Sputter deposition is a physical vapor deposition (PVD) method where high-energy ions are used to bombard a source material, causing its atoms to be ejected or "sputtered." These ejected atoms then travel through a vacuum and deposit onto a substrate, forming an exceptionally thin and uniform film. It is less a process of melting and more a form of atomic-scale sandblasting.

At its core, sputtering is not a chemical reaction but a momentum transfer process. It uses energetic ions, typically from an inert gas like argon, to physically dislodge atoms from a target material and redeposit them, offering precise control over the composition of complex thin films.

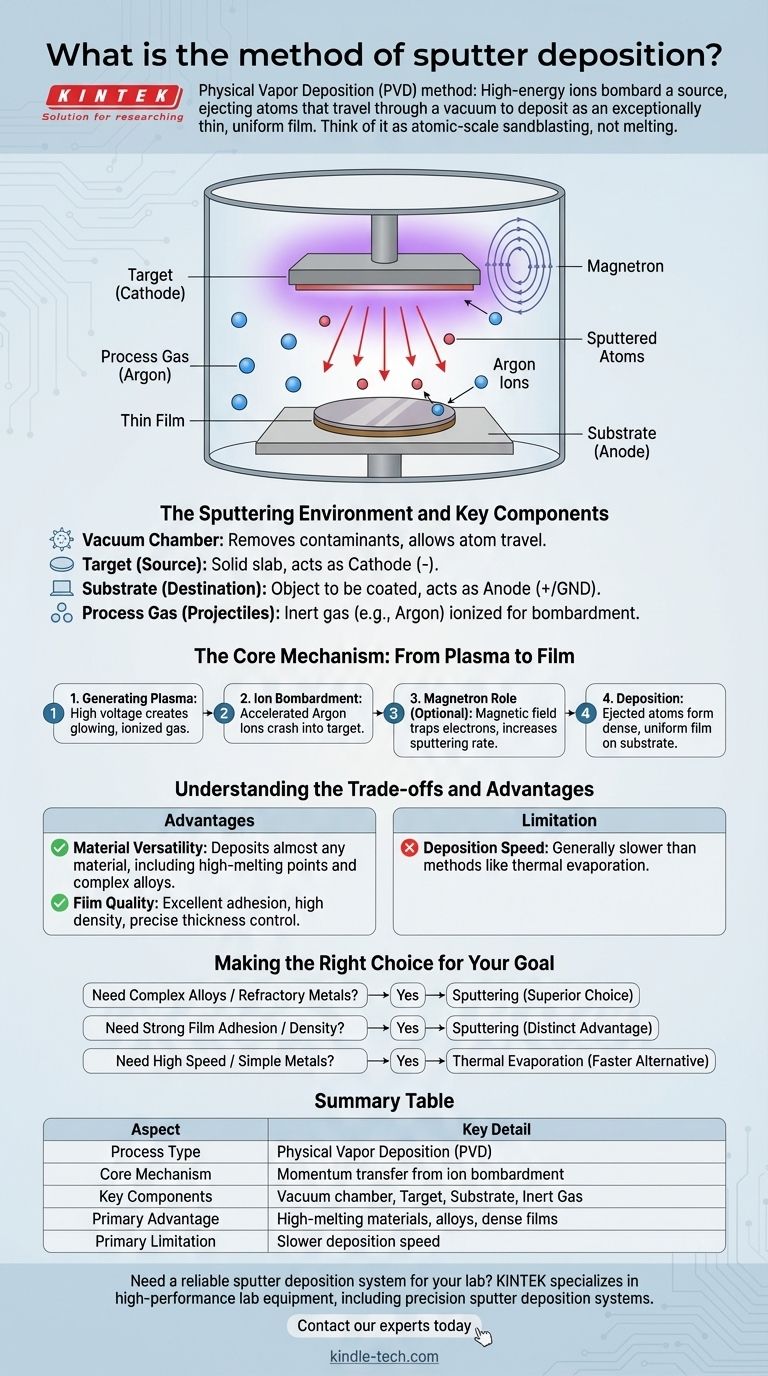

The Sputtering Environment and Key Components

To understand the method, you must first understand the highly controlled environment where it occurs. Every component plays a critical role in the final quality of the thin film.

The Vacuum Chamber

The entire process takes place inside an evacuable chamber. A high vacuum is essential to remove atmospheric contaminants and to allow the sputtered atoms to travel from the target to the substrate without colliding with other gas molecules.

The Target (The Source)

The target is a solid slab of the material you wish to deposit. In the system's electrical setup, the target functions as the cathode (negatively charged).

The Substrate (The Destination)

The substrate is the object or wafer that will be coated. It is placed on a holder that functions as the anode (grounded or positively charged).

The Process Gas (The Projectiles)

An inert gas, most commonly argon, is introduced into the chamber in small, controlled amounts. This gas is not part of the final film; its sole purpose is to be ionized and used as the "projectiles" to bombard the target.

The Core Mechanism: From Plasma to Film

The sputtering process is a sequence of events that transforms a solid target into a precise thin film.

Step 1: Generating the Plasma

A high voltage is applied between the cathode (target) and the anode (substrate). This powerful electric field energizes the argon gas, stripping electrons from the argon atoms and creating a plasma—a glowing, ionized gas consisting of positive argon ions and free electrons.

Step 2: Ion Bombardment

The positively charged argon ions in the plasma are accelerated by the electric field and crash into the negatively charged target surface with great force. This high-energy collision physically knocks atoms loose from the target material.

Step 3: The Role of Magnetrons

In modern systems, a technique called magnetron sputtering is used to improve efficiency. A magnetic field is applied near the target surface. This field traps the free electrons from the plasma, forcing them into a spiral path near the target, which drastically increases the number of collisions they have with argon atoms. This creates more argon ions, which in turn leads to a much higher rate of sputtering.

Step 4: Deposition

The sputtered atoms ejected from the target travel through the vacuum and impinge on the substrate. As they accumulate on the surface, they form a dense, thin, and highly uniform film.

Understanding the Trade-offs and Advantages

Sputtering is an incredibly powerful technique, but its strengths define its ideal applications. It is not always the right choice compared to other methods like chemical vapor deposition (CVD) or thermal evaporation.

Key Advantage: Material Versatility

Sputtering's primary strength is its ability to deposit almost any material. It is especially effective for materials with very high melting points (like tungsten or tantalum) and for complex alloys or compounds. Because the target is physically eroded rather than melted, the composition of the deposited film remains identical to the source material.

Key Advantage: Film Quality

The high kinetic energy of the sputtered atoms results in films with excellent adhesion to the substrate and high density. The process also provides very fine control over film thickness.

Primary Limitation: Deposition Speed

Generally, sputter deposition can be a slower process compared to other methods like thermal evaporation. The efficiency of knocking atoms off the target, known as the "sputter yield," dictates the overall speed, which can be a limiting factor in high-volume production.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the material properties and performance you need to achieve.

- If your primary focus is depositing complex alloys or refractory metals: Sputtering is the superior choice because it preserves the original material's composition without relying on high-temperature evaporation.

- If your primary focus is achieving strong film adhesion and density: The high energy of sputtered particles provides a distinct advantage, creating more durable and robust films than lower-energy processes.

- If your primary focus is coating large areas with simple metals at high speed: A process like thermal evaporation might be a more cost-effective and faster alternative.

Ultimately, sputter deposition provides an exceptional level of control for engineering high-performance thin films atom by atom.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer from ion bombardment |

| Key Components | Vacuum chamber, target (cathode), substrate (anode), inert gas (e.g., Argon) |

| Primary Advantage | Excellent for high-melting-point materials, alloys, and dense, adherent films |

| Primary Limitation | Generally slower deposition speed compared to methods like thermal evaporation |

Need a reliable sputter deposition system for your lab?

KINTEK specializes in high-performance lab equipment, including sputter deposition systems designed for precision and reliability. Whether you are working with complex alloys, refractory metals, or require films with superior adhesion, our solutions are tailored to meet the rigorous demands of laboratory research and development.

Contact our experts today to discuss how our sputtering technology can enhance your thin film applications and achieve your specific material science goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells