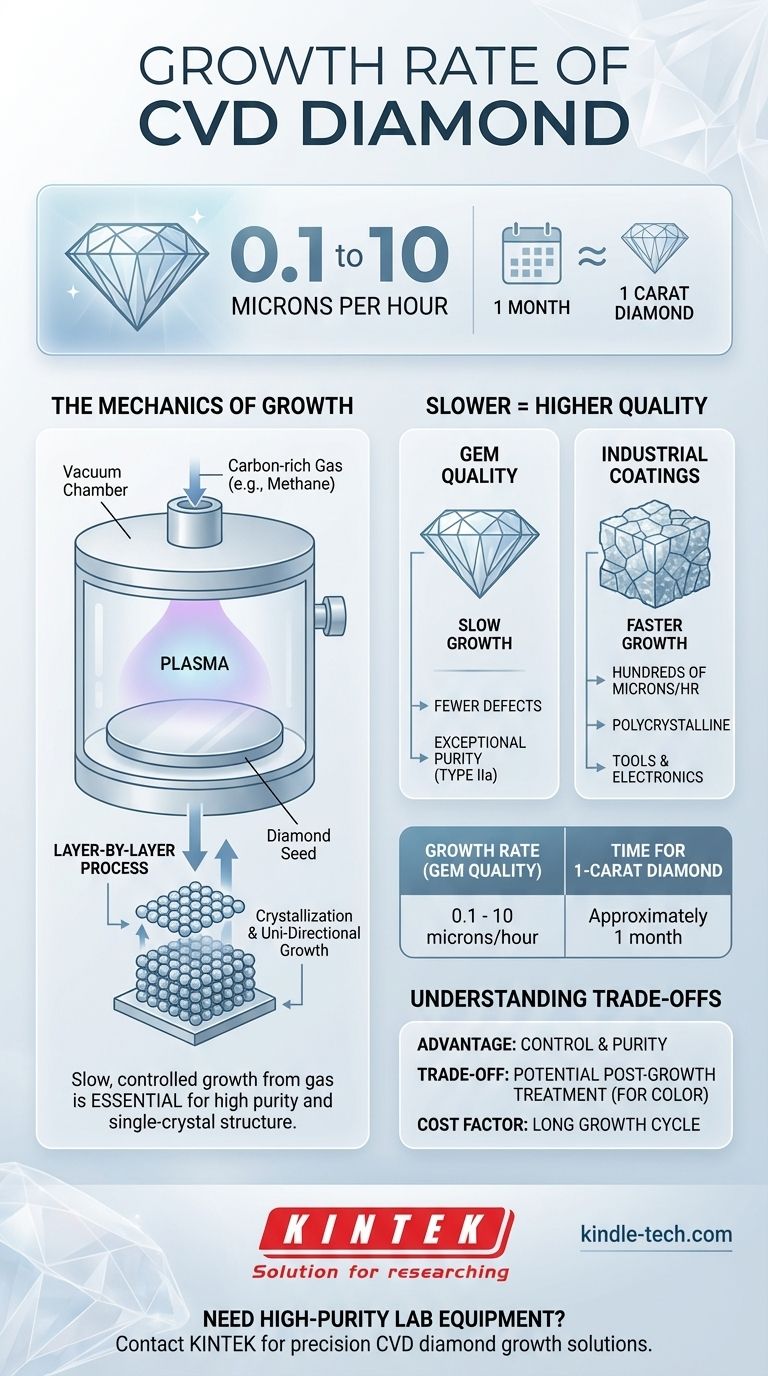

The growth rate of a CVD diamond is an exceptionally slow and meticulous process, typically ranging from 0.1 to 10 microns per hour for larger, gem-quality surfaces. This deliberate, layer-by-layer method of crystallization from a carbon-rich gas means that producing a single one-carat CVD diamond often takes about a month.

The slow, controlled growth of a Chemical Vapor Deposition (CVD) diamond is not a flaw but a fundamental requirement for achieving high purity and a strong, single-crystal structure. This deliberate pace is the key to creating a high-quality gemstone from gas.

The Mechanics of CVD Diamond Growth

To understand the growth rate, you must first understand the process. The CVD method is fundamentally different from the high-pressure, high-temperature (HPHT) technique, which mimics the earth's natural process.

The Core Principle: From Gas to Crystal

The process begins by placing a small, flat diamond "seed" inside a vacuum chamber. This chamber is then filled with a carbon-containing gas, such as methane.

By carefully controlling temperature and pressure, the gas is broken down, allowing carbon atoms to separate and gradually deposit, or crystallize, onto the diamond seed below.

A Layer-by-Layer Process

The growth is not a rapid formation but a slow, methodical accumulation. Carbon atoms attach to the seed layer by layer, building the diamond crystal upwards in a highly controlled manner.

This precision is what allows for the creation of diamonds with high purity and fewer internal defects compared to materials made with conventional ceramic fabrication processes.

The Uni-Directional Growth Pattern

CVD diamonds grow in a single direction, expanding vertically from the flat seed plate. This results in a characteristic cubic or tabular rough diamond shape.

While this uni-directional growth can occasionally create internal strain lines, these are typically rare and only visible under extremely high magnification.

Deconstructing the Growth Rate

The specific rate of growth is the most critical variable determining the quality and production time of the final diamond.

The Standard Rate for Gem Quality

For high-quality, single-crystal diamonds suitable for jewelry, the growth rate is very slow, falling within the 0.1 to 10 microns per hour range. A micron is one-millionth of a meter.

Why Slower is Better

This deliberate pace is essential for quality control. Attempting to grow the diamond too quickly can introduce defects, inclusions, or cause the formation of a less desirable polycrystalline structure instead of a single, coherent crystal.

A Note on Industrial Coatings

Some sources may cite much faster CVD rates, sometimes in the range of a few hundred microns per hour. It is critical to understand this refers to a different application.

These faster rates are used for depositing thin, hard, polycrystalline diamond coatings on industrial tools or electronics, not for growing large, gem-quality single crystals.

From Microns to Carats

The microscopic growth rate has a very real macroscopic impact. The slow and steady accumulation of microns is why it takes approximately one full month to grow a one-carat CVD diamond.

Understanding the Trade-offs

The slow growth rate is part of a series of trade-offs inherent to the CVD method, impacting the final product's characteristics and cost.

The Advantage of Control

The primary advantage of this slow process is control. It allows producers to create exceptionally pure and hard diamonds.

The Need for Post-Growth Treatment

A common trade-off is color. The conditions in a CVD reactor can sometimes result in a diamond with a brownish or grayish tint.

Because of this, many CVD diamonds undergo a post-growth treatment (often a form of HPHT annealing) to permanently improve their color and clarity.

Lower Upfront, Higher Runtime

While the equipment for the CVD process generally has a lower upfront cost than HPHT presses, the month-long growth cycle is an intensive, time-consuming process that contributes significantly to the final cost of the stone.

How This Impacts Your Choice

Understanding the growth rate provides direct insight into the final product's characteristics and the technology behind it.

- If your primary focus is on purity: The slow, controlled CVD growth rate is a significant advantage, often leading to very high-purity Type IIa diamonds.

- If you are concerned about potential treatments: Be aware that the specifics of the CVD process can necessitate post-growth color enhancement to achieve a colorless grade.

- If you are comparing lab-grown methods: Recognize that the CVD growth time is a major factor in its production scale and cost structure compared to the often faster, batch-oriented HPHT method.

Ultimately, the methodical and unhurried pace of the CVD process is precisely what allows for the creation of an exceptionally pure and well-formed diamond from simple gas.

Summary Table:

| Growth Rate (Gem Quality) | Time for 1-Carat Diamond | Key Factor |

|---|---|---|

| 0.1 - 10 microns per hour | Approximately 1 month | High purity & single-crystal structure |

Need High-Purity Lab Equipment for Your Diamond Research or Production?

The meticulous CVD diamond growth process demands precision and reliability. KINTEK specializes in providing the high-quality lab equipment and consumables essential for consistent, controlled environments. Whether you are developing new CVD processes or scaling production, our solutions support the precision your work requires.

Contact our experts today to discuss how we can equip your lab for success.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- CVD Diamond for Thermal Management Applications

People Also Ask

- What's the difference between CVD and HPHT? Choosing the Right Lab-Grown Diamond Method

- What is the difference between RF and microwave plasma? Choose the Right Plasma for Your Process

- Are lab-grown diamonds less durable than natural diamonds? They're Identical in Hardness and Resilience

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application

- Do lab grown diamonds pass a diamond tester? Yes, They're Chemically Identical.

- What are the physical characteristics of synthetic diamonds? Identical to Natural Diamonds, Made in a Lab

- What is CVD diamond technology? Grow High-Quality, Engineered Diamonds for Your Applications

- Are all lab grown diamonds CVD? Understanding the Two Main Methods