At its core, Microwave Plasma Enhanced Chemical Vapor Deposition (MPCVD) is an advanced process used to create high-purity, high-performance solid coatings. It refines traditional chemical vapor deposition by using microwave energy to generate a plasma, which provides the energy for chemical reactions. This allows for the deposition of materials at significantly lower temperatures than conventional methods require.

The crucial advantage of MPCVD is its ability to decouple the reaction energy from the substrate's temperature. By using microwaves to create a highly energetic plasma, it can grow superior quality films on materials that would be damaged by the extreme heat of traditional deposition processes.

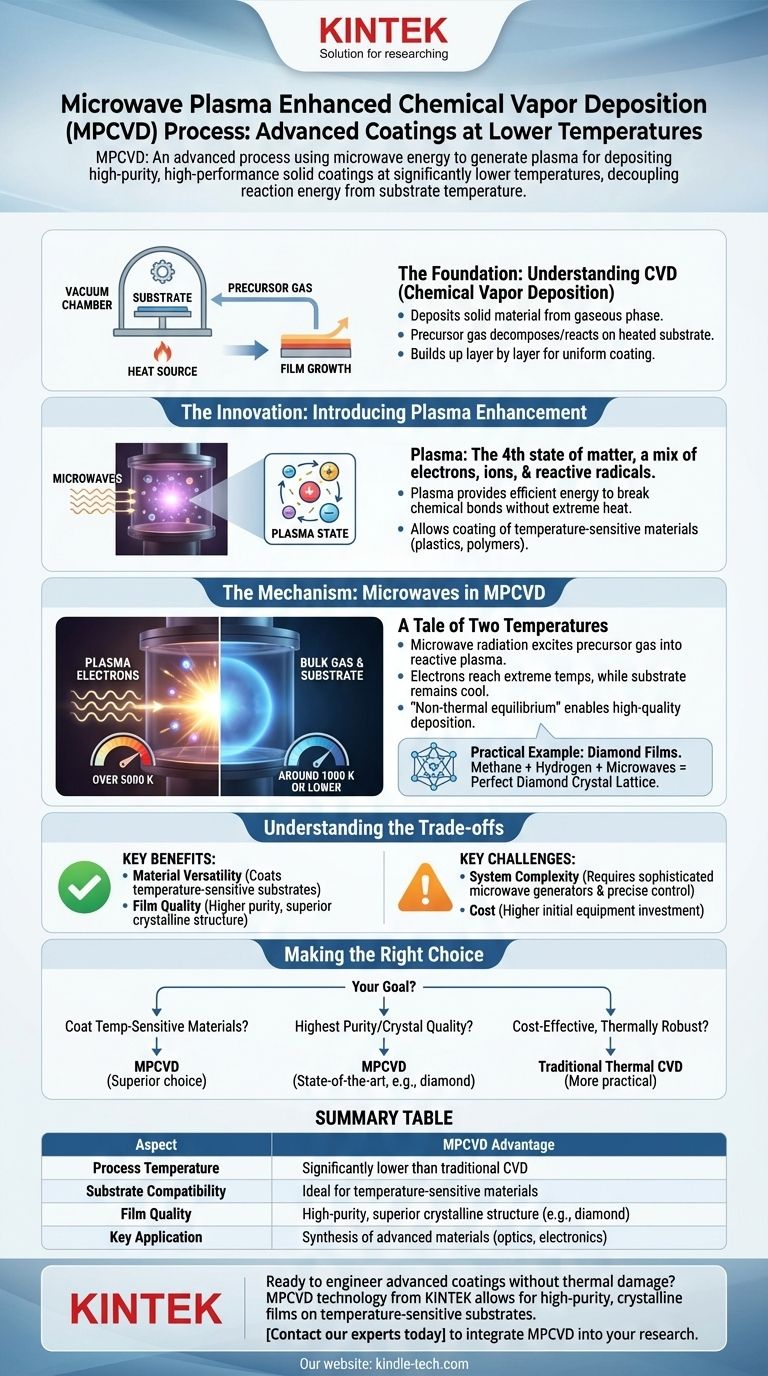

The Foundation: Understanding Chemical Vapor Deposition (CVD)

The Basic Principle

Chemical Vapor Deposition (CVD) is a method for depositing a solid material from a gaseous phase onto a substrate. It is a cornerstone technique for producing high-quality coatings and thin films.

The Core Steps

The process involves placing a component, or substrate, inside a vacuum chamber. A volatile precursor gas containing the required chemical elements is then introduced.

When heated to a specific reaction temperature, this precursor gas decomposes or reacts on the substrate's surface. This chemical reaction leaves behind a solid material, forming a thin film that bonds directly to the surface.

Film Growth

Over time, this deposited material builds up layer by layer. The process is engineered to create a uniform, dense, and highly adherent coating over the entire exposed surface of the component.

The Innovation: Introducing Plasma Enhancement

What is Plasma?

Plasma is often called the fourth state of matter. In the context of MPCVD, it is a gas that has been energized to the point where it contains a mix of electrons, ions, and highly reactive neutral radicals.

Why Use Plasma?

In traditional CVD, immense heat is the only tool used to break down the precursor gas. Plasma provides an alternative, highly efficient energy source. The energetic particles within the plasma can break the chemical bonds in the precursor gas without requiring extreme temperatures for the entire chamber.

The Low-Temperature Advantage

This activation by plasma allows the deposition process to occur at a much lower substrate temperature. This dramatically expands the range of materials that can be coated, including temperature-sensitive plastics, polymers, and certain alloys.

The Mechanism: The Role of Microwaves in MPCVD

Generating the Plasma

In MPCVD, microwave radiation is channeled into the vacuum chamber. This focused energy is absorbed by the precursor gas, exciting its atoms and molecules and transforming it into a reactive plasma state.

A Tale of Two Temperatures

A key characteristic of this process is the vast difference between the temperature of the plasma's electrons and the overall gas temperature. The electrons can reach temperatures exceeding 5000 K, providing ample energy for chemical reactions.

Simultaneously, the bulk gas and the substrate itself can remain at a much cooler temperature, often around 1000 K or lower. This "non-thermal equilibrium" is what enables high-quality deposition without high heat.

A Practical Example: Diamond Films

MPCVD is the leading method for synthesizing high-quality diamond films. Precursor gases like methane are mixed with hydrogen and energized by microwaves. The resulting plasma contains the precise reactive carbon and hydrogen species necessary to build a perfect diamond crystal lattice on a substrate.

Understanding the Trade-offs

Key Benefit: Material Versatility

The primary advantage is the ability to coat temperature-sensitive substrates that would be damaged or destroyed in a high-temperature thermal CVD process.

Key Benefit: Film Quality

The highly reactive nature of the plasma often leads to the formation of higher-purity and more perfectly crystalline films compared to other methods. This is critical for applications in optics, electronics, and wear-resistant tools.

Key Challenge: System Complexity

MPCVD systems are more complex than traditional thermal CVD furnaces. They require sophisticated microwave generators, waveguides, and precise control over plasma physics, gas flow, and vacuum conditions.

Key Challenge: Cost

The complexity and specialized components, such as the microwave power source and reactor design, generally make MPCVD a more expensive technology in terms of initial equipment investment.

Making the Right Choice for Your Goal

The decision to use MPCVD depends entirely on the specific requirements of the material and the desired outcome.

- If your primary focus is coating temperature-sensitive materials: MPCVD is the superior choice, as it protects the substrate from thermal damage.

- If your primary focus is achieving the highest possible film purity and crystal quality: MPCVD is the state-of-the-art method, especially for materials like diamond and other advanced ceramics.

- If your primary focus is cost-effective coating of thermally robust materials: Traditional thermal CVD may be a more practical and economical solution.

Ultimately, MPCVD provides a powerful capability to engineer advanced materials that are simply not possible to create with heat-based methods alone.

Summary Table:

| Aspect | MPCVD Advantage |

|---|---|

| Process Temperature | Significantly lower than traditional CVD |

| Substrate Compatibility | Ideal for temperature-sensitive materials (e.g., plastics, polymers) |

| Film Quality | High-purity, superior crystalline structure (e.g., diamond films) |

| Key Application | Synthesis of advanced materials like diamond for optics and electronics |

Ready to engineer advanced coatings without thermal damage?

MPCVD technology from KINTEK allows you to deposit high-purity, crystalline films on even the most temperature-sensitive substrates. Whether your lab is focused on developing next-generation electronics, wear-resistant tools, or optical components, our expertise in lab equipment can help you achieve superior material performance.

Contact our experts today to discuss how an MPCVD system can be integrated into your research and development workflow.

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the uses of lab-grown diamonds? From Jewelry to High-Tech Applications

- What is microwave plasma chemical vapor deposition? A Guide to High-Purity Diamond Film Growth

- Can a diamond be created in a laboratory? The Science Behind Genuine Lab-Grown Diamonds

- What are the applications of CVD diamonds? From Jewelry to High-Tech Tools

- What are synthetic diamonds used for in industry? Powering High-Tech Tools and Electronics

- Do lab diamonds break easily? No, They're as Durable as Mined Diamonds

- What is the difference between RF and microwave plasma? Choose the Right Plasma for Your Process

- What's the difference between CVD and HPHT? Choosing the Right Lab-Grown Diamond Method