process?

Choosing the right pyrolysis strategy is critical to achieving your specific goals, whether it's maximizing biochar for carbon sequestration, producing liquid fuel, or creating a waste-to-energy solution. The efficiency of your system depends on precise control over feedstock, temperature, and reactor design.

KINTEK is your trusted partner for advanced pyrolysis solutions. We specialize in supplying high-quality lab equipment and consumables for research and development, helping you accurately test and scale your pyrolysis processes. Our expertise ensures you can evaluate mass yield, energy balance, and product quality with confidence.

Let us help you build a more efficient and profitable system. Contact our experts today to discuss your project needs and discover how KINTEK's solutions can drive your success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Non Consumable Vacuum Arc Induction Melting Furnace

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions