At its core, flash pyrolysis is a thermal decomposition process that rapidly heats organic materials like biomass or plastic in an oxygen-free environment. Unlike slower methods, it uses extremely high heating rates and very short reaction times, specifically to maximize the production of liquid bio-oil.

The defining characteristic of flash pyrolysis is its focus on speed. By heating feedstock in seconds, it cracks long-chain molecules into valuable liquids before they can break down further into less desirable gases and solid char.

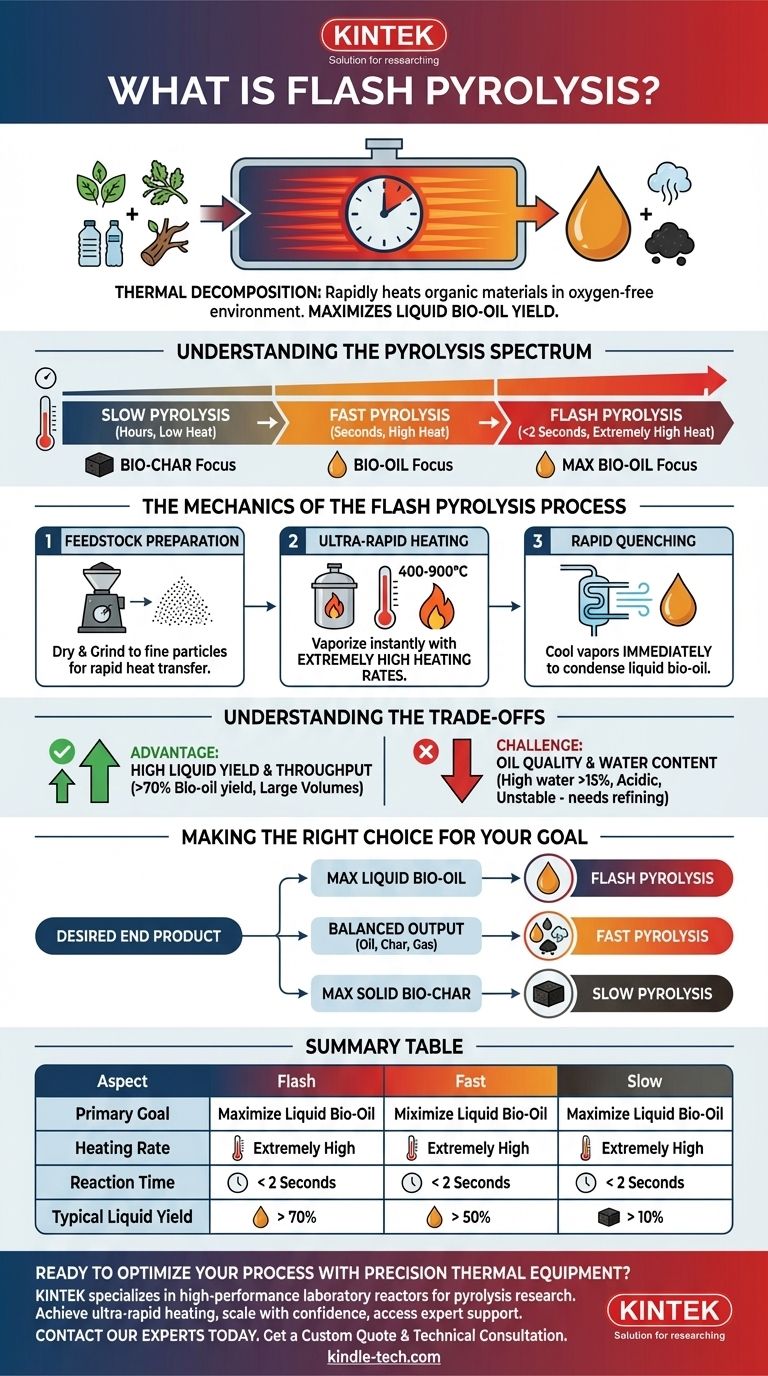

Understanding the Pyrolysis Spectrum

Pyrolysis is not a single process but a range of techniques defined by temperature, heating rate, and duration. The goal of the process dictates which method is used.

The Traditional Method: Slow Pyrolysis

Slow pyrolysis uses low heating rates over a long period (hours). This process is intentionally designed to break down material gently, maximizing the yield of the solid carbon-rich product known as bio-char. It produces the least amount of liquid oil.

A Faster Approach: Fast Pyrolysis

Fast pyrolysis increases the heating rate significantly, completing the process in seconds. This shifts the primary output from bio-char to bio-oil, creating a more balanced mix of liquid, solid, and gas products.

The Peak of Speed: Flash Pyrolysis

Flash pyrolysis represents the extreme end of the speed spectrum. It involves even higher heating rates and vapor residence times of less than two seconds. This ultra-rapid process is engineered almost exclusively to maximize the yield of liquid bio-oil.

The Mechanics of the Flash Pyrolysis Process

Achieving the speed necessary for flash pyrolysis requires precise control over several stages.

Step 1: Feedstock Preparation

The raw material, such as plastic or biomass, must be pre-treated. This involves drying the material and grinding it into very fine particles. Small particle size is essential for the rapid heat transfer needed for the "flash" effect.

Step 2: Ultra-Rapid Heating

The prepared feedstock is fed into a reactor and heated to temperatures between 400-900°C. The key, however, is not just the temperature but the extremely high heating rate. The goal is to vaporize the material almost instantly.

Step 3: Rapid Quenching

As soon as the hot vapors are formed, they must be cooled (quenched) immediately. This rapid cooling condenses the vapors into a liquid—the bio-oil—before they have a chance to undergo secondary reactions and break down into gas. This step is critical for maximizing liquid yield.

Understanding the Trade-offs

Flash pyrolysis offers significant advantages in throughput and liquid yield, but it also comes with specific challenges and product characteristics.

Advantage: High Liquid Yield and Throughput

The primary benefit is a high yield of bio-oil, often exceeding 70% by weight depending on the feedstock. Its rapid nature also allows for processing significantly larger volumes of material compared to slower methods.

Product Characteristic: High Water Content

Flash pyrolysis bio-oil is fundamentally different from conventional crude oil. As noted in research, it has a high water content, often over 15%. This water comes from the initial moisture in the feedstock and from the chemical decomposition reactions themselves.

The Challenge: Oil Quality

This bio-oil, sometimes called "pyrolytic tar," is also acidic, unstable, and viscous. It cannot be used directly in conventional engines or refineries and typically requires further upgrading or refining to become a usable fuel or chemical feedstock.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on your desired end product.

- If your primary focus is maximizing liquid fuel (bio-oil) production: Flash pyrolysis is the superior method due to its extremely high liquid yields.

- If your primary focus is creating bio-char for agriculture or carbon sequestration: Slow pyrolysis is the most effective and efficient process.

- If your primary focus is a balanced output of oil, char, and gas: Standard fast pyrolysis provides a versatile middle ground.

Ultimately, mastering thermal decomposition means choosing the right tool for the job based on a clear understanding of the final product you wish to create.

Summary Table:

| Aspect | Flash Pyrolysis | Fast Pyrolysis | Slow Pyrolysis |

|---|---|---|---|

| Primary Goal | Maximize Liquid Bio-Oil | Balanced Output (Oil, Char, Gas) | Maximize Solid Bio-Char |

| Heating Rate | Extremely High | High | Low |

| Reaction Time | < 2 Seconds | Seconds | Hours |

| Typical Liquid Yield | > 70% | Balanced | Lowest |

Ready to optimize your biomass or plastic conversion process with precision thermal equipment?

At KINTEK, we specialize in high-performance laboratory reactors and systems designed for advanced pyrolysis research and development. Whether you are developing next-generation biofuels or optimizing waste-to-energy processes, our equipment provides the precise control and reliability you need.

We help you:

- Achieve ultra-rapid heating rates for maximum bio-oil yield.

- Scale your process from lab to pilot with confidence.

- Access expert support for your specific feedstock and application.

Contact our thermal processing experts today to discuss how our solutions can accelerate your R&D and bring your projects to life.

Get a Custom Quote & Technical Consultation

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy