While there is no single "most" PVD coating, the term often refers to the most common and versatile materials used in the industry. For general-purpose applications, Titanium Nitride (TiN) is arguably the most recognizable and historically significant PVD coating, widely used for its balance of hardness, wear resistance, and distinctive gold color.

The question isn't which PVD coating is "best," but which one is right for your specific goal. PVD is a family of processes used to apply a wide range of materials, each tailored with unique properties like hardness, friction, or corrosion resistance to solve a specific engineering problem.

What is PVD Coating? A Foundational Overview

Physical Vapor Deposition (PVD) is not a single material but a sophisticated vacuum coating technique. It's used to apply an exceptionally thin yet highly durable film onto a surface.

The Core Principle: From Solid to Thin Film

At its heart, the PVD process involves taking a solid source material, called a "target," and vaporizing it inside a high-vacuum chamber. These vaporized atoms then travel and condense onto the part you wish to coat, forming a strong, dense, and uniform layer one atom at a time.

The Key Characteristics

PVD coatings are remarkably thin, often measuring between 0.5 and 5 micrometers. Despite their microscopic thickness, they dramatically improve the part's surface hardness, reduce wear, and provide excellent resistance to corrosion and chemicals.

The Process Environment

This entire process occurs under a vacuum at high temperatures, typically ranging from 250°C to 750°C (480°F to 1380°F). This high-energy environment ensures the coating bonds with extreme tenacity to the substrate's surface.

The Two Dominant PVD Processes

The term "PVD" describes a family of techniques. The two most common industrial processes are Sputtering and Arc Evaporation, which differ in how they vaporize the source material.

Sputtering: The Precise & Uniform Method

In sputtering, the target material is bombarded with energetic ions (often argon), which physically "knocks off" or sputters atoms. This method, especially magnetron sputtering, is known for producing exceptionally smooth, uniform, and dense coatings.

Arc Evaporation: The Fast & Energetic Method

Cathodic Arc Evaporation uses a high-current electric arc to vaporize the target material. This creates a highly ionized vapor that is propelled toward the substrate with significant energy, resulting in an extremely hard and strongly adhered coating.

Common PVD Coating Materials and Their Purpose

The true power of PVD lies in the ability to deposit different materials—and even create new compounds by introducing reactive gases like nitrogen or oxygen into the chamber.

Titanium Nitride (TiN): The All-Purpose Gold Standard

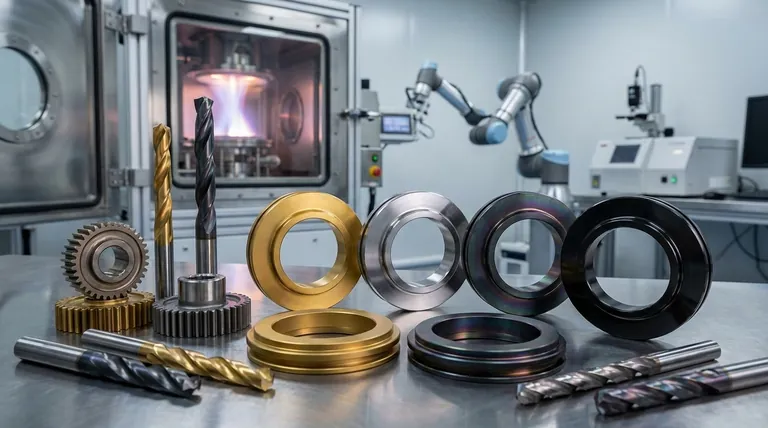

This is the classic, gold-colored coating often seen on cutting tools and drill bits. TiN provides a great all-around improvement in hardness and wear resistance and serves as a reliable workhorse for many applications.

Chromium Nitride (CrN): The Corrosion & Sticking Specialist

CrN is harder and more corrosion-resistant than TiN. Its silver-like appearance and lower coefficient of friction make it an excellent choice for applications where sticking, galling, or corrosion are primary concerns, such as in plastic molding and food processing.

Titanium Aluminum Nitride (TiAlN): The High-Temperature Performer

By adding aluminum to the TiN matrix, TiAlN forms a self-protecting oxide layer at high temperatures. This makes it a superior coating for high-speed machining and other applications where extreme heat would cause a standard TiN coating to fail.

Diamond-Like Carbon (DLC): The Low-Friction Champion

DLC coatings are a class of amorphous carbon materials that exhibit some of the unique properties of natural diamond. They are exceptionally hard and have an extremely low coefficient of friction, making them ideal for high-performance engine components, bearings, and medical implants to reduce wear and friction.

Understanding the Trade-offs

While powerful, PVD technology is not a universal solution. Understanding its limitations is key to using it effectively.

Process Temperature Limitations

The high temperatures required for PVD mean that it cannot be used on substrates with low melting points, such as most plastics or low-temperature alloys, without risking damage or deformation to the part.

Line-of-Sight Deposition

Because the vaporized atoms travel in a straight line, PVD is a "line-of-sight" process. Coating complex internal geometries or deep, narrow holes can be challenging and requires sophisticated part rotation and positioning to ensure even coverage.

Cost vs. Performance Balance

PVD is a high-technology vacuum process that requires significant capital investment and expertise. The performance benefits must be weighed against the cost, making it most suitable for applications where improved durability, reduced friction, or enhanced lifespan provide a clear return on investment.

How to Choose the Right PVD Coating

Selecting the correct coating requires matching the material's properties to your primary objective.

- If your primary focus is general-purpose wear resistance: Titanium Nitride (TiN) is an excellent and cost-effective starting point.

- If your primary focus is preventing corrosion or material sticking: Chromium Nitride (CrN) offers superior protection and lubricity.

- If your primary focus is high-temperature machining or cutting: Titanium Aluminum Nitride (TiAlN) provides the necessary thermal stability to maintain hardness under heat.

- If your primary focus is minimizing friction on moving parts: Diamond-Like Carbon (DLC) coatings provide an unmatched combination of hardness and low friction.

Ultimately, the most effective PVD coating is the one engineered precisely for the problem you need to solve.

Summary Table:

| Coating Material | Key Properties | Common Applications |

|---|---|---|

| Titanium Nitride (TiN) | High hardness, wear resistance, gold color | Cutting tools, drill bits |

| Chromium Nitride (CrN) | Superior corrosion resistance, low friction | Plastic molding, food processing |

| Titanium Aluminum Nitride (TiAlN) | Excellent high-temperature stability | High-speed machining |

| Diamond-Like Carbon (DLC) | Extreme hardness, very low friction | Engine components, medical implants |

Ready to enhance your components with the perfect PVD coating?

At KINTEK, we specialize in advanced lab equipment and consumables for precise PVD coating applications. Whether you're developing cutting tools, medical devices, or high-performance industrial parts, our solutions ensure superior hardness, wear resistance, and durability.

Let our experts help you select and apply the ideal coating—like TiN, CrN, TiAlN, or DLC—to meet your specific needs.

Contact us today to discuss your project and discover how KINTEK can elevate your laboratory's capabilities!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- Is diamond coating worth it? Maximize Component Life and Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance