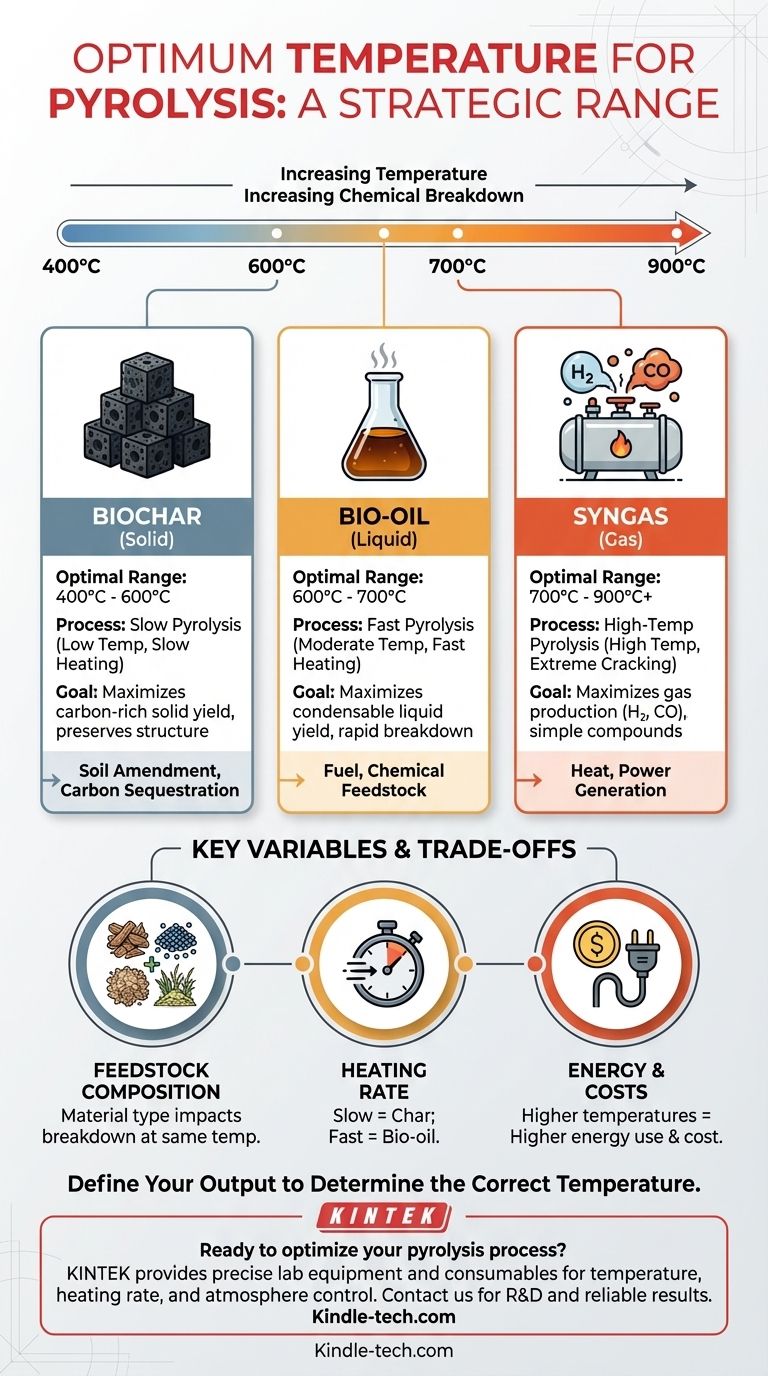

The optimal temperature for pyrolysis is not a single number, but rather a strategic range chosen based on the desired end product. While the process typically operates between 400°C and 900°C, the specific temperature you target directly controls whether you maximize the yield of biochar, bio-oil, or syngas.

The concept of an "optimum" temperature is a function of your goal. Lower temperatures favor solid biochar, moderate temperatures favor liquid bio-oil, and high temperatures favor flammable syngas.

How Temperature Controls Pyrolysis Products

Pyrolysis is the thermal decomposition of material in the absence of oxygen. As you increase the temperature, the chemical bonds within the feedstock break down more completely, leading to different primary outputs.

For Maximizing Biochar (Solid)

To produce the highest yield of biochar, a stable, carbon-rich solid, lower temperatures are required. This process is often called slow pyrolysis.

The target temperature range is typically between 400°C and 600°C. At these temperatures, the decomposition is less severe, preserving more of the original carbon structure as a solid char.

For Maximizing Bio-oil (Liquid)

If the primary goal is to produce bio-oil (also known as pyrolysis oil or bio-crude), a moderate temperature range combined with a very fast heating rate is necessary.

This "fast pyrolysis" is most effective between 600°C and 700°C. This window provides enough energy to quickly break down biomass into condensable vapors, which are then rapidly cooled to form a liquid.

For Maximizing Syngas (Gas)

To maximize the production of syngas, a mixture of hydrogen and carbon monoxide, high temperatures are essential.

This requires a temperature range above 700°C, often approaching 900°C or higher. At these extreme temperatures, longer-chain organic molecules are thoroughly cracked into the simplest, most stable gaseous compounds.

Understanding the Trade-offs

Choosing a temperature is not the only factor. The efficiency and outcome of pyrolysis depend on a balance of interconnected variables.

Feedstock Composition Matters

The type of material being processed has a significant impact. Woody biomass, plastics, and agricultural waste all have different chemical compositions and will break down differently at the same temperature. An optimal temperature for pine wood may not be optimal for waste plastic.

Heating Rate is a Critical Variable

The speed at which the feedstock reaches the target temperature is just as important as the temperature itself.

A slow heating rate gives volatile compounds time to escape, favoring char formation. A fast heating rate causes rapid decomposition, favoring the production of vapors that can be condensed into bio-oil.

Energy and Economic Costs

Higher temperatures require significantly more energy input, which increases operational costs. The "optimum" temperature must also be economically viable, balancing the value of the desired product against the energy needed to produce it.

Making the Right Choice for Your Goal

Your target temperature should be determined by your primary objective.

- If your primary focus is producing biochar for soil amendment or carbon sequestration: Target a lower temperature range of 400-600°C with a slower heating rate.

- If your primary focus is creating liquid bio-oil as a potential fuel or chemical feedstock: Target a moderate range of 600-700°C with a very fast heating rate.

- If your primary focus is generating syngas for heat or power generation: Target a high temperature of 700-900°C to ensure complete thermal cracking into gaseous components.

Ultimately, defining your desired output is the first and most critical step in determining the correct pyrolysis temperature.

Summary Table:

| Target Product | Optimal Temperature Range | Process Type | Key Characteristic |

|---|---|---|---|

| Biochar (Solid) | 400°C - 600°C | Slow Pyrolysis | Maximizes carbon-rich solid yield |

| Bio-oil (Liquid) | 600°C - 700°C | Fast Pyrolysis | Maximizes condensable liquid yield |

| Syngas (Gas) | 700°C - 900°C+ | High-Temp Pyrolysis | Maximizes gas production (H₂, CO) |

Ready to optimize your pyrolysis process?

At KINTEK, we specialize in providing the precise lab equipment and consumables you need to accurately control pyrolysis temperature, heating rate, and atmosphere. Whether your goal is R&D for biochar, bio-oil, or syngas production, our reactors and furnaces deliver the reliability and performance required for repeatable results.

Let our experts help you select the right equipment to achieve your specific yield targets. Contact us today to discuss your application!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the common applications for a tube furnace? Essential for Heat Treatment, Synthesis, and Purification

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- What are the advantages of a tube furnace? Achieve Superior Thermal Control and Purity

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness