In short, the microwave plasma method is a high-energy process that uses microwave radiation to excite gases into a reactive state of matter known as plasma. This plasma is then used to synthesize and deposit highly pure materials, most notably for growing high-quality lab-grown diamonds atom by atom in a controlled chamber.

At its core, the microwave plasma method is about precisely controlling energy to break down simple source gases into their fundamental, reactive components. This allows for the controlled construction of advanced materials with exceptional purity and structure.

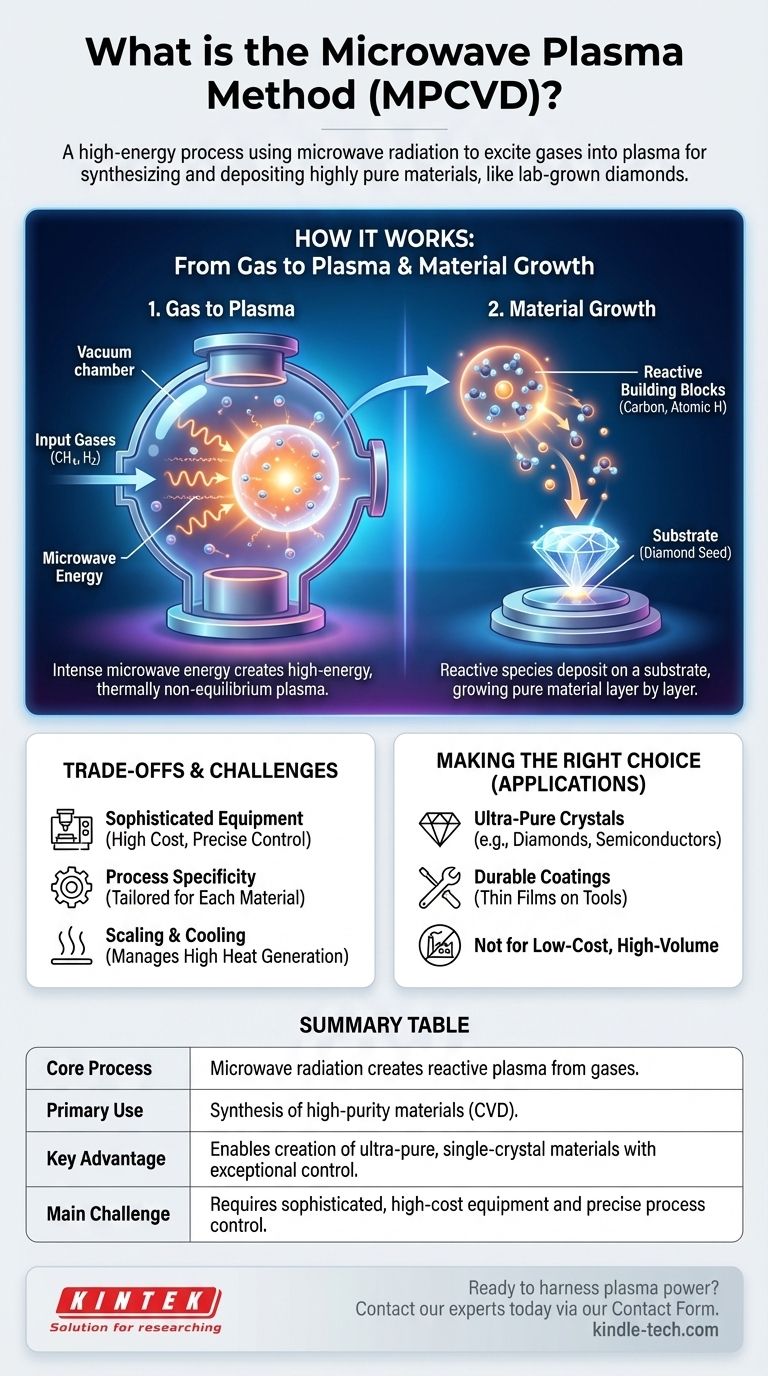

How the Process Works: From Gas to Plasma

The microwave plasma method, often referred to as Microwave Plasma Chemical Vapor Deposition (MPCVD), is a sophisticated technique. It transforms common gases into the building blocks for advanced materials through a series of controlled steps.

The Core Ingredients

The process begins by introducing specific gases into a vacuum chamber. For diamond growth, this is typically a mixture of methane (CH4), which provides the carbon atoms, and hydrogen (H2). Other gases like nitrogen or argon can be added to fine-tune the properties of the final material.

The Role of Microwave Energy

Once the gases are in the chamber, they are bombarded with powerful microwave radiation. This is the same type of energy used in a microwave oven, but it is focused with much higher intensity. This energy is the catalyst that drives the entire reaction.

Creating the Plasma State

The intense microwave energy strips electrons from the gas molecules, creating a glowing ball of high-energy plasma. This plasma is a unique state of matter—an ionized gas containing a mix of electrons, ions, neutral atoms, and molecular fragments.

A key feature of this plasma is its thermal non-equilibrium. The electrons can reach incredibly high temperatures (over 5,000 K), while the overall gas temperature remains much lower (around 1,000 K). This allows for high-energy chemical reactions to occur without melting the equipment.

The Mechanism of Material Growth

Once the plasma is formed, the real construction begins. The highly energetic environment is perfect for breaking down stable molecules and creating an ideal environment for deposition.

Generating Reactive Building Blocks

The energy within the plasma is sufficient to break the strong bonds in the source gas molecules. Methane (CH4) is split apart, creating reactive carbonaceous species—the essential building blocks for the new material. Simultaneously, hydrogen molecules (H2) are split into highly reactive atomic hydrogen.

Deposition on a Substrate

These reactive carbon atoms then deposit onto a prepared surface, known as a substrate. In diamond synthesis, this is often a tiny, pre-existing diamond seed. The carbon atoms arrange themselves according to the crystal structure of the seed, causing a new, larger, high-purity diamond to grow layer by layer.

Understanding the Trade-offs

While powerful, the microwave plasma method involves specific challenges and is not a universal solution for all material synthesis needs.

Sophisticated Equipment

Generating and containing a stable, high-energy plasma inside a vacuum requires complex and often expensive equipment. Maintaining the precise control over gas flow, pressure, and microwave power needed for high-quality results demands advanced engineering.

Process Specificity

The method is highly tailored. The choice of gases, temperature, pressure, and microwave frequency are all fine-tuned for the specific material being grown. A system optimized for creating diamonds is not immediately suitable for depositing a different type of thin film without significant recalibration.

Scaling and Cooling

While the technology can be scaled for larger production, managing the heat generated by the process can be a challenge. High-power systems may require auxiliary cooling to operate continuously and reliably, adding another layer of complexity to the operation.

Making the Right Choice for Your Goal

The microwave plasma method is a specialized tool designed for applications where purity and crystalline quality are paramount.

- If your primary focus is creating ultra-pure, single-crystal materials: This method offers unparalleled control for growing materials like gemstone-quality diamonds or semiconductors.

- If your primary focus is applying durable, high-performance coatings: The technique is excellent for depositing thin films of super-hard materials like diamond-like carbon onto tools or industrial components.

- If your primary focus is low-cost, high-volume manufacturing: The high equipment cost and process complexity may make other methods, such as sintering or conventional casting, more appropriate for less demanding applications.

Ultimately, the microwave plasma method represents a powerful capability in modern materials science, enabling the creation of materials that are impossible to form through traditional means.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Process | Uses microwave radiation to create a reactive plasma from gases. |

| Primary Use | Synthesis of high-purity materials (e.g., diamonds) via Chemical Vapor Deposition (CVD). |

| Key Advantage | Enables creation of ultra-pure, single-crystal materials with exceptional control. |

| Main Challenge | Requires sophisticated, high-cost equipment and precise process control. |

Ready to harness the power of plasma for your materials research?

KINTEK specializes in providing the advanced lab equipment and consumables needed for sophisticated processes like Microwave Plasma Chemical Vapor Deposition (MPCVD). Whether you are growing high-purity diamonds or developing next-generation thin-film coatings, our expertise and reliable products support your most demanding applications.

Contact our experts today via our Contact Form to discuss how we can help you achieve unparalleled precision and purity in your lab.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Can a diamond tester tell the difference between lab grown and natural diamonds? The Surprising Truth

- What are the uses of diamond in industry? Solving Extreme Engineering Challenges

- What is the demand of CVD diamonds? Driven by Ethics, Purity, and Affordability

- What is the fluorescence of a CVD diamond? A Guide to Its Unique Glow and Purpose

- What is the chemical vapor deposition (CVD) method of diamond growth? Master Precision with KINTEK

- How are lab-grown diamonds created? Discover the HPHT and CVD Manufacturing Process

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are the defects in CVD diamond? A Guide to Identifying and Assessing Quality