In short, the feedstock for bio-oil is virtually any type of biomass, but the most common and effective sources are lignocellulosic materials. This broad category includes wood waste, agricultural residues like corn stover and wheat straw, and dedicated energy crops such as switchgrass. The key is that the raw material is rich in cellulose, hemicellulose, and lignin, which are the organic polymers that break down during pyrolysis to form bio-oil.

The critical insight is not simply what can be used to make bio-oil, but what should be used. The ideal feedstock is determined by a balance of its chemical composition, local availability, and cost, as these factors directly control the yield, quality, and economic viability of the entire process.

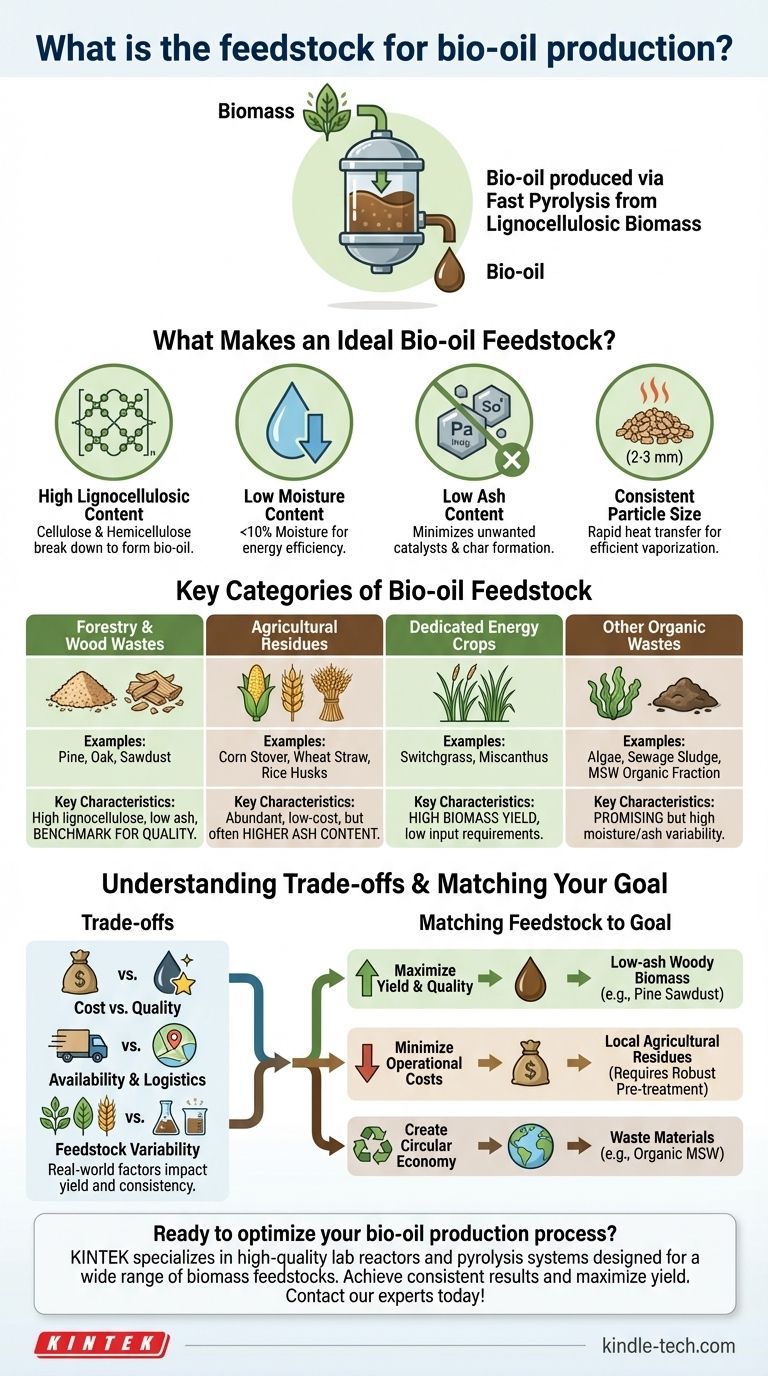

What Makes an Ideal Bio-oil Feedstock?

The selection of a feedstock is the single most important variable in bio-oil production. The process of fast pyrolysis is highly sensitive to the physical and chemical properties of the raw material being fed into the reactor.

High Lignocellulosic Content

The primary components of biomass that convert into liquid oil are cellulose and hemicellulose. These polymers break down under heat into the vapors that are condensed into bio-oil. Lignin also contributes, but it tends to produce a different, more complex set of compounds in the oil.

Low Moisture Content

Water in the feedstock must be evaporated before pyrolysis can occur, which consumes a significant amount of energy. A high moisture content lowers the overall energy efficiency of the process. Ideally, feedstock is dried to less than 10% moisture before being used.

Low Ash Content

Ash is the inorganic, non-combustible portion of biomass, containing minerals like potassium and sodium. These minerals can act as unwanted catalysts during pyrolysis, promoting reactions that produce more char and gas at the expense of the desired liquid bio-oil, thereby reducing your yield.

Consistent Particle Size

Efficient fast pyrolysis requires extremely rapid heat transfer. Small, uniform particles (typically less than 2-3 mm) have a high surface-area-to-volume ratio, allowing them to heat up almost instantly in the reactor. This ensures the biomass vaporizes quickly rather than slowly charring.

Key Categories of Bio-oil Feedstock

While the possibilities are vast, feedstocks are generally grouped into a few major categories based on their origin and characteristics.

Forestry and Wood Wastes

This is often considered the benchmark feedstock for bio-oil production. Materials like sawdust, wood chips, and bark from pine, oak, or poplar have high lignocellulose content and are naturally low in ash, leading to high-quality bio-oil yields.

Agricultural Residues

These are the materials left over after harvesting crops. Common examples include corn stover (stalks and leaves), wheat straw, and rice husks. They are incredibly abundant and low-cost, but often have a higher ash content than wood, which can present a technical challenge.

Dedicated Energy Crops

These are fast-growing, non-food plants cultivated specifically for biomass production. Perennial grasses like switchgrass and miscanthus are popular choices because they produce a high yield of biomass per acre with minimal agricultural inputs.

Other Organic Wastes

Research is ongoing for a wide variety of other feedstocks. This includes materials like sewage sludge, algae, and the organic fraction of municipal solid waste. While promising, they often present unique challenges related to high moisture, high ash content, and heterogeneity.

Understanding the Trade-offs

Choosing a feedstock is not a simple matter of finding the one with the best chemical profile. Real-world economics and logistics introduce critical trade-offs that must be managed.

Cost vs. Quality

The cheapest feedstocks are often waste products like agricultural residues. However, they may require more extensive pre-treatment (drying, grinding) and their higher ash content can lower oil yield and quality. Conversely, high-quality, uniform wood pellets produce excellent results but come at a much higher cost.

Availability and Logistics

Biomass is bulky and has a low energy density, making long-distance transportation economically unfeasible. A bio-oil production facility must have a reliable, high-volume supply of feedstock within a limited radius. Seasonality is also a major concern for agricultural residues, requiring year-round storage solutions.

Feedstock Variability

The chemical composition of biomass can vary significantly based on species, growing conditions, and harvest time. This variability can lead to an inconsistent bio-oil product, which is a major challenge if the oil is intended for upgrading into a standardized fuel or chemical.

Matching Feedstock to Your Goal

Your choice of feedstock should be directly aligned with the primary objective of your operation.

- If your primary focus is maximizing bio-oil yield and quality: Choose a low-ash, low-moisture woody biomass like pine sawdust or specialized wood pellets.

- If your primary focus is minimizing operational costs: Utilize locally abundant, low-cost agricultural residues or other organic wastes, but invest in robust pre-treatment and processing technology.

- If your primary focus is creating a sustainable, circular economy: Prioritize waste materials that would otherwise end up in a landfill, turning a disposal problem into a valuable resource.

Ultimately, understanding the properties of your feedstock is the foundational step toward successfully producing bio-oil.

Summary Table:

| Feedstock Category | Key Examples | Key Characteristics |

|---|---|---|

| Forestry/Wood Wastes | Sawdust, Wood Chips | High lignocellulose, low ash, benchmark for quality |

| Agricultural Residues | Corn Stover, Wheat Straw | Abundant, low-cost, but often higher ash content |

| Dedicated Energy Crops | Switchgrass, Miscanthus | High biomass yield, low input requirements |

| Other Organic Wastes | Algae, Sewage Sludge | Promising but can have high moisture/ash variability |

Ready to optimize your bio-oil production process? The right feedstock is critical, but so is the right equipment. KINTEK specializes in high-quality lab reactors and pyrolysis systems designed for testing and processing a wide range of biomass feedstocks. Whether you're researching agricultural residues or scaling up with wood waste, our solutions help you achieve consistent results and maximize yield. Contact our experts today to discuss how we can support your specific laboratory and bio-oil production goals.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Evaporation Boat for Organic Matter

People Also Ask

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability

- How can you improve corrosion resistance? Extend Equipment Life with Proven Strategies

- What is titanium disadvantages and advantages? Weighing Performance vs. Cost for Your Project