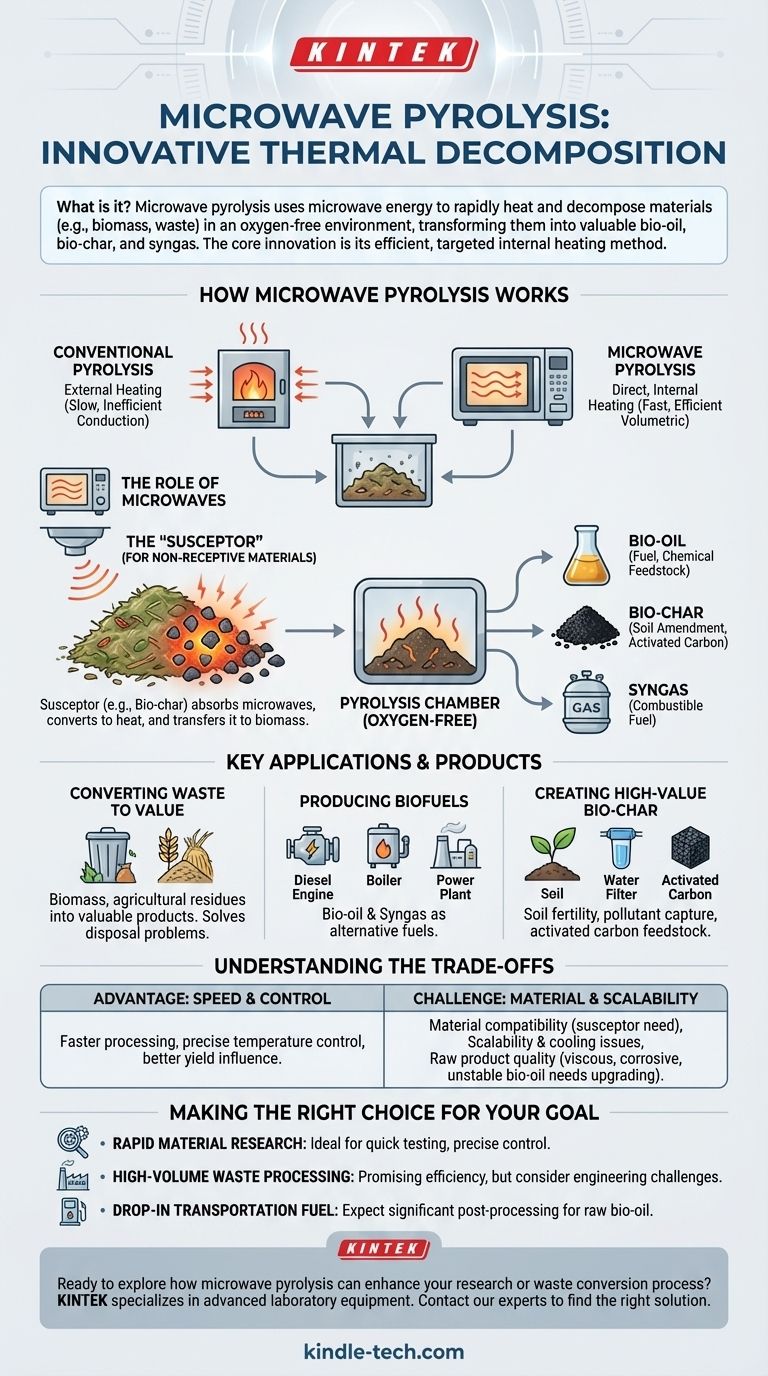

In short, microwave pyrolysis is a process that uses microwave energy to rapidly heat and decompose materials, such as biomass or waste, in an oxygen-free environment. This method transforms the material into valuable products like bio-oil, bio-char, and syngas by leveraging a highly efficient and targeted heating mechanism.

The core innovation of microwave pyrolysis is its heating method. Instead of heating from the outside-in like a conventional furnace, microwaves can heat materials more uniformly and selectively, often using a microwave-absorbing additive to kickstart the process for materials that don't heat on their own.

How Microwave Pyrolysis Works

To understand the method, it's essential to break down the core process and the unique role that microwave energy plays.

The Core Principle: Pyrolysis

Pyrolysis is thermal decomposition in the absence of oxygen. When you heat organic material without oxygen, it doesn't burn; instead, its chemical bonds break down, reforming into different substances.

The primary outputs are bio-oil (a liquid fuel), bio-char (a charcoal-like solid), and syngas (a mixture of combustible gases).

The Role of Microwave Energy

Conventional pyrolysis furnaces heat a chamber from the outside, slowly transferring thermal energy to the material inside. This can be slow and inefficient.

Microwave pyrolysis, however, heats the material directly. This internal and volumetric heating can be much faster and more energy-efficient, offering greater control over the final product characteristics.

The "Susceptor" for Non-Receptive Materials

Many target materials, like dry biomass, do not absorb microwave energy effectively on their own. To solve this, a susceptor is often mixed in.

A susceptor is a material that readily absorbs microwaves and converts them into thermal heat (e.g., bio-char or silicon carbide). This hot susceptor then transfers its heat to the surrounding biomass through conduction, driving the pyrolysis reaction efficiently.

Key Applications and Products

Microwave pyrolysis is primarily used in industries focused on waste material processing, chemical production, and biofuel generation.

Converting Waste to Value

The method is highly effective for converting various forms of waste, particularly biomass like agricultural residues, into valuable products. This turns a disposal problem into a resource opportunity.

Producing Biofuels

The resulting bio-oil and syngas can be used as fuel. Pyrolysis oil can potentially serve as an alternative to fuel oil in diesel engines, boilers, and large power plants.

Creating High-Value Bio-char

The solid bio-char is a valuable product. It can be used as a soil amendment to improve fertility, as a sorbent for capturing pollutants, or as a feedstock for producing high-grade activated carbon.

Understanding the Trade-offs

While promising, microwave pyrolysis has a specific set of advantages and challenges that determine its suitability for a given application.

Advantage: Speed and Control

The direct, rapid heating allows for much faster processing times compared to conventional methods. This speed also provides finer control over the reaction temperature, influencing the yield of oil, char, or gas.

Challenge: Material Compatibility

The effectiveness of the process depends heavily on the material's ability to absorb microwaves. For materials that don't, the need for a susceptor adds a layer of complexity and cost to the process.

Challenge: Scalability and Cooling

While the technology is well-suited for research and smaller-scale operations, scaling it for large industrial volumes presents engineering challenges. Efficiently cooling the equipment can become a significant factor, potentially requiring auxiliary cooling systems.

Challenge: Raw Product Quality

Like oil from any pyrolysis method, the raw bio-oil produced is often highly viscous, corrosive, and chemically unstable. It typically requires significant upgrading before it can be used as a direct replacement for conventional transportation fuels.

Making the Right Choice for Your Goal

Microwave pyrolysis is a powerful tool, but its application must align with your primary objective.

- If your primary focus is rapid material research: This method is ideal due to its fast heating rates and precise temperature control, allowing for quick testing of different feedstocks.

- If your primary focus is high-volume waste processing: The technology is promising for its efficiency, but you must carefully evaluate the engineering challenges related to scalability and cooling.

- If your primary focus is producing drop-in transportation fuel: Be prepared for post-processing, as the raw bio-oil requires significant upgrading to address its corrosiveness and instability.

Ultimately, microwave pyrolysis represents a more precise and potentially efficient pathway for converting waste into valuable resources.

Summary Table:

| Feature | Microwave Pyrolysis | Conventional Pyrolysis |

|---|---|---|

| Heating Method | Direct, internal, volumetric heating | External, conduction-based heating |

| Speed | Rapid | Slower |

| Energy Efficiency | High (targeted heating) | Lower (heat loss) |

| Control | Precise temperature control | Less precise |

| Scalability | Challenging for large volumes | More established for large scale |

Ready to explore how microwave pyrolysis can enhance your research or waste conversion process? KINTEK specializes in advanced laboratory equipment for pyrolysis and other thermal processes. Our experts can help you select the right tools to efficiently produce bio-oil, bio-char, and syngas from your specific biomass or waste materials. Contact our team today to discuss your application and discover the right solution for your lab's needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why should glass-ceramic green bodies be placed in a precision drying oven? Ensure Structural Integrity & High Yield

- Why argon is the usual gas for the sputtering processes? Optimize Your Thin Film Deposition

- What does a heat treatment do? Unlock Your Material's Full Potential

- What is DC magnetron sputtering? A High-Speed Method for Thin-Film Deposition

- How does a constant-temperature laboratory shaker support microbial toxicity testing? Ensure Accurate Nanocomposite Data

- What does CIP stand for Crip? Understanding the Meaning of Crip In Peace

- Is there a difference between a kiln and a furnace? Choose the Right Tool for Your Material

- What is the source of bio-oil? Unlock Renewable Energy from Biomass