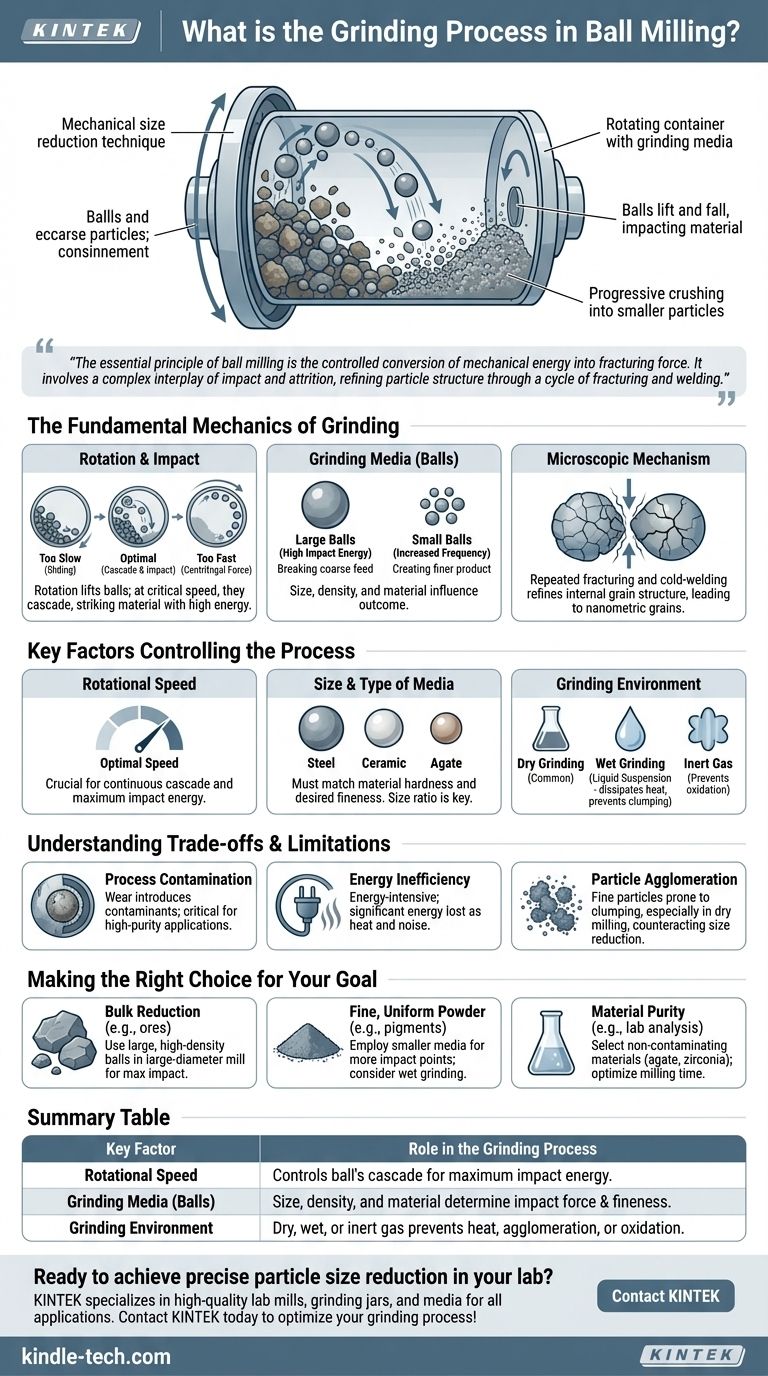

At its core, the grinding process in ball milling is a mechanical technique for reducing the size of solid materials. It works by placing the material into a rotating cylindrical container along with grinding media, typically hard balls. As the container rotates, the balls are lifted and then fall, repeatedly impacting and crushing the material into progressively smaller particles.

The essential principle of ball milling is the controlled conversion of mechanical energy into fracturing force. The process is not just simple crushing; it involves a complex interplay of impact and attrition from the grinding media, which refines particle structure through a repeated cycle of fracturing and welding.

The Fundamental Mechanics of Grinding

To truly understand the process, we must look at the forces at play and the components that create them. The effectiveness of the grind is determined by how these elements interact.

The Role of Rotation and Impact

The grinding action is generated by the rotation of the mill's container, often called a jar or drum. This rotation lifts the grinding balls and the material up the side of the container.

At a critical speed, the balls cascade or cataract back down, striking the material. This high-energy impact is the primary mechanism for breaking down coarse particles.

The Grinding Media (The Balls)

The balls are the active agents of size reduction. Their characteristics directly influence the outcome.

Large, heavy balls deliver more impact energy and are effective for breaking down large, coarse feed material. Smaller balls, in contrast, create a finer final product by reducing the empty spaces between particles and increasing the frequency of strikes.

The Microscopic Mechanism

On a microscopic level, the process is more complex than simple shattering. The mechanical energy from impacts induces a cycle of repeated fracturing and cold-welding.

This mechanism is what allows ball milling to refine the internal grain structure of particles, leading to the creation of nanometric-sized grains within larger micron-sized particles.

Key Factors Controlling the Process

The final particle size and distribution are not left to chance. They are controlled by carefully manipulating several key process variables.

Rotational Speed

The speed of the mill's rotation is critical. If the speed is too slow, the balls will simply slide down the material with minimal grinding action.

If the speed is too fast, the balls will be held against the container wall by centrifugal force, and no impacts will occur. The optimal speed ensures a continuous cascade of the balls, maximizing impact energy.

Size and Type of Grinding Media

The size, density, and material of the grinding balls must be matched to the material being processed.

As a rule, harder materials require harder grinding media. The size ratio between the balls and the particles is also crucial for efficient energy transfer and grinding.

The Grinding Environment

Grinding can be performed under different conditions depending on the desired outcome. Dry grinding is common, but wet grinding (in a liquid suspension) can help dissipate heat and prevent fine particles from clumping together.

For materials sensitive to air, the process can also be conducted in an inert gas atmosphere to prevent oxidation or other chemical reactions.

Understanding the Trade-offs and Limitations

While powerful, ball milling is not without its challenges. An objective assessment requires understanding its potential downsides.

Process Contamination

The constant impact and abrasion can cause wear on both the grinding media and the inner walls of the container. This wear can introduce contaminants into the material being milled.

This is a critical concern in high-purity applications, such as pharmaceuticals or advanced ceramics, where even trace contamination is unacceptable.

Energy Inefficiency

Ball milling is an energy-intensive process. A significant portion of the electrical energy consumed is converted into heat and noise rather than useful grinding action. This can make it costly for large-scale industrial operations.

Particle Agglomeration

As particles become extremely fine, their surface area increases dramatically, making them prone to clumping back together (agglomerating). This effect, especially prevalent in dry milling, can counteract the size-reduction process and make it difficult to achieve a truly nano-scale powder.

Making the Right Choice for Your Goal

To apply this process effectively, you must align the milling parameters with your specific objective.

- If your primary focus is bulk reduction of hard materials (e.g., ores): Use large, high-density steel or ceramic balls in a large-diameter mill to maximize the impact force of each collision.

- If your primary focus is producing a fine, uniform powder (e.g., pigments or ceramics): Employ smaller grinding media to increase the number of impact points and consider wet grinding to prevent particle agglomeration.

- If your primary focus is maintaining material purity (e.g., for lab analysis): Select grinding jars and media made of a non-contaminating material (like agate or zirconia) and carefully optimize milling time to minimize wear.

By understanding and controlling these mechanical forces, you can precisely tune the ball milling process to achieve the desired particle characteristics for nearly any application.

Summary Table:

| Key Factor | Role in the Grinding Process |

|---|---|

| Rotational Speed | Controls the ball's cascade for maximum impact energy. Too slow or too fast reduces efficiency. |

| Grinding Media (Balls) | Size, density, and material determine impact force and final particle fineness. |

| Grinding Environment | Dry, wet, or inert gas milling prevents heat, agglomeration, or material oxidation. |

Ready to achieve precise particle size reduction in your lab? The ball milling process is powerful, but getting the right results depends on using the right equipment. KINTEK specializes in high-quality lab mills, grinding jars, and media tailored for applications from coarse crushing to nano-scale powder creation. Our experts can help you select the perfect setup to ensure efficiency, purity, and consistency for your materials. Contact KINTEL today to optimize your grinding process!

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What are the disadvantages of planetary ball mill? Key Drawbacks in Energy, Noise, and Wear