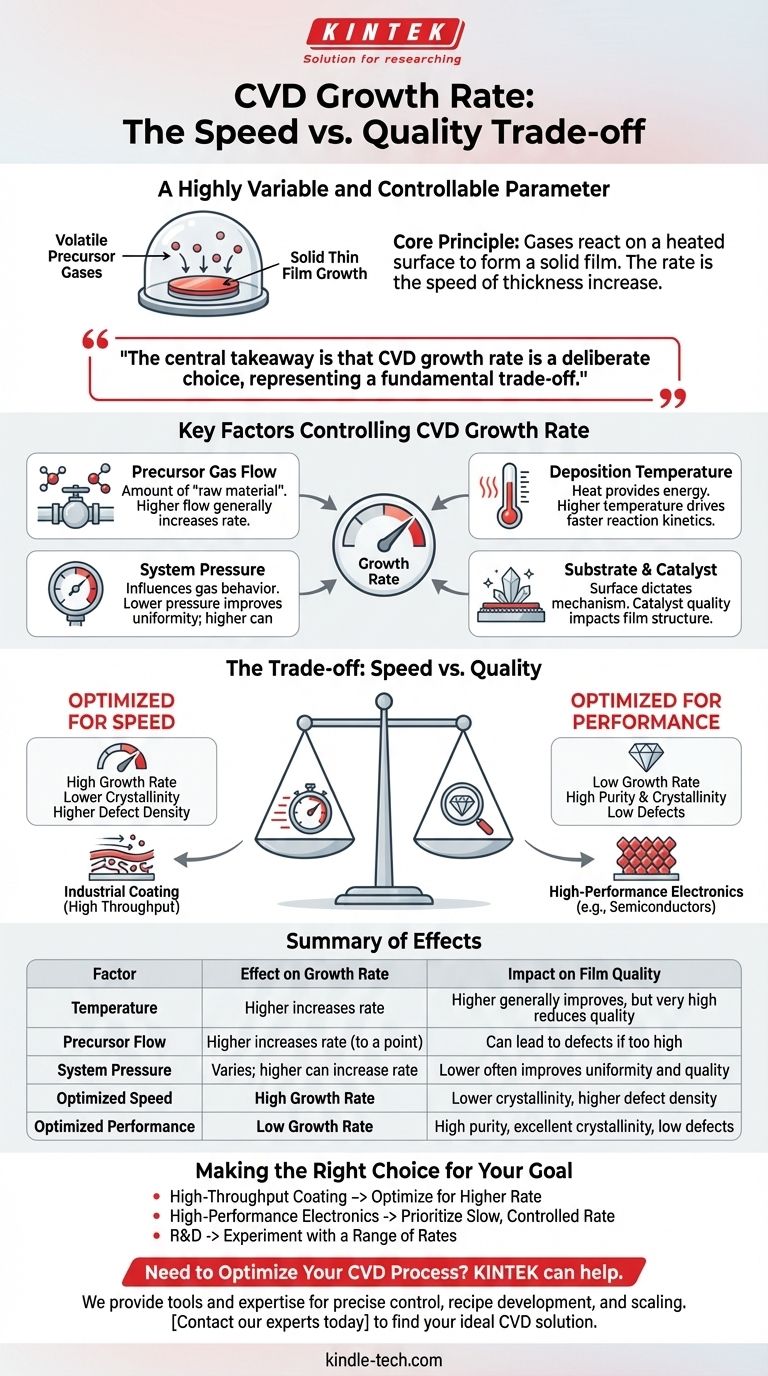

Critically, there is no single growth rate for Chemical Vapor Deposition (CVD). The rate is not a fixed property of the method but a highly variable and controllable parameter. It is intentionally adjusted based on the specific material being deposited, the equipment used, and—most importantly—the desired quality of the final film.

The central takeaway is that CVD growth rate is a deliberate choice, representing a fundamental trade-off. You can choose a high growth rate for speed and throughput, but this almost always comes at the cost of film quality, such as crystalline perfection and defect density.

The Core Principle of CVD Growth

Chemical Vapor Deposition is a process where volatile precursor gases are introduced into a reaction chamber. These gases decompose and react on the surface of a heated substrate, leaving behind a solid thin film. The "growth rate" is simply the speed at which this film's thickness (or area, for 2D materials like graphene) increases.

This rate is not accidental; it is precisely governed by several key process parameters.

Key Factors Controlling CVD Growth Rate

The ability to tune the growth rate is one of CVD's most powerful characteristics. Engineers and scientists carefully adjust a set of variables to achieve their target, whether that target is speed or perfection.

Precursor Gas Concentration and Flow

The amount of "raw material" available for the reaction is a primary controller. Increasing the concentration or flow rate of the precursor gases generally increases the deposition rate, but only up to a certain point where other factors become the bottleneck.

Deposition Temperature

Temperature is arguably the most critical parameter. As noted, CVD often requires very high temperatures (850-1100°C) because heat provides the necessary energy for the chemical reactions to occur.

Higher temperatures almost always lead to faster reaction kinetics and therefore a higher growth rate. This is a direct relationship: more thermal energy drives the surface reactions more quickly.

System Pressure

The pressure inside the reaction chamber influences the behavior of the gas molecules. Lowering the pressure can improve film uniformity but may slow the growth rate. Conversely, higher pressures can increase the rate but may negatively impact the quality and consistency of the film across the substrate.

Substrate and Catalyst

The surface on which the film grows plays a vital role. For a process like graphene synthesis, the choice of a metal catalyst (like copper or nickel) fundamentally dictates the growth mechanism and achievable rate. The catalyst's quality and crystal orientation directly impact the quality of the deposited film.

Understanding the Trade-offs: Speed vs. Quality

The decision to optimize for a specific growth rate is never made in a vacuum. It is always a balance between manufacturing efficiency and the performance requirements of the final product.

Why Faster Isn't Always Better

Pushing the growth rate too high by aggressively increasing temperature or precursor flow has significant consequences. Atoms arriving at the surface don't have enough time to find their ideal, low-energy positions in the crystal lattice.

This rushed process leads to a film with higher defect density, smaller crystal grains, and poor uniformity. For applications like high-performance electronics mentioned in the references, such defects would render the material useless.

Why Slower is Often Essential

For demanding applications that require pristine, single-crystal, or large-grain polycrystalline films, a slow and deliberate growth rate is non-negotiable.

A slower rate allows atoms to migrate across the surface and settle into the correct crystallographic sites. This results in the high-purity, low-defect, and well-crystallized films that make CVD a leading method for advanced materials.

Making the Right Choice for Your Goal

The optimal growth rate is entirely dependent on your end-use application.

- If your primary focus is high-throughput industrial coating: You would likely optimize for a higher growth rate, accepting a less-perfect amorphous or polycrystalline structure in exchange for speed and lower cost.

- If your primary focus is fabricating high-performance electronics: You must prioritize a slow, controlled growth rate to achieve the near-perfect crystalline quality and low defect density essential for device performance.

- If your primary focus is research and development: You will experiment with a wide range of growth rates to understand how they influence the material's fundamental properties.

Ultimately, mastering CVD is about understanding how to manipulate its parameters to achieve a specific outcome on the spectrum between speed and perfection.

Summary Table:

| Factor | Effect on Growth Rate | Impact on Film Quality |

|---|---|---|

| Temperature | Higher temperature increases rate | Higher temp generally improves quality, but very high rates can reduce it |

| Precursor Flow/Concentration | Higher flow/concentration increases rate (to a point) | Can lead to defects and non-uniformity if too high |

| System Pressure | Varies; higher pressure can increase rate | Lower pressure often improves uniformity and quality |

| Optimized for Speed | High Growth Rate | Lower crystallinity, higher defect density |

| Optimized for Performance | Low Growth Rate | High purity, excellent crystallinity, low defects |

Need to Optimize Your CVD Process for the Perfect Balance of Speed and Quality?

The right growth rate is critical for your project's success, whether you're in high-throughput manufacturing or cutting-edge R&D. KINTEK specializes in providing the lab equipment and expert support to help you master your CVD parameters.

We provide the tools and expertise to help you:

- Achieve precise control over temperature, pressure, and gas flow.

- Develop recipes that deliver the film quality your application demands.

- Scale your process efficiently from research to production.

Let's discuss your specific materials and goals. Contact our experts today to find the ideal CVD solution for your laboratory needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty