The maximum temperature of a ceramic tube is not a single value; it depends entirely on the specific material composition. A transparent quartz tube, for example, has a maximum continuous use temperature of around 1100°C (2012°F), while a high-purity alumina tube can withstand over 1700°C (3092°F).

The term "ceramic" covers a vast family of materials with dramatically different properties. To determine a tube's maximum temperature, you must first identify the specific ceramic it is made from, as this is the single most important factor.

Why "Ceramic" Isn't Specific Enough

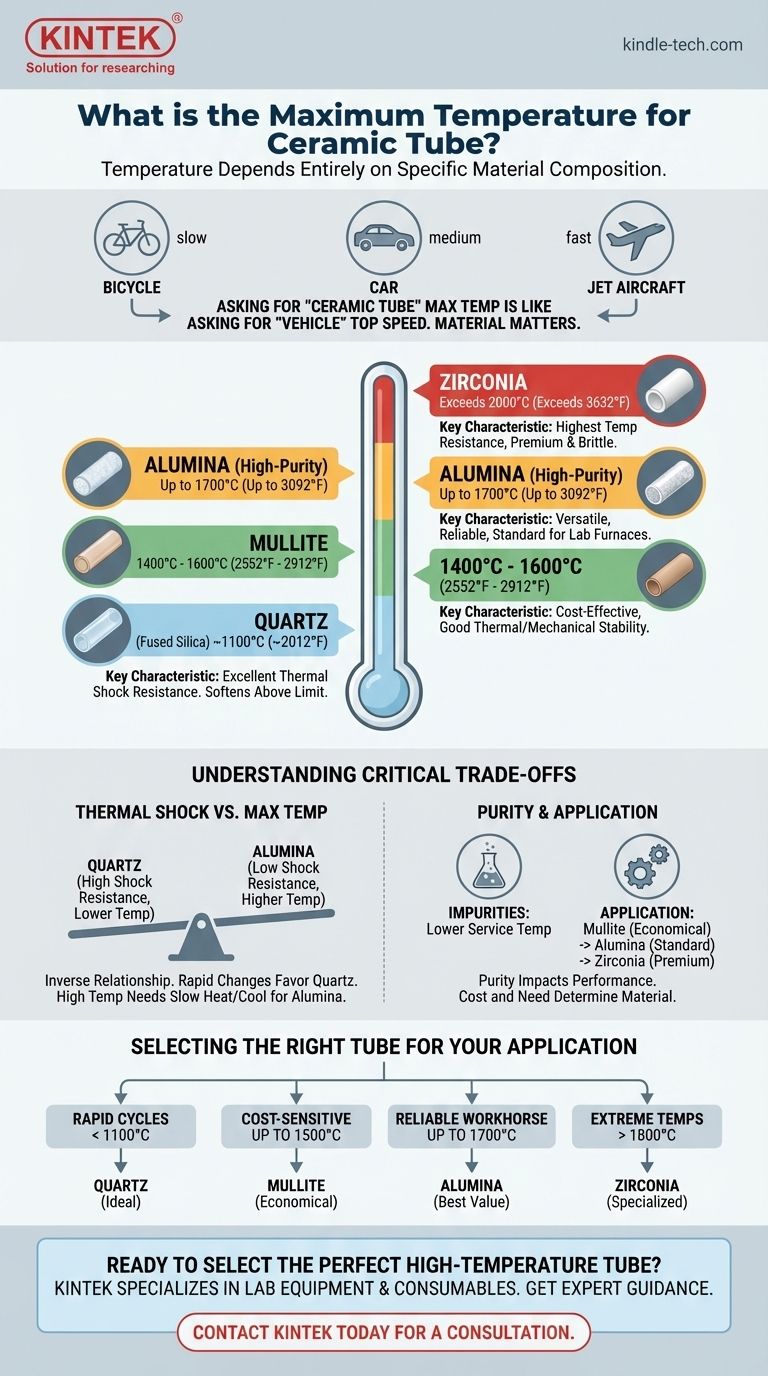

Asking for the maximum temperature of a "ceramic tube" is like asking for the top speed of a "vehicle." The answer is useless without knowing if we are discussing a bicycle, a car, or a jet aircraft.

Advanced ceramics used for high-temperature applications are engineered materials, each with a unique profile of strengths and weaknesses.

The Importance of Material Composition

Different chemical compositions yield vastly different thermal limits. Common materials like quartz are silica-based, while others like alumina are based on aluminum oxide, giving them fundamentally different performance ceilings.

A Breakdown of Common High-Temperature Ceramics

To select the correct tube, you must be familiar with the primary material options and their typical service temperatures.

Quartz (Fused Silica)

As noted, quartz is an excellent choice for applications requiring high thermal shock resistance.

Its maximum continuous operating temperature is approximately 1100°C (2012°F). Above this, it begins to soften and devitrify, losing its structural integrity.

Mullite

Mullite is a cost-effective aluminosilicate ceramic known for its good thermal and mechanical stability.

It is commonly used in furnace tubes and insulators with a maximum service temperature between 1400°C and 1600°C (2552°F - 2912°F).

Alumina (Aluminum Oxide, Al₂O₃)

Alumina is the most common and versatile technical ceramic for high-temperature structural applications. Its performance is directly tied to its purity.

A 99.8% pure alumina tube can reliably operate at temperatures up to 1700°C (3092°F), making it a standard for many lab and industrial furnaces.

Zirconia (Zirconium Dioxide, ZrO₂)

For the most extreme environments, Zirconia offers the highest temperature resistance among common ceramics.

Stabilized zirconia tubes can be used in applications exceeding 2000°C (3632°F), though they are significantly more expensive and brittle.

Understanding the Critical Trade-offs

Temperature resistance is only one part of the equation. Selecting the wrong material based on temperature alone can lead to catastrophic failure.

Thermal Shock vs. Max Temperature

There is often an inverse relationship between maximum temperature and thermal shock resistance. Quartz, with its lower temperature limit, can withstand extremely rapid temperature changes without cracking.

In contrast, high-purity Alumina must be heated and cooled slowly and controllably to prevent thermal stress fractures.

Purity and Contamination

The purity of a ceramic, especially Alumina, directly impacts its performance. Lower-purity grades have lower service temperatures because the impurities can melt and compromise the material's structure.

In a vacuum or reducing atmosphere, silica-based ceramics like quartz and mullite can become a source of contamination at high temperatures.

Cost and Application

The cost of these materials varies significantly. Mullite is generally the most economical, followed by Alumina. Quartz has a moderate cost, while Zirconia is a premium material reserved for the most demanding applications.

Selecting the Right Tube for Your Application

Your choice must be guided by a clear understanding of your operational requirements, not just a single temperature value.

- If your primary focus is rapid heating/cooling cycles below 1100°C: Quartz is the ideal and safest choice due to its superior thermal shock resistance.

- If you need a reliable workhorse for high-temperature furnace applications up to 1700°C: High-purity Alumina offers the best combination of performance and value.

- If you are building a cost-sensitive system for use up to 1500°C: Mullite provides excellent performance and is a highly economical solution.

- If your application involves extreme temperatures exceeding 1800°C: Zirconia is the specialized material required, provided you can manage its cost and mechanical fragility.

By matching the specific material to your unique operational conditions, you ensure a reliable, safe, and effective high-temperature system.

Summary Table:

| Material | Max Continuous Use Temperature (°C) | Max Continuous Use Temperature (°F) | Key Characteristics |

|---|---|---|---|

| Quartz (Fused Silica) | ~1100°C | ~2012°F | Excellent thermal shock resistance, softens above limit |

| Mullite | 1400°C - 1600°C | 2552°F - 2912°F | Cost-effective, good thermal/mechanical stability |

| Alumina (High-Purity) | Up to 1700°C | Up to 3092°F | Versatile, reliable, standard for many lab furnaces |

| Zirconia | Exceeds 2000°C | Exceeds 3632°F | Highest temperature resistance, premium & brittle |

Ready to Select the Perfect High-Temperature Tube?

Choosing the right ceramic tube is critical for the safety and performance of your lab equipment. The wrong material can lead to contamination, failure, and costly downtime.

KINTEK specializes in lab equipment and consumables, providing expert guidance and high-quality ceramic tubes tailored to your specific application—whether you need the thermal shock resistance of quartz, the high-temperature reliability of alumina, or the extreme heat capabilities of zirconia.

Let our experts help you make the right choice. Contact KINTEK today for a consultation and ensure your lab operates at peak efficiency and safety.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- Why use a tube furnace? Achieve Superior Temperature Uniformity and Atmosphere Control

- What are the hazards of a tube furnace? Beyond the Obvious Burn Risks

- How does an alumina tube furnace with a controlled atmosphere simulate conditions in CSP environments? Master Accuracy.