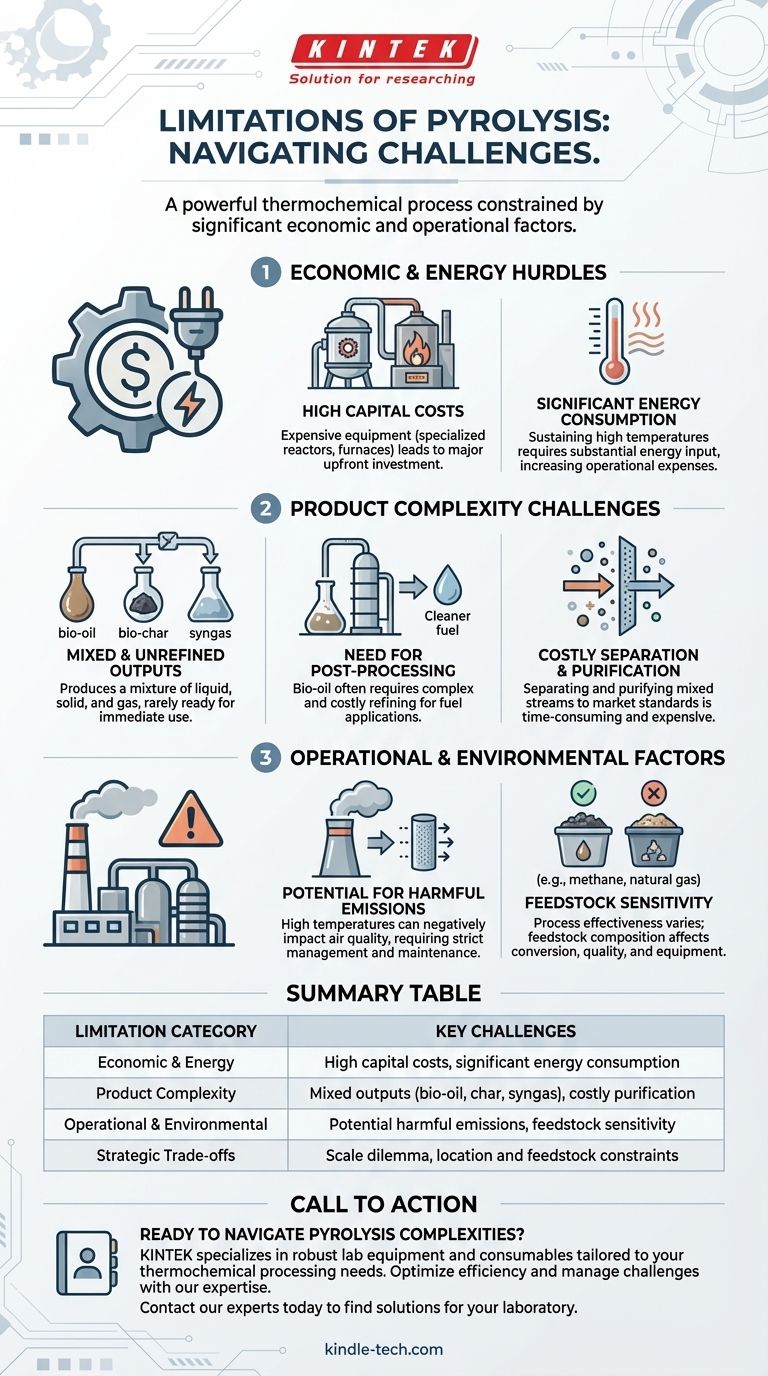

While a powerful thermochemical process, the practical application of pyrolysis is constrained by significant economic and operational challenges. The primary limitations include high capital and energy costs, the necessity for costly separation and purification of its mixed end-products, and the potential for harmful air emissions if not managed meticulously.

Pyrolysis is not a simple "plug-and-play" solution. Its viability hinges on overcoming substantial financial hurdles and managing complex technical requirements, from high energy input to the extensive post-processing of its outputs.

The Economic and Energy Hurdles

The most immediate barriers to widespread pyrolysis adoption are financial and energetic. The process is inherently resource-intensive, which directly impacts its cost-effectiveness.

High Capital Costs

The equipment required for pyrolysis, such as specialized reactors and furnaces capable of maintaining high temperatures in an oxygen-free environment, is expensive to manufacture and install. These high upfront capital costs can be a major deterrent.

Significant Energy Consumption

Pyrolysis functions by breaking down materials at very high temperatures. Achieving and sustaining these temperatures, often for long residence times, demands a substantial amount of energy, which increases operational expenses.

The Challenge of Product Complexity

Unlike processes that yield a single, refined product, pyrolysis creates a mixture of substances that require further handling, adding layers of complexity and cost.

Mixed and Unrefined Outputs

The process simultaneously produces a liquid (bio-oil), a solid (bio-char), and a gas (syngas). This mixed stream is rarely ready for immediate use.

The Need for Post-Processing

The bio-oil, a key output, often requires significant refining before it can be used as a transportation fuel. This extra step is both technically complex and expensive.

Costly Separation and Purification

Separating the oil, char, and gas from one another and purifying them to meet market or application standards is a time-consuming and costly phase of the overall process.

Operational and Environmental Considerations

Beyond cost, the day-to-day operation of a pyrolysis system presents its own set of challenges that must be carefully managed to ensure safety and environmental compliance.

Potential for Harmful Emissions

The high temperatures involved can produce emissions that negatively impact air quality. Mitigating this risk requires proper design, diligent operation, and consistent maintenance of the system to keep it environmentally sound.

Feedstock Sensitivity

The process is not universally effective for all materials. The composition of the feedstock is critical; for example, results from pyrolyzing pure methane do not directly apply to natural gas, which contains impurities that alter conversion rates, product quality, and can even damage equipment.

Understanding the Trade-offs

The limitations of pyrolysis create a series of trade-offs that determine its suitability for any given application. Ignoring these can lead to inefficient or failed projects.

The Scale Dilemma

Due to the high capital investment and the need for extensive product refining, pyrolysis is often less cost-effective for small-scale applications. It typically requires a large, consistent volume of feedstock to become financially viable.

Location and Feedstock Constraints

The success of a pyrolysis plant can depend heavily on its location and the specific type of feedstock available. A mismatch between the technology and the available raw material can render the process unsuitable or inefficient.

Making the Right Choice for Your Goal

To determine if pyrolysis is the correct approach, you must align its capabilities with your primary objective.

- If your primary focus is large-scale waste-to-value conversion: The high capital and operational costs must be carefully weighed against the market value of the refined end-products.

- If your primary focus is producing a specific high-quality fuel: Be prepared to invest heavily in downstream separation, purification, and refining technologies.

- If your primary focus is environmental sustainability: Prioritize investment in advanced emission control systems and rigorous operational maintenance to ensure the process is genuinely beneficial.

Understanding these inherent limitations is the first and most critical step toward successfully harnessing the potential of pyrolysis.

Summary Table:

| Limitation Category | Key Challenges |

|---|---|

| Economic & Energy | High capital costs, significant energy consumption |

| Product Complexity | Mixed outputs (bio-oil, char, syngas), costly purification |

| Operational & Environmental | Potential harmful emissions, feedstock sensitivity |

| Strategic Trade-offs | Scale dilemma, location and feedstock constraints |

Ready to navigate the complexities of pyrolysis for your lab?

Understanding the limitations of pyrolysis is crucial for a successful project. At KINTEK, we specialize in providing robust lab equipment and consumables tailored to your thermochemical processing needs. Whether you're scaling up or refining your process, our expertise can help you optimize efficiency and manage operational challenges.

Let's discuss your specific application. Contact our experts today to find the right solutions for your laboratory's pyrolysis and broader research goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance