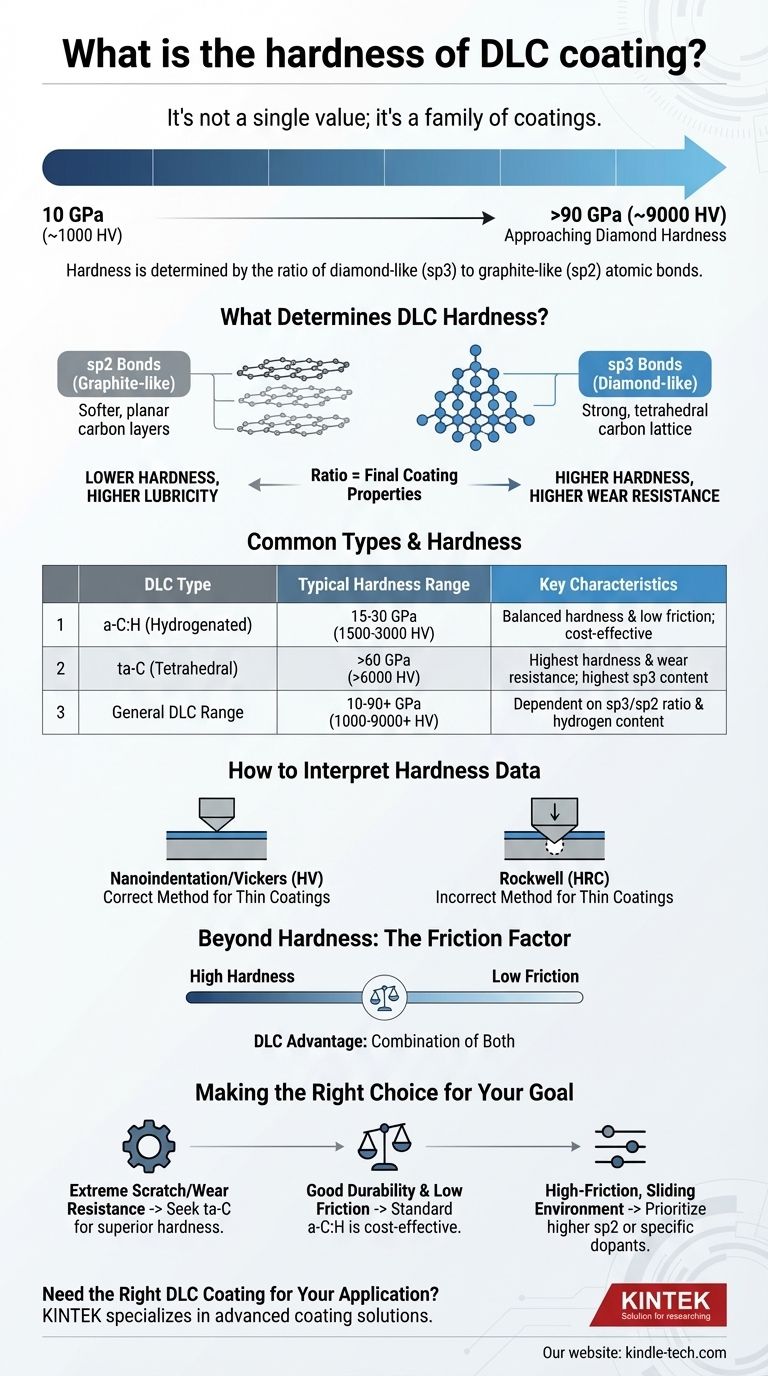

The hardness of a DLC coating is not a single value. Instead, it varies significantly depending on the specific type of Diamond-Like Carbon, ranging from approximately 10 GPa (around 1000 HV) to over 90 GPa (around 9000 HV), approaching the hardness of natural diamond.

The most critical takeaway is that "DLC" is a family of coatings, not a single material. Its final hardness is determined by the ratio of diamond-like (sp3) to graphite-like (sp2) atomic bonds, which can be engineered for different applications.

What Determines DLC Hardness?

The term Diamond-Like Carbon covers a broad range of amorphous carbon films. The variation in hardness stems directly from the coating's atomic structure and composition, which is controlled by the manufacturing process.

The Role of sp3 vs. sp2 Carbon Bonds

At its core, DLC is a mix of two types of carbon bonds. sp3 bonds are the strong, tetrahedral bonds that give diamond its extreme hardness. sp2 bonds are the planar bonds found in graphite, which are softer and provide lubricity.

A higher percentage of sp3 bonds results in a harder, more wear-resistant coating. A higher percentage of sp2 bonds leads to a coating with a lower coefficient of friction but less absolute hardness.

Common Types and Their Hardness

The most common form is hydrogenated amorphous carbon (a-C:H). It offers a great balance of hardness and low friction, typically falling in the 15-30 GPa (1500-3000 HV) range.

The hardest form is tetrahedral amorphous carbon (ta-C). This type has the highest concentration of sp3 bonds (up to 85%) and contains no hydrogen. Its hardness can exceed 60 GPa (6000 HV), making it exceptionally resistant to abrasive wear.

How to Interpret Hardness Data

Simply knowing the hardness number is not enough. You must understand how it's measured and what it means in the context of the coating's other properties.

Measurement: Nanoindentation vs. Rockwell

Standard hardness tests like Rockwell (HRC) are designed for bulk materials and will simply punch through a thin coating.

DLC hardness is properly measured using nanoindentation or Vickers microhardness (HV). These tests use a very small indenter and light loads to measure the properties of the coating itself, not the substrate beneath it.

Beyond Hardness: The Friction Factor

The true advantage of many DLC coatings is not just hardness, but the combination of high hardness and an extremely low coefficient of friction.

While other hard coatings like TiN or ZrN are very durable, they do not possess the inherent lubricity of DLC. This makes DLC uniquely suited for sliding components, bearings, and cutting tools where both wear and friction are critical concerns.

Understanding the Trade-offs

Selecting a DLC coating involves balancing performance, cost, and application constraints. There is no single "best" type for all situations.

Cost vs. Performance

Generally, harder coatings with higher sp3 content are more complex and expensive to deposit. A standard a-C:H coating is often a cost-effective solution for general-purpose wear and friction reduction.

High-performance ta-C coatings are reserved for applications where maximum durability is required and the higher cost can be justified.

Adhesion and Substrate Compatibility

A coating is only as effective as its bond to the part. Proper surface preparation of the substrate is absolutely critical to ensure strong adhesion and prevent the coating from flaking or chipping under load.

Temperature Limitations

Most DLC coatings, particularly hydrogenated types, begin to degrade at temperatures above 350°C (662°F). If your application involves high heat, you must select a specific high-temperature variant of DLC or consider a different ceramic coating altogether.

Making the Right Choice for Your Goal

Your application's specific demands should dictate your choice of coating.

- If your primary focus is extreme scratch and wear resistance: Seek a non-hydrogenated tetrahedral amorphous carbon (ta-C) coating for its superior hardness.

- If your primary focus is a balance of good durability and low friction: A standard hydrogenated amorphous carbon (a-C:H) provides an excellent, cost-effective solution.

- If you are coating parts in a high-friction, sliding environment: Prioritize a DLC formulation with a higher sp2 content or specific dopants designed for maximum lubricity.

Ultimately, choosing the right coating requires understanding that its properties are a carefully engineered balance for a specific purpose.

Summary Table:

| DLC Type | Typical Hardness Range | Key Characteristics |

|---|---|---|

| a-C:H (Hydrogenated) | 15-30 GPa (1500-3000 HV) | Good balance of hardness and low friction; cost-effective |

| ta-C (Tetrahedral) | >60 GPa (>6000 HV) | Highest hardness & wear resistance; highest sp3 bond content |

| General DLC Range | 10-90+ GPa (1000-9000+ HV) | Hardness depends on sp3/sp2 bond ratio and hydrogen content |

Need the Right DLC Coating for Your Application?

Selecting the correct DLC coating is critical for achieving optimal performance in terms of hardness, wear resistance, and friction reduction. The experts at KINTEK specialize in lab equipment and consumables, including advanced coating solutions for laboratory and industrial components.

We can help you:

- Identify the ideal DLC type (a-C:H, ta-C, etc.) for your specific wear, friction, and environmental requirements.

- Ensure proper substrate preparation for maximum coating adhesion and longevity.

- Navigate the trade-offs between performance, cost, and temperature limitations.

Contact us today via our contact form to discuss how our coating expertise can enhance the durability and efficiency of your laboratory equipment and components.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

People Also Ask

- What is Plasma-enhanced CVD (PECVD)? The Critical Benefits for CMOS Fabrication and Thin Film Quality

- How does plasma deposition work? Enable Low-Temperature Thin Film Coating for Sensitive Materials

- What are the common applications of PECVD systems in the semiconductor industry? Enhance Your Thin-Film Fabrication

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is the temperature at which the PECVD is carried out? Optimize Your Thin Film Deposition Process

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What are the different types of plasma sources? A Guide to DC, RF, and Microwave Technologies

- What is the process of PACVD? Achieve High-Quality Coatings at Lower Temperatures