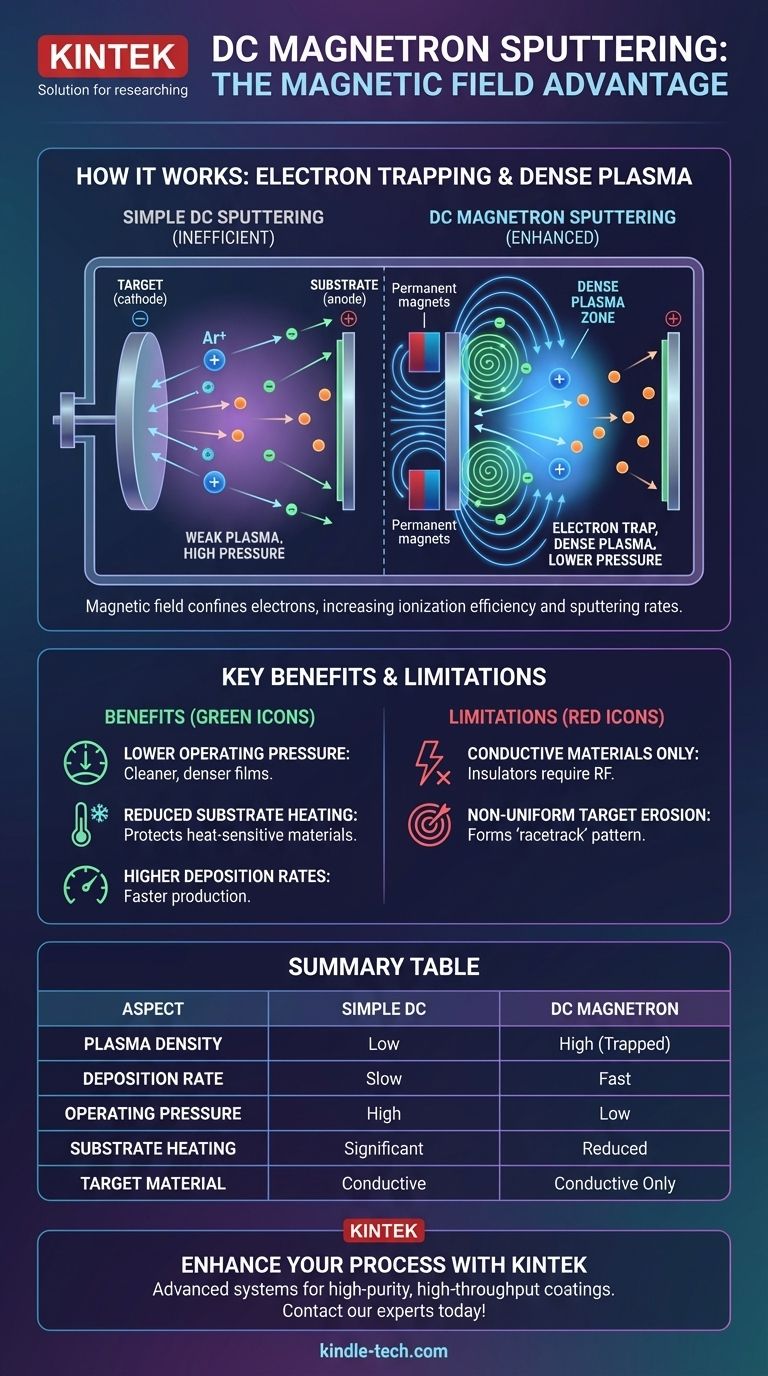

In DC magnetron sputtering, the magnetic field is a critical enhancement that dramatically increases the efficiency of the thin-film deposition process. It functions by creating a magnetic "trap" for electrons near the surface of the material being deposited (the target). This confinement intensifies the plasma responsible for sputtering, leading to faster, more controlled deposition rates while protecting the substrate from unwanted energy bombardment.

The fundamental problem with simple DC sputtering is its low efficiency and high operating pressure. The magnetic field in a magnetron system solves this by acting as an electron trap, creating a dense, localized plasma that significantly increases sputtering rates and allows for lower process pressures, all while protecting the substrate from damaging heat.

The Foundation: How DC Sputtering Works

DC sputtering is a type of Physical Vapor Deposition (PVD) that occurs in a vacuum chamber. The goal is to transfer atoms from a source material onto a substrate to form a thin film.

The Basic Setup: Target, Substrate, and Gas

The system consists of a target (the material to be deposited) which is given a large negative DC voltage, making it the cathode. The object to be coated, the substrate, acts as the anode. The chamber is filled with a small amount of an inert gas, typically Argon (Ar).

The Bombardment Process

The high negative voltage on the target attracts positively charged Argon ions (Ar+) from the surrounding gas. These ions accelerate and collide with the target surface with significant energy.

This bombardment physically knocks out, or "sputters," atoms from the target material. These newly freed atoms travel through the vacuum and condense on the substrate, gradually building a thin, uniform film.

The Limitation of Simple DC Sputtering

Without a magnetic field, this process is inefficient. The plasma is weak, and many of the secondary electrons released from the target during bombardment travel directly to the substrate or chamber walls without causing further ionization. This requires higher gas pressures to sustain the plasma, which can lead to gas incorporation and impurities in the final film.

The "Magnetron" Advantage: Adding the Magnetic Field

The introduction of a magnetron—a configuration of permanent magnets placed behind the target—is what elevates the process to magnetron sputtering.

Creating an Electron Trap

The magnets generate a field that is parallel to the target's surface. This magnetic field does not significantly affect the heavy Argon ions, but it has a profound effect on the light secondary electrons that are also ejected from the target during bombardment.

The field forces these electrons into a spiral trajectory, effectively trapping them in a zone close to the target surface. Instead of escaping, they travel a much longer path.

The Impact on Plasma Density

Because the electrons are confined and travel a longer distance, the probability of them colliding with neutral Argon gas atoms increases dramatically. Each collision has the potential to ionize an Argon atom (Ar → Ar⁺ + e⁻).

This highly efficient ionization process creates a dense, self-sustaining plasma concentrated directly in front of the target.

The Result: Higher Sputtering Rates

This dense plasma contains a much higher concentration of Ar⁺ ions available to bombard the target. This directly leads to a significantly higher sputtering rate, meaning films can be deposited much faster than with simple DC sputtering.

Understanding the Key Benefits and Trade-offs

The magnetic field enhancement provides several distinct advantages, but it's also important to understand its limitations.

Benefit: Lower Operating Pressure

Because the magnetic field makes ionization so efficient, the plasma can be sustained at much lower gas pressures. This reduces the chance of sputtered atoms colliding with gas atoms on their way to the substrate, resulting in a cleaner, denser, and higher-purity film.

Benefit: Reduced Substrate Heating

By trapping electrons near the target, the magnetic field prevents them from bombarding the substrate. This significantly reduces the heat load on the part being coated, making the process suitable for temperature-sensitive materials like plastics and polymers.

Limitation: Conductive Materials Only

Standard DC magnetron sputtering requires the target material to be electrically conductive. An insulating (dielectric) target would accumulate a positive charge from ion bombardment, effectively neutralizing the negative bias and halting the sputtering process. For insulating materials, Radio Frequency (RF) sputtering is used instead.

Limitation: Non-Uniform Target Erosion

The area where the magnetic field traps the electrons forms a distinct "racetrack" pattern on the target's surface. Sputtering is most intense in this zone, leading to uneven erosion of the target material. This means only a fraction of the target material is consumed before it must be replaced.

Making the Right Choice for Your Application

DC magnetron sputtering is a powerful and widely used technique for thin-film deposition. Choosing it depends on your specific material and production goals.

- If your primary focus is high-throughput production of metallic coatings: DC magnetron sputtering is the ideal choice due to its exceptionally fast deposition rates and suitability for industrial automation.

- If your primary focus is depositing high-purity films with excellent adhesion: The ability to operate at lower pressures minimizes contamination and creates dense, well-bonded coatings.

- If you are working with heat-sensitive substrates: The confined plasma and reduced electron bombardment make this a far safer choice than deposition methods that generate significant heat.

Ultimately, understanding the role of the magnetic field transforms magnetron sputtering from a concept into a precise and powerful tool for engineering materials at the atomic level.

Summary Table:

| Aspect | Simple DC Sputtering | DC Magnetron Sputtering |

|---|---|---|

| Plasma Density | Low | High (due to magnetic confinement) |

| Deposition Rate | Slow | Fast |

| Operating Pressure | High | Low |

| Substrate Heating | Significant | Reduced |

| Target Material | Conductive | Conductive (only) |

Ready to enhance your thin-film deposition process? KINTEK specializes in advanced lab equipment, including DC magnetron sputtering systems designed for high-throughput production of high-purity metallic coatings. Our solutions deliver faster deposition rates and superior film quality while protecting temperature-sensitive substrates. Contact our experts today to find the perfect sputtering system for your laboratory's specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the raw materials for bio-oil? A Guide to Selecting the Best Biomass Feedstock

- What role does a laboratory homogenizer play in radioactive cesium detection? Ensure Accuracy in Wildlife Sampling

- What are the advantages of belt filter press? Achieve High-Volume Dewatering with Low Operational Cost

- What are the industrial applications of filtration? The Essential Guide to Separation Processes

- What are the dangers of heat in a lab? Protect Your Lab from Burns, Fires, and Data Loss

- What is the difference between VAR and ESR? A Guide to Understanding Tail Risk in Financial Modeling

- What is the method of thin film coating? A Guide to Wet vs. Dry Deposition

- Which metal is harder to melt? Tungsten Leads with the Highest Melting Point