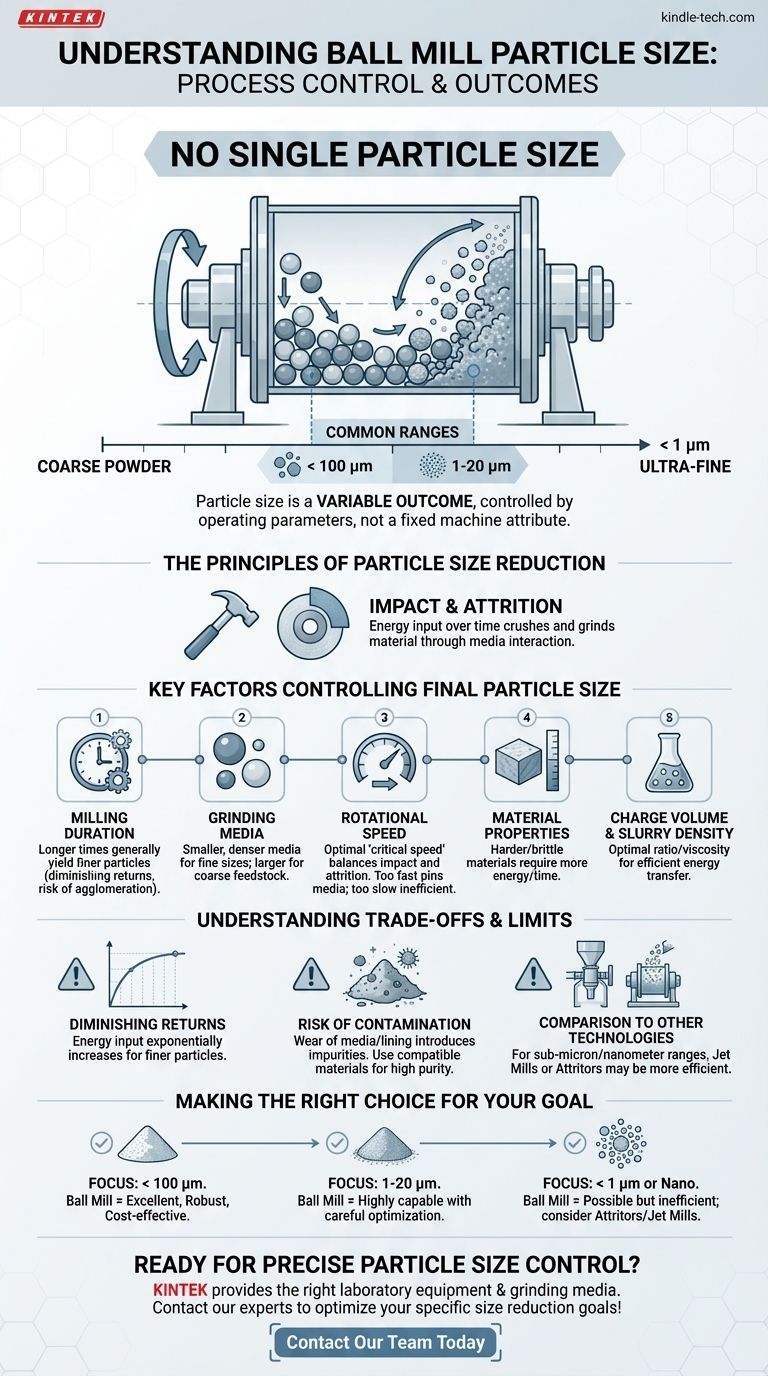

Ultimately, there is no single particle size for a ball mill. The final particle size is not a fixed attribute of the machine but a highly variable outcome controlled by the setup and operating parameters. While it's common to achieve particle sizes below 100 microns (µm), ball mills are frequently used in laboratory and industrial settings to reduce starting powders down into the 1-20 micron range and even finer with sufficient processing time.

A ball mill's effectiveness is defined by its operational parameters, not a single output number. The crucial question isn't "what particle size does it produce?" but rather "how do I control the process to achieve my target particle size?"

The Principles of Particle Size Reduction

A ball mill is a type of grinder that uses a rotating cylinder containing grinding media—typically ceramic or steel balls. As the cylinder rotates, the media cascades from the top, crushing and grinding the material through impact and attrition.

This process is fundamentally a function of energy input over time. The more energy effectively transferred to the material, the smaller the resulting particles will be, up to a practical limit.

Key Factors Controlling Final Particle Size

Achieving a specific particle size distribution requires a clear understanding of the variables you can control. The final result is a balance of these key factors.

Milling Duration

This is the most straightforward variable. Longer milling times generally lead to finer particles. However, the rate of size reduction diminishes over time, and excessive milling can sometimes lead to particle agglomeration.

Grinding Media Characteristics

The size, density, and material of the grinding balls are critical. Smaller, denser media provide more surface contact and are more effective for achieving very fine particle sizes. Larger media are better for breaking down coarse initial feedstock.

Mill Rotational Speed

There is an optimal rotational speed, often referred to as the "critical speed." Operating too slowly results in inefficient grinding (attrition only). Operating too fast causes the media to be pinned to the cylinder wall by centrifugal force, stopping the grinding action entirely.

Material Properties

The inherent properties of the material being milled, such as its hardness and brittleness, dictate how easily it will fracture. Harder materials require more energy and time to achieve the same size reduction as softer materials.

Charge Volume and Slurry Density

The ratio of material to grinding media is crucial for efficient energy transfer. Similarly, in wet milling applications, the viscosity and density of the slurry (the mixture of powder and liquid) significantly impact the grinding kinetics.

Understanding the Trade-offs and Limits

While powerful, ball mills are not without limitations. Understanding these is essential for process optimization and deciding if it is the right tool for your goal.

The Point of Diminishing Returns

As particles become finer, the energy required to fracture them further increases exponentially. At a certain point, the energy input primarily generates heat or causes particles to re-agglomerate rather than achieving further size reduction.

Comparison to Other Technologies

Ball mills are exceptionally effective for grinding down to the micron level (e.g., 1-100 µm). However, for producing particles consistently in the sub-micron or nanometer range, other technologies like jet mills or media mills (attritors) are often more efficient and controllable.

Risk of Contamination

The grinding media and the mill lining itself will wear down over time. This wear introduces contamination into your material. For high-purity applications, such as pharmaceuticals or advanced ceramics, this is a critical consideration that may require using media made of the same material as the powder (e.g., zirconia media for a zirconia powder).

Making the Right Choice for Your Goal

To determine if a ball mill is right for you, consider your final objective.

- If your primary focus is general size reduction to < 100 µm: A ball mill is an excellent, robust, and cost-effective choice.

- If your primary focus is achieving a specific size in the 1-20 µm range: A ball mill is highly capable, but success requires careful optimization of milling time, media, and speed.

- If your primary focus is producing ultra-fine particles (< 1 µm or nanoparticles): A ball mill can do this, but it may be inefficient; you should evaluate specialized equipment like attritors or jet mills.

Ultimately, mastering your ball milling process is about systematically controlling the inputs to achieve a predictable and repeatable output.

Summary Table:

| Factor | Impact on Particle Size |

|---|---|

| Milling Duration | Longer times generally yield finer particles, but with diminishing returns. |

| Grinding Media Size/Density | Smaller, denser media are more effective for achieving fine and ultra-fine grinds. |

| Rotational Speed | Must be optimized (critical speed) for efficient impact grinding versus simple attrition. |

| Material Hardness | Harder materials require more energy and time to achieve the same size reduction. |

| Charge/Slurry Density | Affects the efficiency of energy transfer from the media to the material. |

Ready to achieve precise particle size control in your lab?

At KINTEK, we specialize in providing the right laboratory equipment, including ball mills and grinding media, to meet your specific size reduction goals. Whether you're processing materials down to the micron level or exploring finer grinds, our experts can help you select and optimize the perfect solution for your application.

Contact our team today to discuss your project and discover how KINTEK can enhance your lab's capabilities and efficiency!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What grinding media is used in a ball mill? Select the Right Media for Maximum Efficiency and Purity

- What are the disadvantages of ball milling? Key Limitations in Particle Size Reduction

- What is the primary function of mechanical grinding equipment in the physical modification of lignin?

- How does mechanical ball milling compare to sol-gel for oxide coating? Streamline Your Lab Equipment Workflow

- Why are polyurethane grinding jars and agate grinding balls preferred for milling B4C? Protect Material Purity

- What materials are used in ball milling? Choose the Right Grinding Media for Purity & Efficiency

- Can zirconia be milled? Mastering the Green-State vs. Sintered Milling Process

- What is a ball mill used in pharmaceutical industry? Achieve Superior Particle Size Reduction for Drug Efficacy